Composite anti-interference trajectory tracking control algorithm for backward process of unmanned rolling machine

A trajectory tracking and unmanned driving technology, which is applied to controllers with specific characteristics, electric controllers, etc. to improve accuracy, enhance anti-interference ability, and improve robustness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A layered hierarchical self-learning compound anti-disturbance trajectory tracking control algorithm for the backward process of an unmanned rolling machine, comprising the following steps:

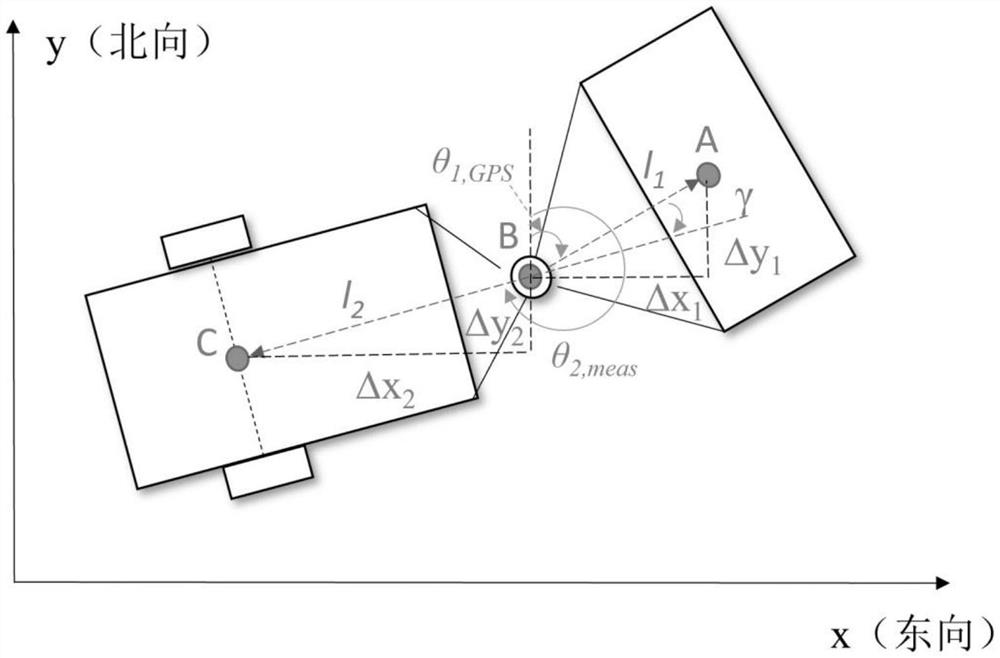

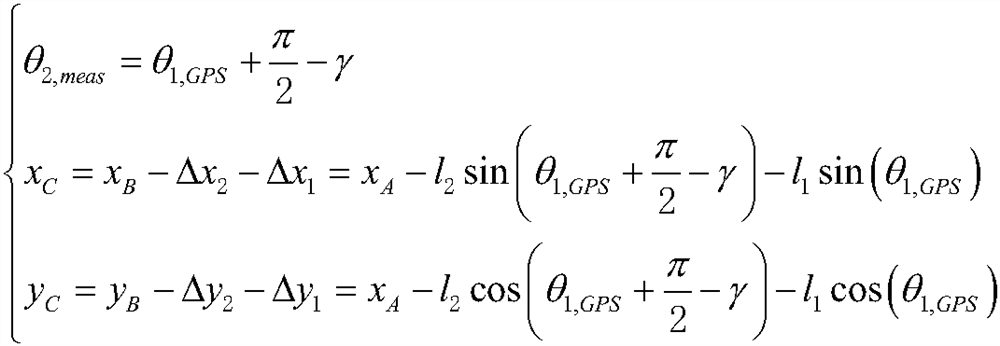

[0047] Step 1, the reconstructor for the position and heading of the rear body, calculates the measured value of the heading angle of the rear body of the vehicle and the position of the rear body, obtains the heading and position of the reconstructed rear body, and then calculates the rolling machine according to the target trajectory of the rolling machine. The actual distance error in the trajectory tracking of the press;

