Integrated power distribution cabinet

An integrated technology for power distribution cabinets, applied in the field of power distribution boxes, can solve problems such as cable crossing confusion, long operation time, and potential safety hazards, and achieve increased heat dissipation, high disassembly and assembly convenience, and improved use safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

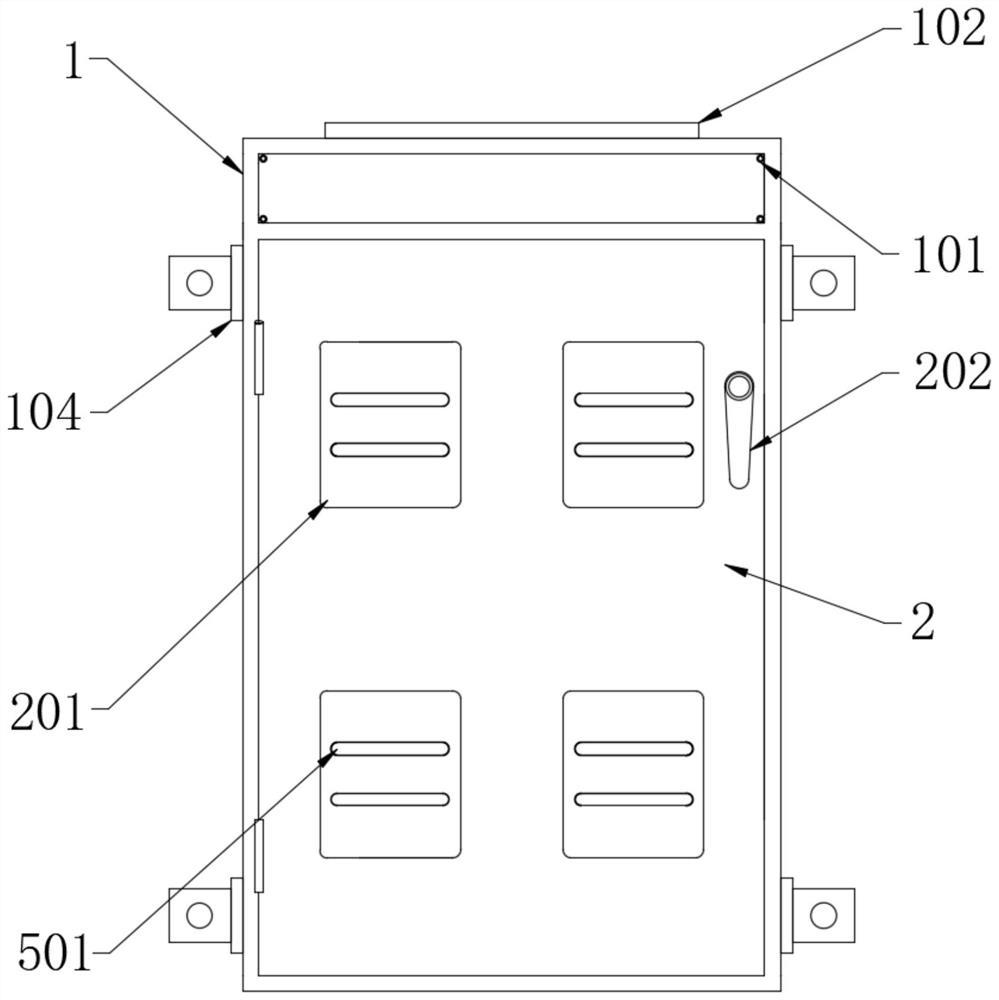

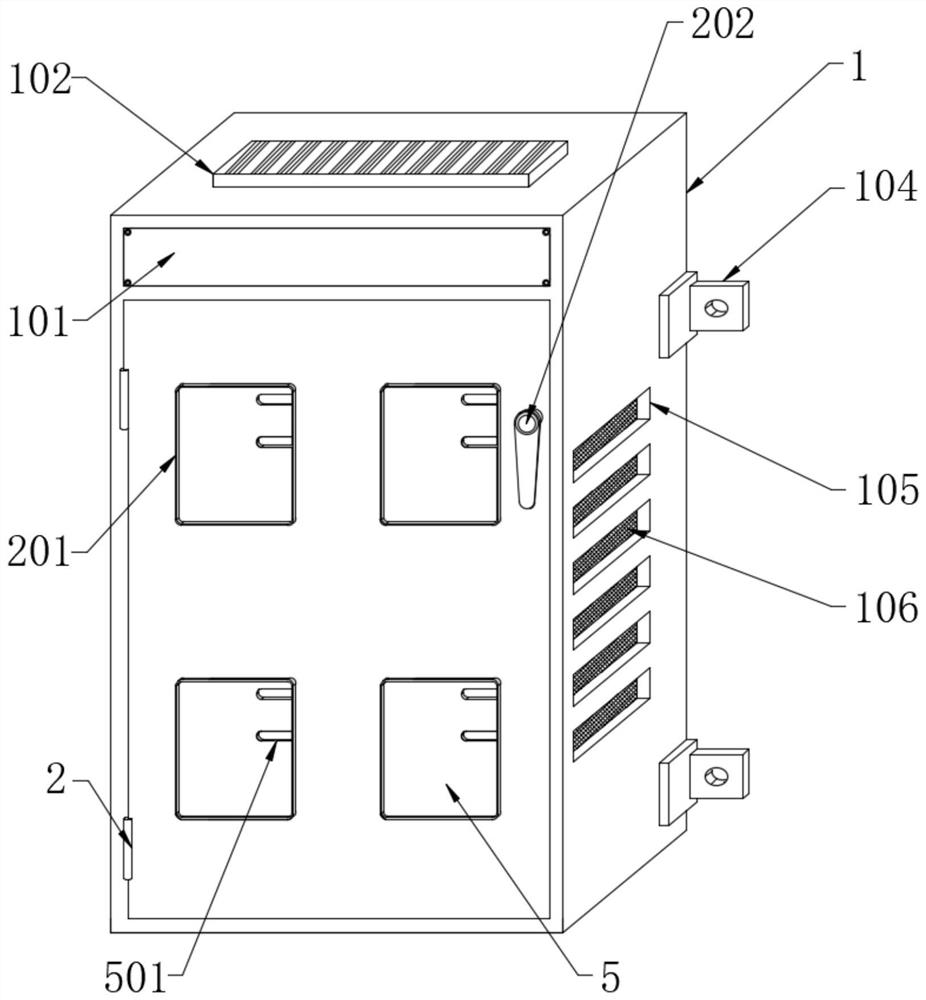

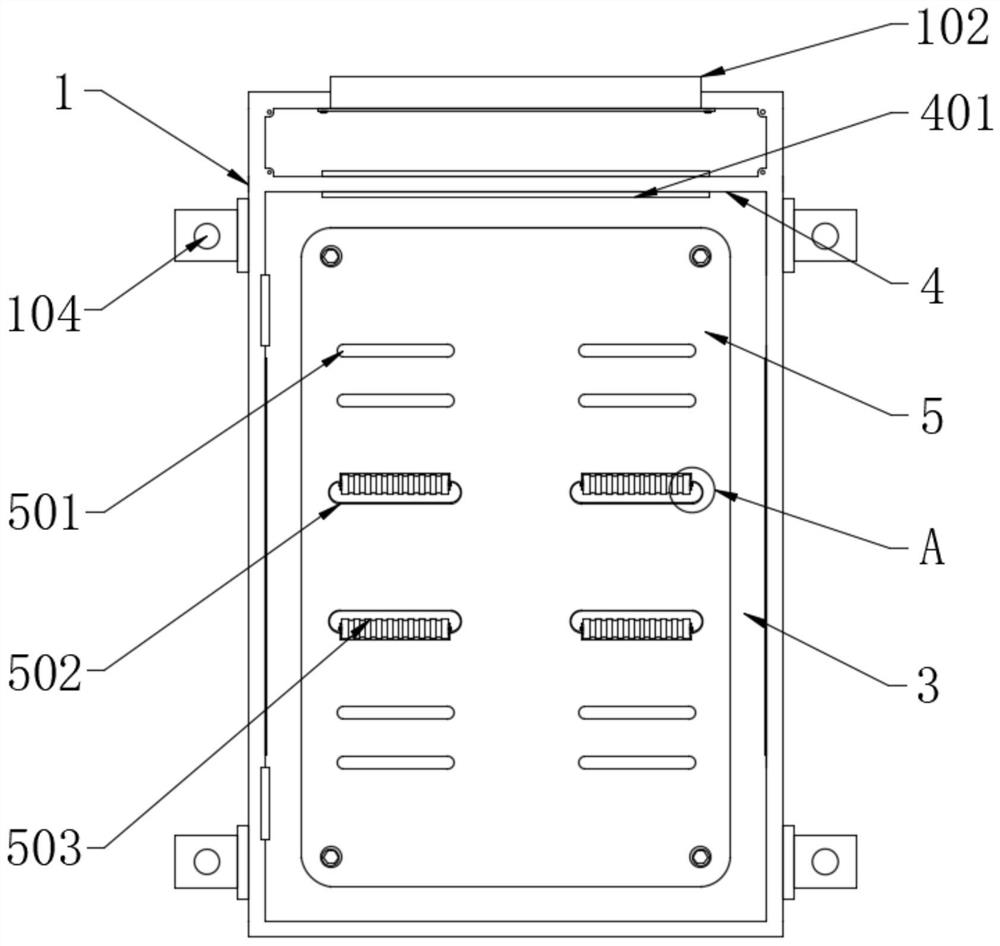

[0033] Please refer to Figure 1 to Figure 10As shown, it shows the specific structure of the preferred embodiment of the present invention, an integrated power distribution cabinet, including a box body 1, a vertical partition 3 and a mounting plate 5, the front side of the box body 1 is installed with The box door 2, and the box body 1 is a hollow cubic structure; the vertical partition 3 is installed inside the box body 1, and a horizontal partition 4 is installed on one side of the box body 1, and the vertical partition 3 cooperates with the horizontal partition The partition board 4 divides the interior of the box body 1 into three independent spaces; the mounting plate 5 is installed on the side of the vertical partition board 3 close to the box door 2, and the connection mode between the installation board 5 and the vertical partition board 3 is a card combined connection.

[0034] Specifically, by opening a plurality of independent spaces in the box body 1, the circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com