Light-absorbing and heating functional fiber and spinning process thereof as well as fabric

A functional fiber, light absorption and heating technology, applied in textile, melt spinning, textiles and paper making, etc., can solve the problems of poor light absorption and heat generation efficiency, reduce pollution, reduce water resource consumption and energy consumption, good light absorption The effect of the heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

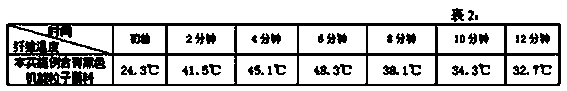

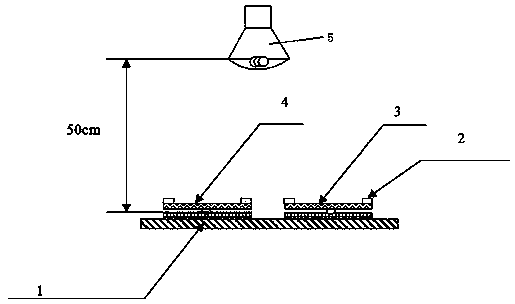

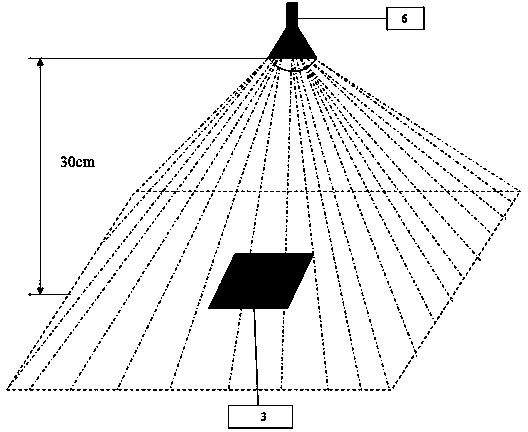

Embodiment 1

[0015] A light-absorbing and heat-generating functional fiber, which is made of 95 parts by weight of polyester chips, 1 part by weight of carbon black particles for pigments, and 4 parts by weight of masterbatches, which are mixed and spun It is processed, and its specific spinning process is as follows: polyester chips, masterbatches and carbon black particles for pigments are mixed according to the above weight ratio after drying, the drying temperature is 180 ° C, and the polyester chips are controlled after drying. The moisture content is 3.0×10 -5 Next, the above-mentioned dried mixture was melted at a temperature of 300° C. and then spun, and the spinning speed was controlled at 3100 m / min. The light-absorbing and heat-generating functional fibers are cut, spun, weaved, dropped into water and shaped in sequence to make light-absorbing and heat-generating functional fabrics. Test the heat absorption performance of this fabric and ordinary fiber fabrics with heat storage...

Embodiment 2

[0021] A light-absorbing and heat-generating functional fiber, which is made of 90 parts by weight of polyester chips, 1 part by weight of carbon black particles for pigments, and 9 parts by weight of masterbatches, which are mixed and then spun It is processed, and its specific spinning process is as follows: polyester chips, color masterbatch and carbon black particles for pigments are mixed according to the above weight ratio after drying, the drying temperature is 165 ° C, and the polyester chips are controlled after drying. The moisture content is 3.0×10 -5 Next, the above-mentioned dried mixture was melted at a temperature of 290° C. and then spun, and the spinning speed was controlled at 3050 m / min. The light-absorbing and heat-generating functional fibers are cut, spun, weaved, dropped into water and shaped in sequence to make light-absorbing and heat-generating functional fabrics. Test the heat absorption performance of this fabric and ordinary fiber fabrics with hea...

Embodiment 3

[0027] A light-absorbing and heat-generating functional fiber, which is made of 98 parts by weight of polyester chips and 2 parts by weight of carbon black particles for pigments, which are mixed and processed by spinning. The specific spinning process The process is as follows: the polyester chips, color masterbatches and carbon black particles for pigments are mixed according to the above weight ratio after drying, the drying temperature is 173°C, and the water content of the polyester chips is controlled to be 3.0×10 after drying. -5 Next, the above-mentioned dried mixture was melted at a temperature of 280° C. and then spun, and the spinning speed was controlled at 3100 m / min. The light-absorbing and heat-generating functional fibers are cut, spun, weaved, dropped into water and shaped in sequence to make light-absorbing and heat-generating functional fabrics. Test the heat absorption performance of this fabric and ordinary fiber fabrics with heat storage function processe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com