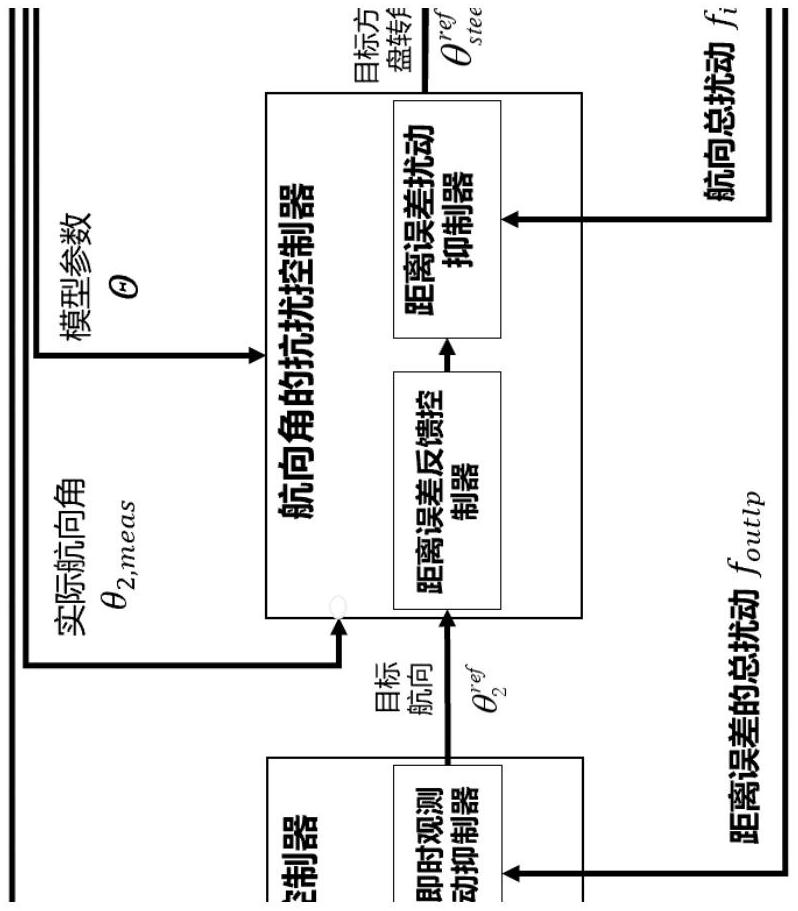

[0048] Step 2, the anti-disturbance controller of the distance error calculates the target heading angle of the rolling machine through the total disturbance of the actual distance error obtained in step 1 and the distance error obtained by the instant disturbance observer, so that the trajectory tracking distance of the rolling machine is error tends to zero...

Embodiment 2

[0052] As a preferred solution, the anti-disturbance controller of the distance error in the step 2 will use the ideal heading angle (θ 2 ) and the actual distance error (e d ) is simplified as a range error dynamic system model, and the deviation between the range error dynamic system model and the actual process is unified as the total disturbance of the range error (f outlp ), put f outlp It is regarded as an extended state in the distance error dynamic system model, that is, the dynamic system model is extended to a dynamic system with a higher order than the original dynamic system model. Using the real-time disturbance observer, using the actual heading angle and actual distance error information, the total disturbance to the distance error (f outlp ) for real-time estimation and real-time compensation in the range error perturbation suppressor. For the system processed by the range error disturbance suppressor, the range error feedback controller is designed, and by ...

Embodiment 3

[0056] As the basis for the development of the control algorithm, the prediction model of the front and rear body angle, heading angle and position of the roller compactor is established first. Although this part of the content is not the content of the present invention, it is still written here for the sake of completeness. In this embodiment, the following simplified heading angle dynamic system model is adopted, but it is not limited to this model. The prediction model of the influence of the steering wheel of the roller compactor on the articulation angle of the front and rear body can be expressed by (1).

[0057]

[0058] Among them, γ is the articulation angle of the front and rear body (unit: radian), is the derivative of the articulation angle of the front and rear body with respect to time, is the target rotation angle of the steering wheel (unit: radian), τ steer is the time constant of the dynamic process of the steering system (unit: second), a is the stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com