Mounting method, dismounting method and using method of hollow cylinder sample

A technology of hollow cylindrical sample and installation method, which is applied in the field of rock and soil, can solve the problems of increased vacuum negative pressure during consolidation time, disturbance of hollow cylindrical sample, and difficulty in ensuring uniform soil samples, so as to improve the consolidation efficiency and shorten the Sample preparation cycle, easy to compare and analyze the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings, these embodiments are for a more thorough understanding of the present invention and can fully convey the scope of the present disclosure to those skilled in the art. While the drawings show exemplary embodiments of the present disclosure, it is to be understood that the invention is not to be limited to the embodiments set forth herein.

[0044] A method for installing a sample preparation device for a hollow cylindrical sample, comprising the following steps:

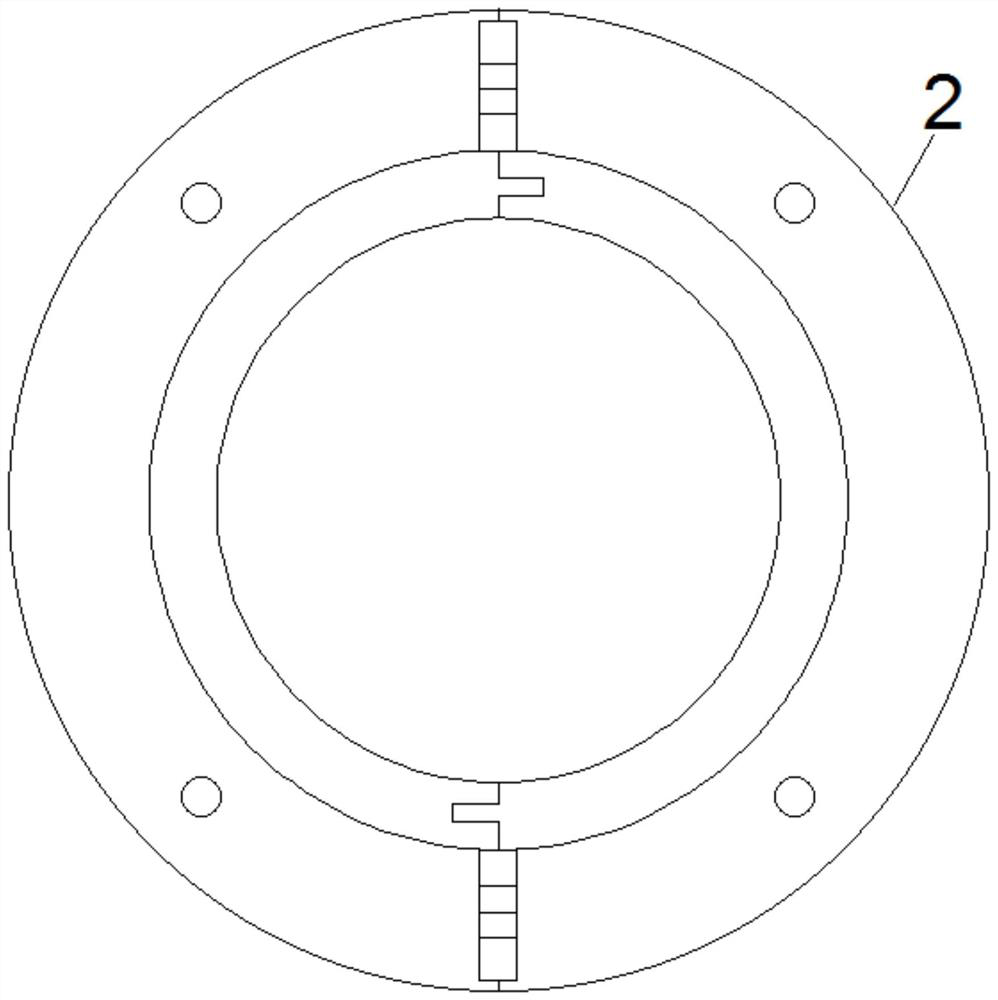

[0045] Step 1, place the drainage chassis 4 on the test frame 7, and keep the drainage chassis 4 level;

