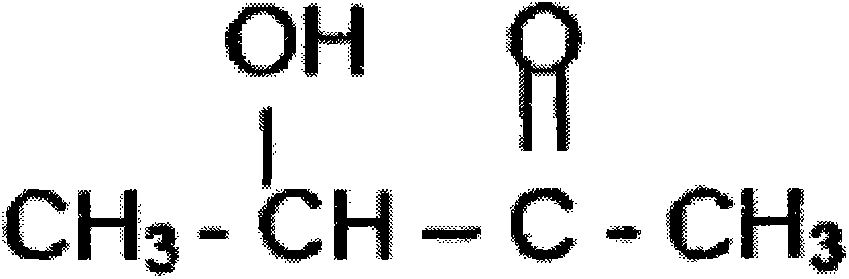

A kind of purification method of 3-hydroxybutanone

A technology of hydroxybutanone and purification method, which is applied in the separation/purification of carbonyl compounds, organic chemistry, etc., and can solve the problem of no concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 13

[0015] A kind of purification method of embodiment 13-hydroxybutanone, carry out successively according to the following steps:

[0016] 1. Distillation under reduced pressure of fermentation broth: Centrifuge 70L of fermentation broth containing 56.5g / L of 3-hydroxybutanone to remove bacteria, distill under reduced pressure at 90°C, recover the condensate, and measure the content of 3-hydroxybutanone to be 58.1 g / L.

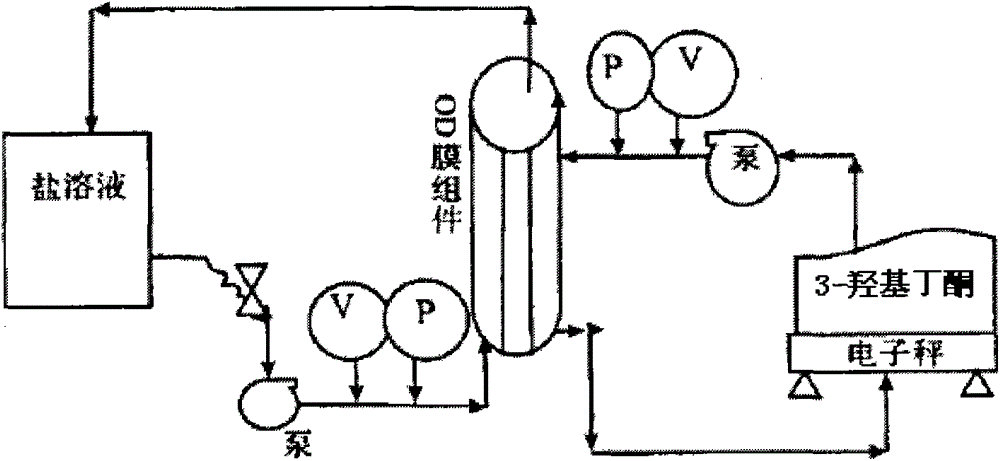

[0017] 2. Osmotic distillation (OD) concentration: polyethylene hollow fiber membrane, CaCl 2 As extractant (salt solution), with CaCl 2 Solution - distilled water for saline solution system, CaCl 2 The concentration is 55% (W / W), the temperature of the salt solution and 3-hydroxybutanone distillate is 50° C., and the feed rate is 70 L / h.

[0018] After vacuum distillation and osmotic distillation, 58.6 L of distillate was finally obtained, the content of 3-hydroxybutanone was 62.3 g / L, the purification yield was 92.3%, and the product purity was 99.2%.

Embodiment 23

[0019] A kind of purification method of embodiment 23-hydroxybutanone, carry out successively according to the following steps:

[0020] 1. Distillation under reduced pressure of fermentation broth: Centrifuge 70L of fermentation broth containing 56.2g / L of 3-hydroxybutanone to remove bacteria, distill under reduced pressure at 80°C, recover the condensate, and measure the content of 3-hydroxybutanone to be 57.5 g / L.

[0021] 2. Osmotic distillation (OD) concentration: polyethylene hollow fiber membrane is used, NaCl is used as the extractant (salt solution), NaCl solution-distilled water is the salt solution system, the concentration of NaCl is 20% (W / W), the salt solution and The temperature of the 3-hydroxybutanone distillate was 55° C., and the feed rate was 60 L / h.

[0022] After vacuum distillation and osmotic distillation, 59.3 L of distillate was finally obtained, the content of 3-hydroxybutanone was 61.4 g / L, the purification yield was 92.6%, and the product purity w...

Embodiment 33

[0023] A kind of purification method of embodiment 33-hydroxybutanone, carry out successively according to the following steps:

[0024] 1. Distillation of fermentation broth under reduced pressure: Centrifuge 70L of fermentation broth containing 56.8g / L of 3-hydroxybutanone to remove bacteria, distill under reduced pressure at 90°C, recover the condensate, and measure the content of 3-hydroxybutanone to be 58.5 g / L.

[0025] 2. Osmotic distillation (OD) concentration: use polytetrafluoroethylene hollow fiber membrane, CaCl 2 As extractant (salt solution), with CaCl 2 Solution - distilled water for saline solution system, CaCl 2 The concentration is 50% (W / W), the temperature of the salt solution and 3-hydroxybutanone distillate is 45° C., and the feed rate is 65 L / h.

[0026] After vacuum distillation and osmotic distillation, 57.9 L of distillate was finally obtained, the content of 3-hydroxybutanone was 62.2 g / L, the purification yield was 90.6%, and the product purity w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com