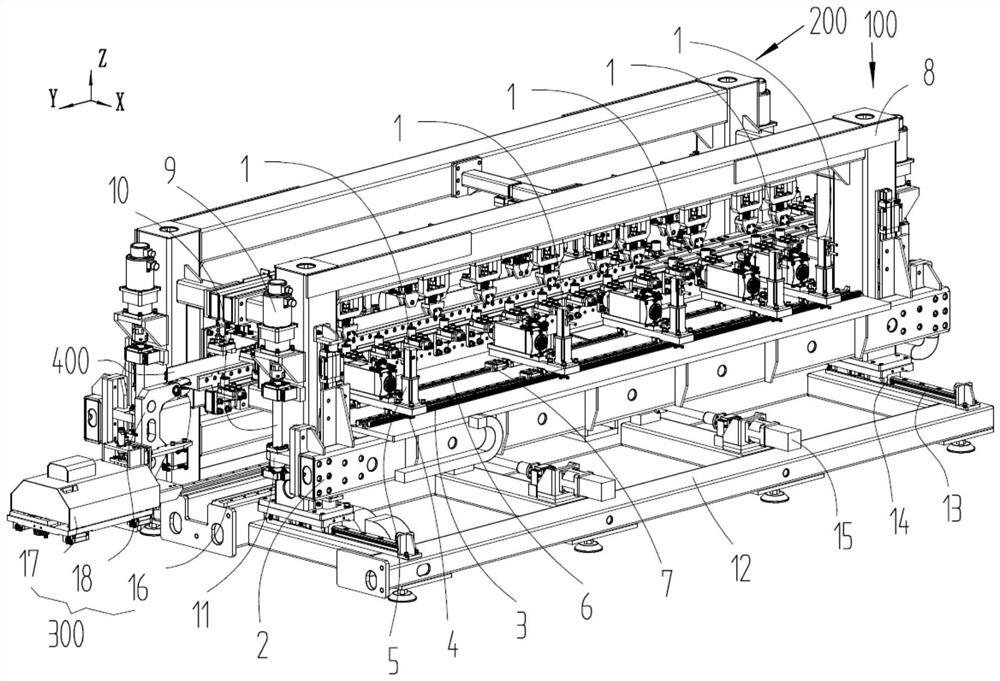

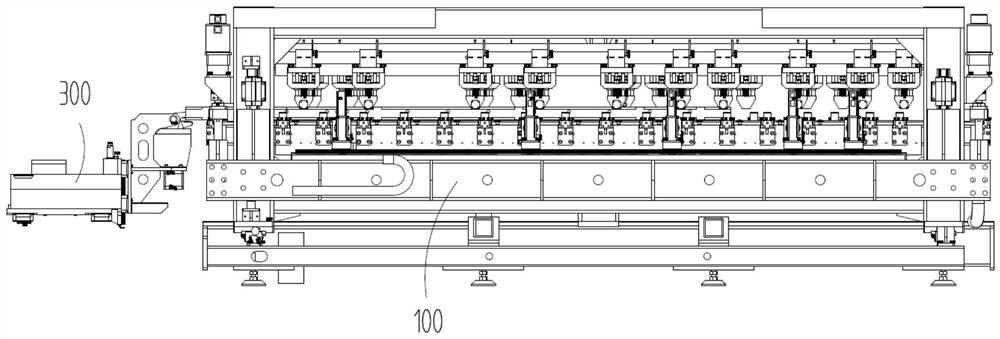

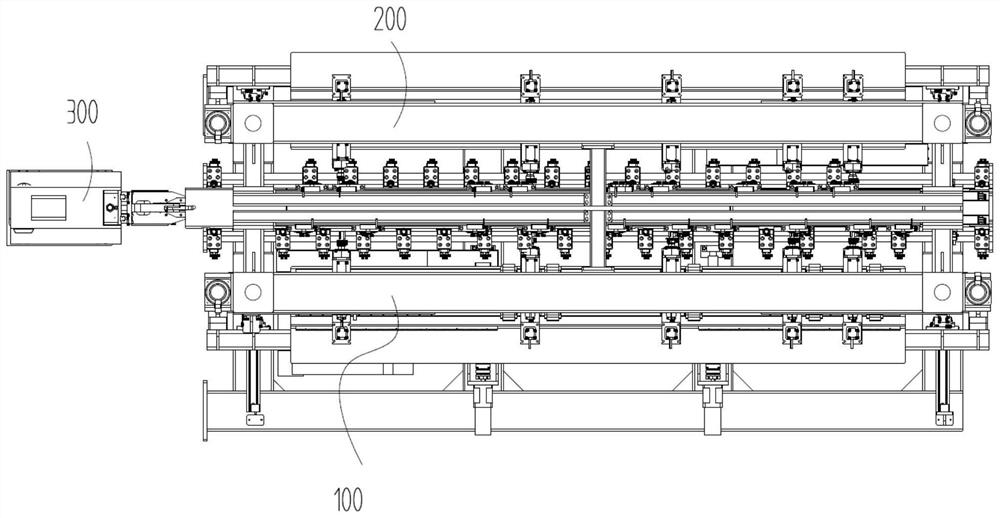

Groove milling machine

A slot milling machine and slot milling technology, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of small aluminum template specifications, difficulty in adapting to automatic production, and non-adjustable distance between milling cutter heads, etc., to meet the requirements of templates The effect of system changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0026] Furthermore, as another embodiment of the present invention, the first Z-direction moving power part includes: a first Z-direction power motor 9 fixed on the first X-axis moving frame 8, a first Z-direction power motor 9 fixed on the first The first lead screw nut 11 on the Z-axis mobile frame 2 and one end are connected to the output shaft of the first Z-direction power motor 9, and the other end is matched with the first transmission lead screw of the first lead screw nut 11 10. The moving direction of the moving pair formed by the first Z-axis mobile frame 2 and the first X-axis mobile frame 8 is the same as that of the first slot milling power head 1 and the first Z-axis mobile frame respectively. 2. The moving direction of the moving pair is vertical. In this embodiment, in the first Z-direction moving power part, a motor is used as power to drive a screw transmission pair including a ball screw to realize movement in the height direction. The screw transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com