Production method of phthalocyanine blue anti-flooding dispersant

A dispersant and anti-floating technology, applied in the direction of organic dyes, pigment pastes, etc., can solve the problems of poor stability and poor compatibility of phthalocyanine blue paste, and achieve low equipment requirements, good compatibility and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

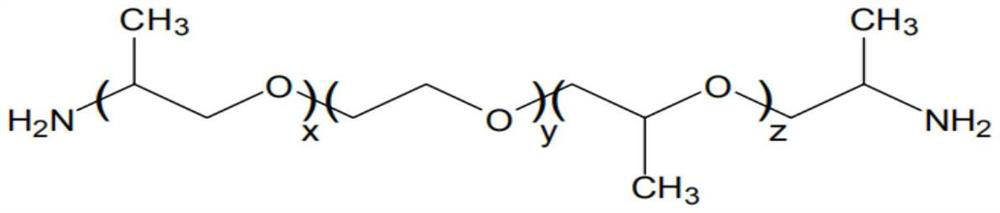

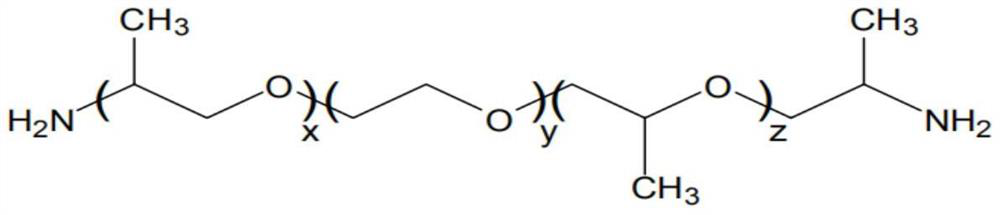

Image

Examples

Embodiment 1

[0018] In this example, 295Kg of tall oleic acid, 100Kg of oleic acid, 440Kg of polyetheramine D400, and 450Kg of wetting agent PPG200 were put into a 200L reactor; the temperature was raised to 120-150°C, and the reaction was kept for 3-5 hours; the temperature was lowered to below 45°C , that is, the finished product of phthalocyanine blue anti-floating dispersant.

Embodiment 2

[0020] In this example, 100Kg of linoleic acid, 220Kg of abietic acid, 85Kg of oleic acid, 150Kg of polyetheramine D230, and 280Kg of ED2000 were put into a 200L reactor; the temperature was raised to 115-145°C, and the reaction was kept for 3-5 hours; the temperature was lowered to 45°C The following is the finished product of phthalocyanine blue anti-floating dispersant

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com