Polyisocyanate composition, coating composition and coating base material

A polyisocyanate and composition technology, applied in polyurea/polyurethane coatings, coatings, organic chemistry, etc., can solve the problems of carbon dioxide generation, difficult to disperse, etc., and achieve the effects of excellent hardness and water resistance, appearance and water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0290] Hereinafter, although an Example and a comparative example are given and this invention is demonstrated more concretely, this invention is not limited to a following example unless the summary is exceeded.

[0291] The physical properties and evaluation of the polyisocyanate composition in Examples and Comparative Examples were measured as follows. In addition, unless otherwise stated, "part" and "%" mean "part by mass" and "% by mass".

[0292]

[0293] [Physical property 1] Viscosity

[0294] The viscosity was measured at 25° C. using an E-type viscometer (manufactured by Tokimec, Inc.). Use standard rotor (1°34’×R 2 4). The rotation speed is as follows.

[0295] (Rotating speed)

[0296] 100r.p.m. (less than 128mPa·s)

[0297] 50r.p.m. (128mPa·s above and less than 256mPa·s)

[0298] 20r.p.m. (over 256mPa·s and less than 640mPa·s)

[0299] 10r.p.m. (over 640mPa·s and less than 1280mPa·s)

[0300] 5r.p.m. (1280mPa·s above and less than 2560mPa·s)

[0301] ...

Synthetic example 1-1

[0362] [Synthesis Example 1-1] Synthesis of HES / DPOA

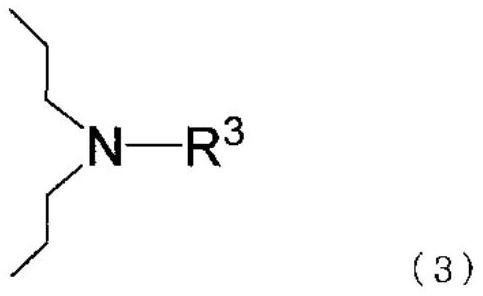

[0363] 1-propanol: 10 mass parts was added to 70 mass % 2-hydroxyethanesulfonic acid (it may abbreviate as "HES" hereafter) aqueous solution: 20 mass parts, it stirred, and obtained the solution. Furthermore, N,N-dipropyl octylamine (hereinafter sometimes abbreviated as "DPOA") was weighed so that the molar equivalent ratio with respect to HES was 1, diluted with 1-propanol of the same mass part, and the obtained The liquid is added dropwise to the preceding solution under stirring. After 1 hour from the start of the dropwise addition, the stirring was stopped, and dehydration and solvent removal were carried out by an evaporator to obtain 2-hydroxyethanesulfonic acid dimethylpropylamine salt (hereinafter sometimes abbreviated as "HES / DPOA") with a solid content of 99.8% by mass. ).

Synthetic example 1-2

[0364] [Synthesis Example 1-2] Synthesis of HES / DMPA

[0365] 2-Hydroxyethanesulfonic acid N,N with a solid content of 99.8% by mass was obtained in the same manner as in Synthesis Example 1-1, except that dimethylpropylamine (hereinafter sometimes abbreviated as "DMPA") was used instead of DPOA. - Dipropyloctylamine salt (hereinafter sometimes abbreviated as "HES / DMPA").

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com