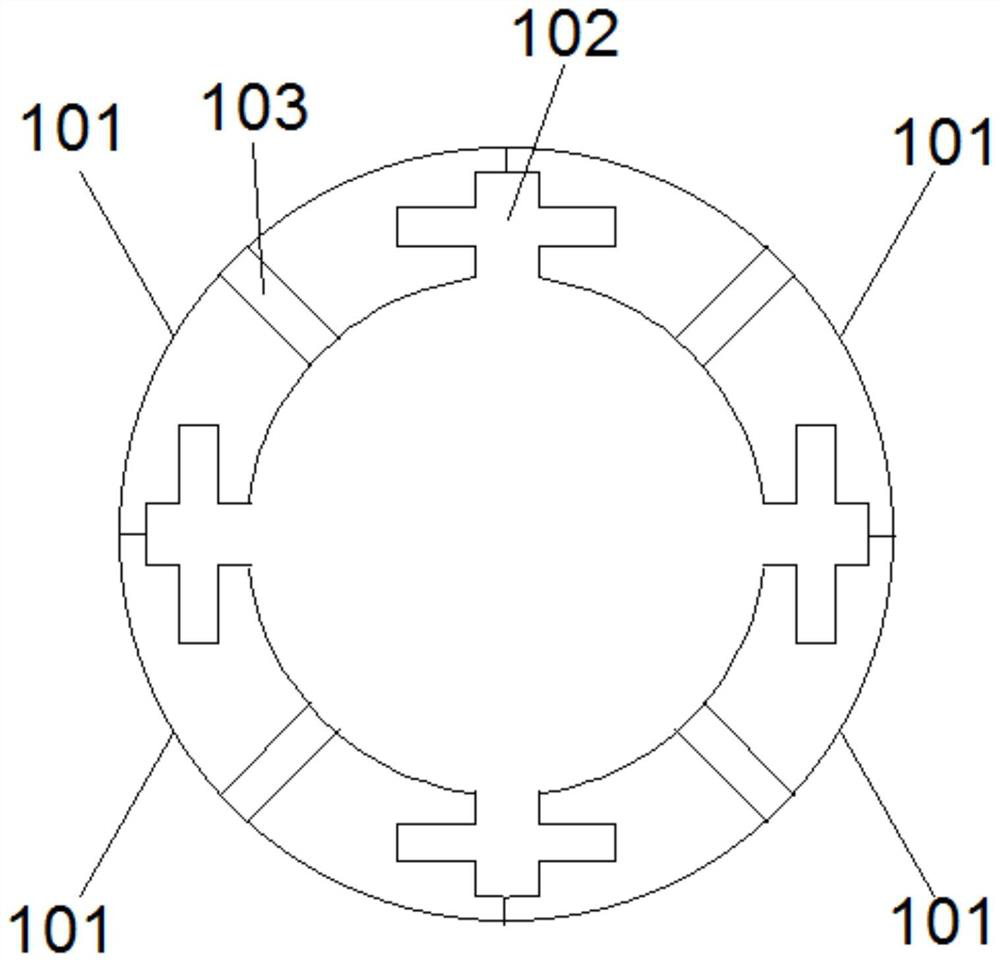

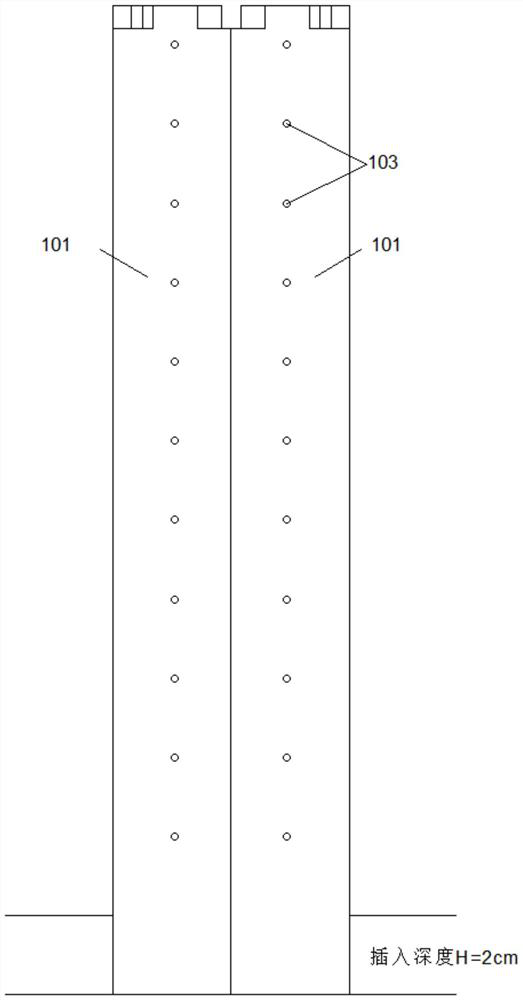

[0046] Step 2. Evenly apply a layer of vacuum sealing grease on the edge of the four-petal inner cylinder assembly 101, align and close the four-petal inner cylinder assembly 101, and insert it into the inner cylinder slot 402 of the drainage chassis 4;

[0047] Step 3. Evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com