An annular flue gas denitrification device for a sandwich furnace

A furnace and denitration technology, which is applied to combined devices, gas treatment, separation methods, etc., can solve the problems of insufficient contact between flue gas and catalyst, increased catalyst wear, uneven distribution of flue gas, etc., and achieves significant denitration effect and sufficient contact time. , The effect of uniform distribution of intake air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

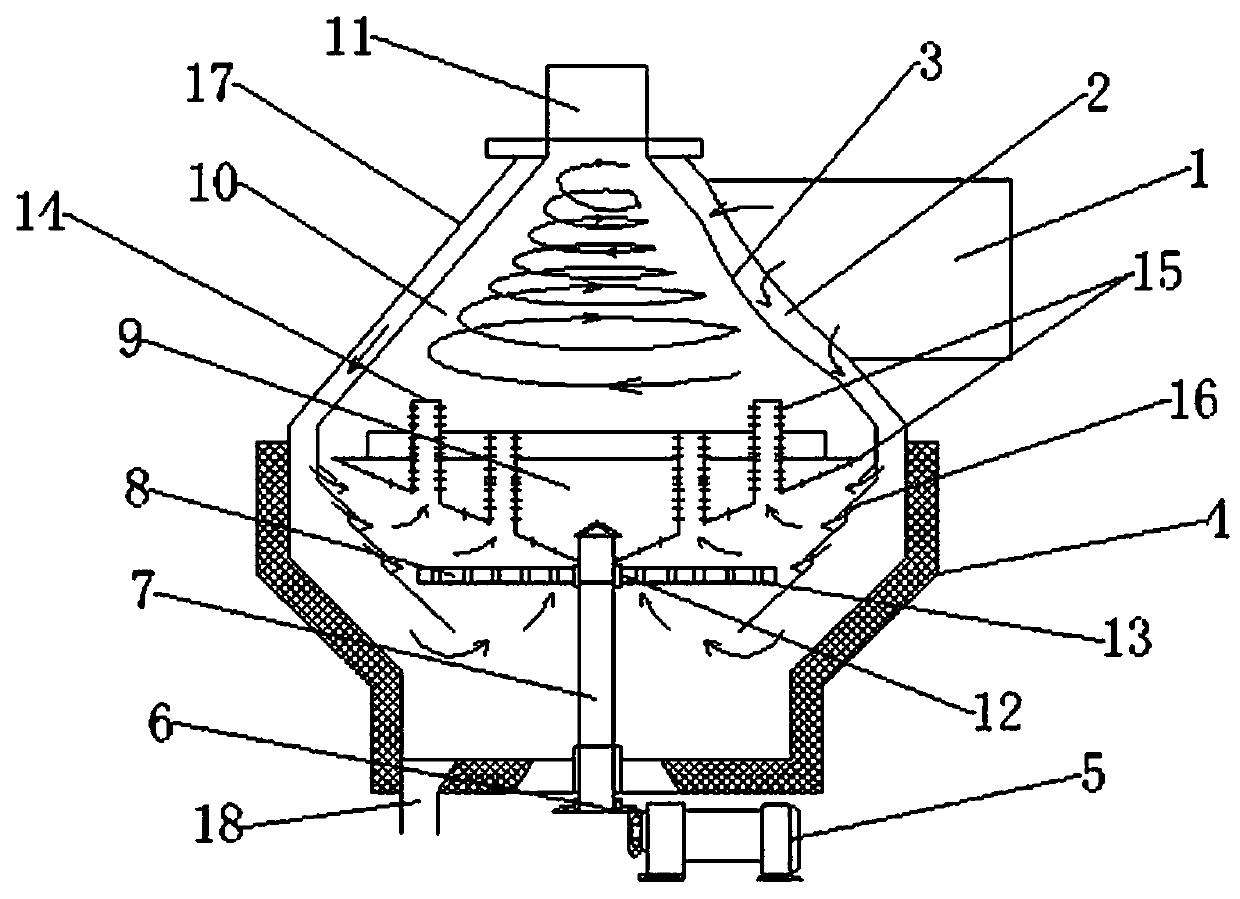

[0019] An annular flue gas denitrification device for a sandwich furnace, comprising a flue gas inlet 1, a flue gas channel 2, a furnace interlayer 3, an insulation layer 4, a motor 5, a transmission gear 6, a transmission shaft 7, an oscillating resistance dust filter 8, and a grate assembly 9. The furnace 10, the flue gas outlet 11, the outer furnace wall 17 and the ash outlet 18 are characterized in that: the oscillating resistance dust filter 8 and the transmission shaft 7 are connected through the eccentric oscillator 12, and the oscillating resistance dust filter 8 is evenly distributed with filter dust Mesh 13, large denitrification holes 14 are evenly distributed on the grate assembly 9, small denitrification holes 15 are also distributed on the surface of the denitrification large holes 14 and the grate assembly 9, and annular flue gas inlets are evenly distributed in the lower half of the furnace interlayer 3 16, while the surface of the grate assembly 9, the large de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com