Super-bright colored aluminum pigment and preparation method thereof

An aluminum pigment, ultra-bright technology, applied in the direction of fibrous fillers, dyed polymer organic compounds, etc., to achieve good solvent and corrosion resistance, good white brightness, and strong adjustability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

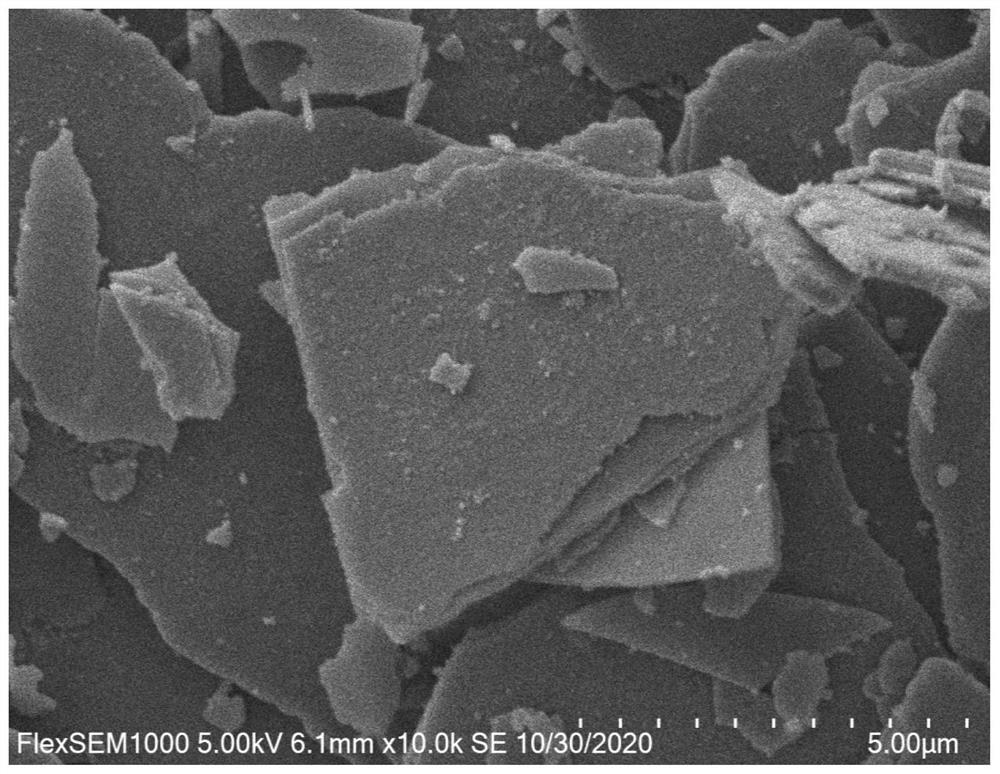

Image

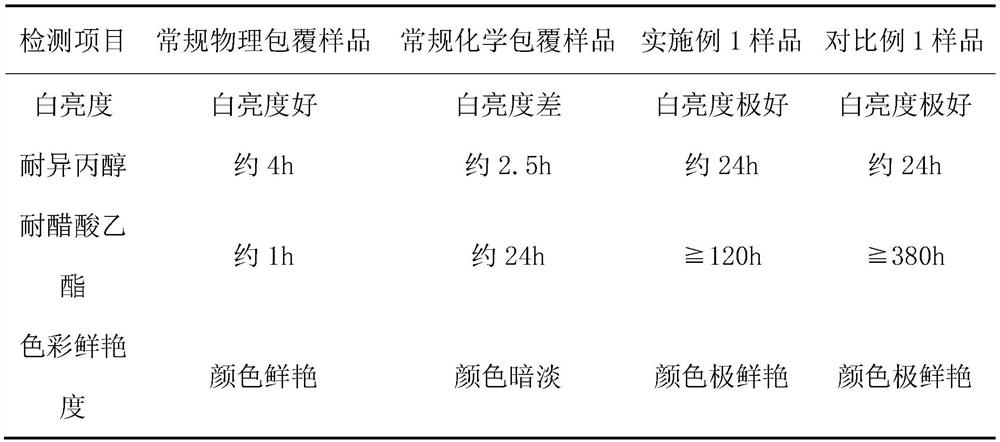

Examples

Embodiment 1

[0028] A preparation method of a super-bright color aluminum pigment, the steps comprising:

[0029] Step 1: Prepare a colored thermosetting polymer coating for use; the colored thermosetting polymer coating is a two-component coating prepared by acrylic resin, curing agent, color paste, solvent and additives.

[0030] Step 2: select the separation layer resin emulsion, and print it on the surface of the PET film, and dry to obtain the film layer A; the separation layer resin emulsion is selected from nitro resin, and the separation layer resin emulsion is dissolved by a solvent before printing, and Solvent selects butyl acetate for use, and the content (mass) of separation layer resin emulsion in solvent is 2%; Described separation layer resin emulsion is printed by coating machine, and the drying temperature during printing is 110 ℃, and printing speed is 110m / min, the printing weight is 1.0g / m 2 Ww.

[0031] Step 3: Print the colored thermosetting polymer coating on one ...

Embodiment 2

[0037] A preparation method of a super-bright color aluminum pigment, the steps comprising:

[0038] Step 1: Prepare a colored thermosetting polymer coating for use; the colored thermosetting polymer coating is a two-component coating prepared by acrylic resin, curing agent, color paste, solvent and additives.

[0039] Step 2: select the separation layer resin emulsion, and print it on the surface of the PET film, and dry to obtain the film layer A; the separation layer resin emulsion is selected from polyvinylpyrrolidone resin, and the separation layer resin emulsion is dissolved by a solvent before printing, And solvent selects ethyl acetate for use, the content (mass) of separating layer resin emulsion in solvent is 3%; Described separating layer resin emulsion is printed by coating machine, and the drying temperature during printing is 130 ℃, and printing speed is 130m / min, the printing volume is 2.0g / m 2 Ww.

[0040] Step 3: Print the colored thermosetting polymer coat...

Embodiment 3

[0046] A preparation method of a super-bright color aluminum pigment, the steps comprising:

[0047] Step 1: Prepare a colored thermosetting polymer coating for use; the colored thermosetting polymer coating is a two-component coating prepared by acrylic resin, curing agent, color paste, solvent and additives.

[0048] Step 2: select the separation layer resin emulsion, and print it on the surface of the PET film, and dry to obtain the film layer A; the separation layer resin emulsion is selected from polyvinylpyrrolidone resin, and the separation layer resin emulsion is dissolved by a solvent before printing, And solvent selects propylene glycol methyl ether acetate and ethanol (volume 1:1), and the content (mass) of separating layer resin emulsion in solvent is 5%; Described separating layer resin emulsion is printed by coating machine, and when printing The drying temperature is 150°C, the printing speed is 160m / min, and the printing weight is 3.0g / m 2 Ww.

[0049] Step 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com