Iron-based optically variable pigment as well as preparation method and application thereof

A manufacturing method and pigment technology, applied in optics, optical components, instruments, etc., can solve problems such as increasing manufacturing costs, achieve better secondary peak absorption, make up for the decline in color information, and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

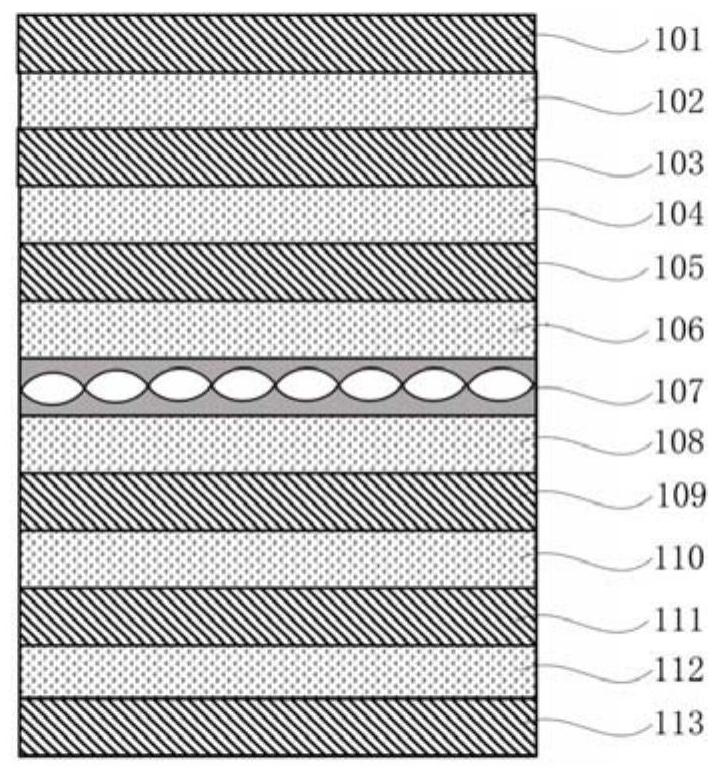

[0039] An iron-based optically variable pigment, comprising: an iron oxide central layer, multiple high-refractive-index layers, and multiple low-refractive-index layers; multiple high-refractive-index layers and multiple low-refractive-index layers are alternately stacked and arranged symmetrically on The upper and lower main surfaces of the iron oxide central layer; multiple cavity structures are arranged inside the iron oxide central layer.

[0040] It should be noted that the material of the high refractive index layer can be at least one of titanium dioxide, hafnium dioxide, tantalum pentoxide, zirconium dioxide, zinc sulfide, or other transparent dielectric materials with a refractive index higher than 2.0; low refractive index The material of the index layer can be one of silicon dioxide, aluminum oxide, magnesium fluoride or a mixture thereof, or any other low-refractive-index material whose refractive index is less than 1.65. The iron oxide center layer may be ferrous...

Embodiment 2

[0045] An iron-based optically variable pigment, see figure 1 , the iron-based optically variable pigment has a red-to-golden optically variable pigment structure. The film layer in the figure is only a schematic diagram of the number of layers. The middle layer is an iron oxide center layer made of ferrous oxide material, and the upper side is set with a silicon dioxide material with a low refractive index. layer, the low refractive index layer of silicon dioxide material is set on the high refractive index layer of titanium dioxide material, so that the high and low refractive index layers are arranged alternately, six layers are arranged on the upper side, and the same six layers are symmetrical on the lower side, and the material and thickness of the same distance on both sides are equal Symmetrical distribution. The specific film layer arrangement is shown in Table 1:

[0046] Table 1: Layer structure and thickness parameters of the di-iron-based optically variable pigme...

Embodiment 3

[0055] An iron-based optically variable pigment, see Figure 4 , the iron-based optically variable pigment is a green-to-blue optically variable pigment structure. The film layer in the figure is only a schematic diagram of the number of layers. The iron oxide center layer prepared by ferric oxide material is used in the middle, and silicon dioxide material is arranged on the upper side. Low-refractive index layer, low-refractive-index material silicon dioxide layer is set on high-refractive-index material titanium dioxide layer, so that high-refractive-index material film layers are arranged alternately, three layers are arranged on the upper side, and the same three layers are symmetrically arranged on the lower side, and the distance on both sides is the same The material and thickness are distributed symmetrically. The specific film layer arrangement is shown in Table 3:

[0056] Table 3: Example three iron-based optical variable pigment layer structure and thickness para...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com