Prediction method for regulating and controlling effect of added element on solid solubility of target element and application of prediction method

A technology of adding elements and target elements, which is applied in the field of metal materials, can solve problems such as excessive time and resources, lack of regulation, and cost, and achieve accurate prediction effects, save R&D costs, and reduce blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

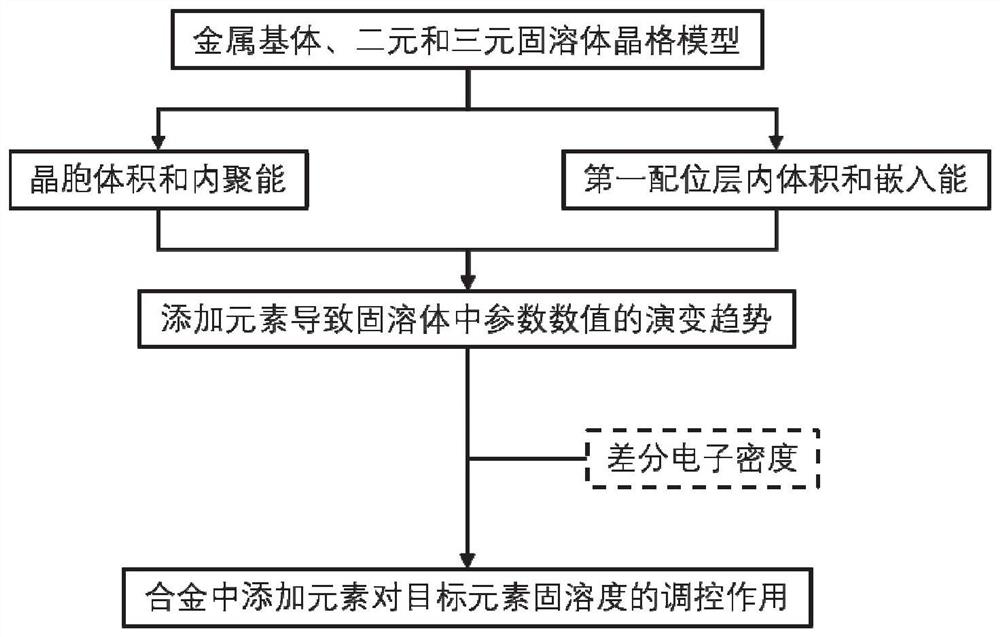

[0079] This embodiment adds an element to the prediction method of the target element solid solubility regulation. figure 1 Indicated. First, a metal matrix, a dual solid solution, a trim sol.stal lattice model is constructed. Secondly, the structural optimization and static computation of the first sexy principle is obtained, and the cell volume and internal concentration energy of the above model and the volume and the embedded energy of the first coordination layer are obtained. According to the above four parameters, it is clear that the addition of elements cause the solid solution from expanding the numerical evolution in the ternary process. If the addition element causes the parameter value in the primary binary solid solution to the metal matrix, the differential electron density in the tri-solid solution is introduced, and the regulation of the addition of elements in the alloy to achieve effective prediction.

Embodiment 2

[0081] Take Ca, Y, Sn, Zn as an example, the regulation of Ca, Y, Sn in the mg alloy is predicted, respectively, and the regulation of Zn solid solutions of Zn is predicted.

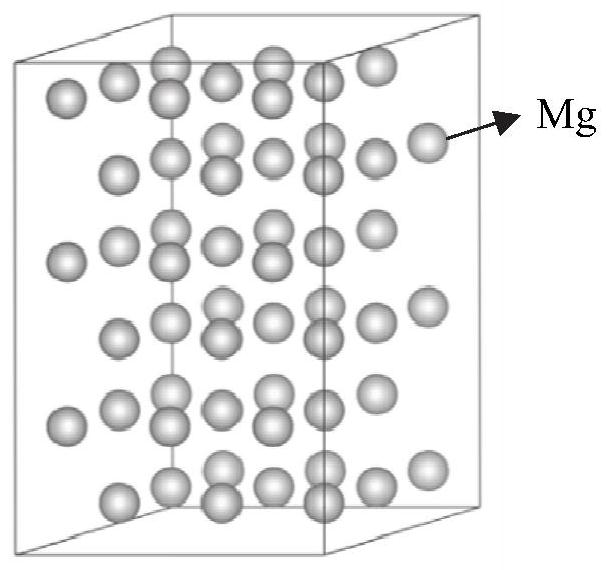

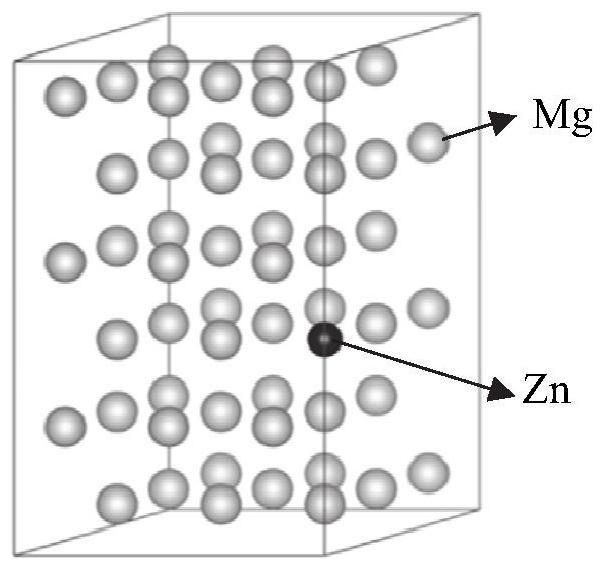

[0082] With Zn as the target element, Ca, Y, Sn is added element, constructs MG matrix, binary mg-Zn solid solution model, target element and the addition of the first coordination layer without shared atoms Mg-Zn-Ca, Mg -Zn-y, mg-Zn-Sn solid solution model Figure 2-4 Indicated.

[0083] Structural optimization is implemented in the above model, and the optimized structure is static, calculate the cell volume and internal strength, such as Figure 5 with Figure 6 Indicated. The calculation parameter is selected: the plane wave truncation can be greater than or equal to 500EV, the Brillin area mesh density is greater than or equal to 9 × 9 × 5. The total energy convergence of the system is less than or equal to 5 × 10 -6 EV / CELL, single atomic force convergence criterion is less than or equal

[0084] Calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com