Rotor blade precision forging structure and preparation method thereof

A precision forging technology for rotor blades, applied in the direction of blade support components, mechanical equipment, engine components, etc., can solve the deformation of the inlet and exhaust edges of the blade tip section, cannot effectively guarantee the processing quality, and the inlet and exhaust edges are easy to tear and deform and other problems, to achieve the effect of ensuring contour, simple structure and increasing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

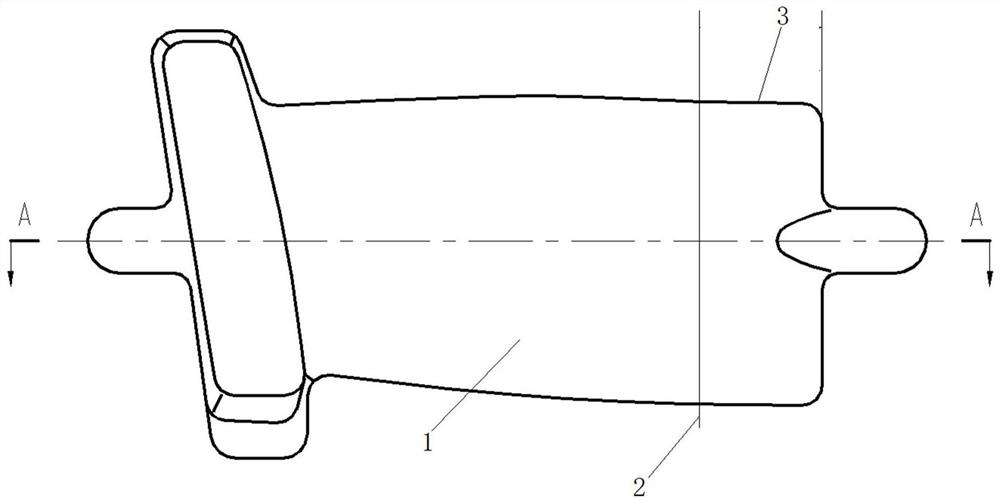

[0029] A method for preparing a precision forging structure of a rotor blade, comprising the following steps,

[0030] S1, according to the structure of the rotor blade precision forging, create a tool plane within the range of the homeopathic extension of the rotor blade precision forging body;

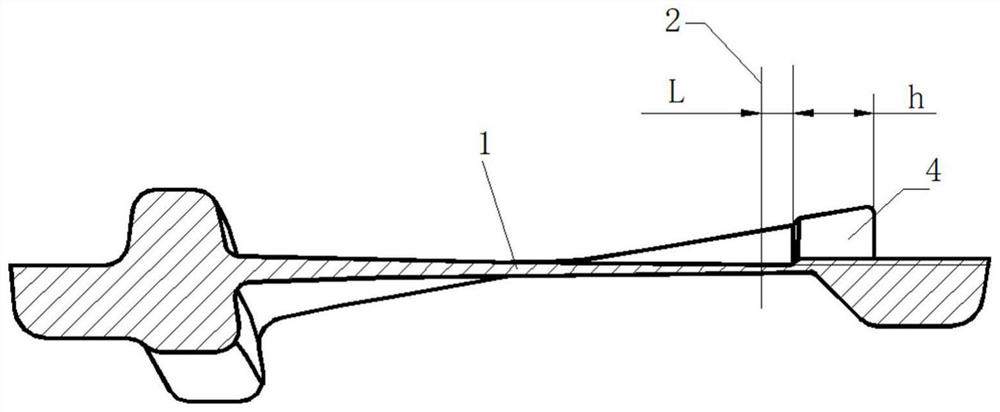

[0031] The dimension h of the reinforcing rib 4 along the length direction of the precision forging body 1 of the rotor blade is 5 mm to 10 mm, and the distance L between one end surface of the reinforcing rib 4 and the plane where the blade tip section 2 is located is not less than 5 mm; Chord length of forging body 1;

[0032] S2, take the created tool plane as the boundary, and use the cross section of the stiffener as the offset surface to perform surface offset to form a stiffener structure model;

[0033] Specifically, use the "split body" function to split the fine forging of the rotor blade into two parts, the rest and the unthickened ribs, to realize the split model of the ...

Embodiment 1

[0036] For precision forgings of rotor blades, the tip of the blade extends along the trend of 10 mm, and the method of the present invention is used to design reinforcing ribs on the back side of the extension of the tip of the blade along the trend. The method of designing ribs is operated by UG three-dimensional modeling software, and the implementation steps are as follows:

[0037] 1) Determine the size of the rib: the length of the rib is 5mm, one end of the rib is aligned with the outermost end of the airfoil, and the other end is kept at a distance of 5mm from the blade tip section; the width dimension includes the entire chord length range; the thickness dimension is selected according to actual needs. mm;

[0038] 2) Create a tool plane: according to the length dimension determined in step 1), create a tool plane within the scope of the extension section;

[0039] 3) Split the three-dimensional shape of the precision forging blade: take the tool plane created in ste...

Embodiment 2

[0043] For precision forgings of rotor blades, the blade tip extends 15 mm along the trend, and the method of the present invention is used to design reinforcing ribs on the back side of the blade tip along the direction of extension. The method of designing ribs is operated by UG three-dimensional modeling software, and the implementation steps are as follows:

[0044]1) Determine the size of the rib: the length is 10mm, one end is aligned with the outermost end of the airfoil, and the other end is kept 5mm away from the blade tip section; the width includes the entire chord length range; the thickness is 5mm according to actual needs;

[0045] 2) Create a tool plane: according to the length dimension determined in step 1), create a tool plane within the scope of the extension section;

[0046] 3) Split the three-dimensional shape of the precision forging blade: take the tool plane created in step 2) as the boundary, use the "split body" function to split the three-dimensiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com