Surface polishing device for 3D printing blank and operation method

A 3D printing and surface polishing technology, applied in surface polishing machine tools, devices for fixing grinding wheels, grinding/polishing equipment, etc., can solve the problems of low manual polishing efficiency, limited improvement of surface roughness, poor product consistency, etc. Achieve fast replacement and high efficiency polishing, improve the quality of the final product, good usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

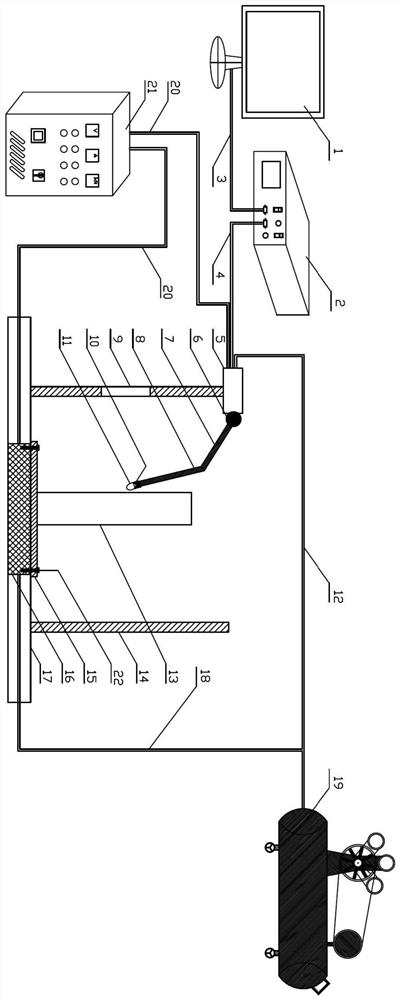

[0036] A surface polishing device for 3D printing blanks, including a control system and a grinding mechanism;

[0037] Described grinding mechanism comprises working platform 17 and the protective partition 14 that is symmetrically installed on both sides of the upper end of working platform 17, and the upper end of one of the protective partition 14 is equipped with fixed arm 5, and the other end of fixed arm 5 is connected by rotation. The unit 6 is connected with a movable telescopic arm 7 with a built-in telescopic structure and a mechanical transmission system, and the end of the movable telescopic arm 7 is equipped with a movable arm 8, and the other end of the movable arm 8 is provided with a grinding head mounting seat 10, and the grinding head mounting seat 10 A grinding head 11 is detachably installed; an observation window 9 for monitoring printing conditions is embedded on the protective partition 14 near the fixed arm 5;

[0038] The fixed arm 5 is also connected...

Embodiment 2

[0043] The present invention also provides a method for operating a 3D printing workpiece surface polishing device, comprising the following steps:

[0044] S1. Fix the 3D printing blank 13 on the blank mounting seat 16 through the clamping tool 15;

[0045] S2. Import the three-dimensional digital model of the 3D printing blank 13 into the computer 1, select the part to be polished on the three-dimensional digital model, and transmit the information to the PLC control system after data conversion by the data processor 2;

[0046] S3. The polishing index is set by the main control box 21, and the information is transmitted to the PLC control system according to the set data, so that the linkage system can be linked according to the trajectory set by the program, so as to realize the polishing of the 3D printing blank 13;

[0047] The formula for calculating the polishing coefficient is shown in Equation 1,

[0048] W a =F m / (σ b ·S) (1)

[0049] In the formula: Wa-polish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com