A photothermal composite material with functions of light absorption, heat generation and heat storage and preparation method thereof

A technology of light absorption and heating, composite materials, applied in heat exchange materials, chemical instruments and methods, other chemical processes, etc., can solve the problems of low solar energy utilization efficiency, low heat storage efficiency, large heat loss, etc., and achieve good light absorption and heating effect. , High heat storage density, the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

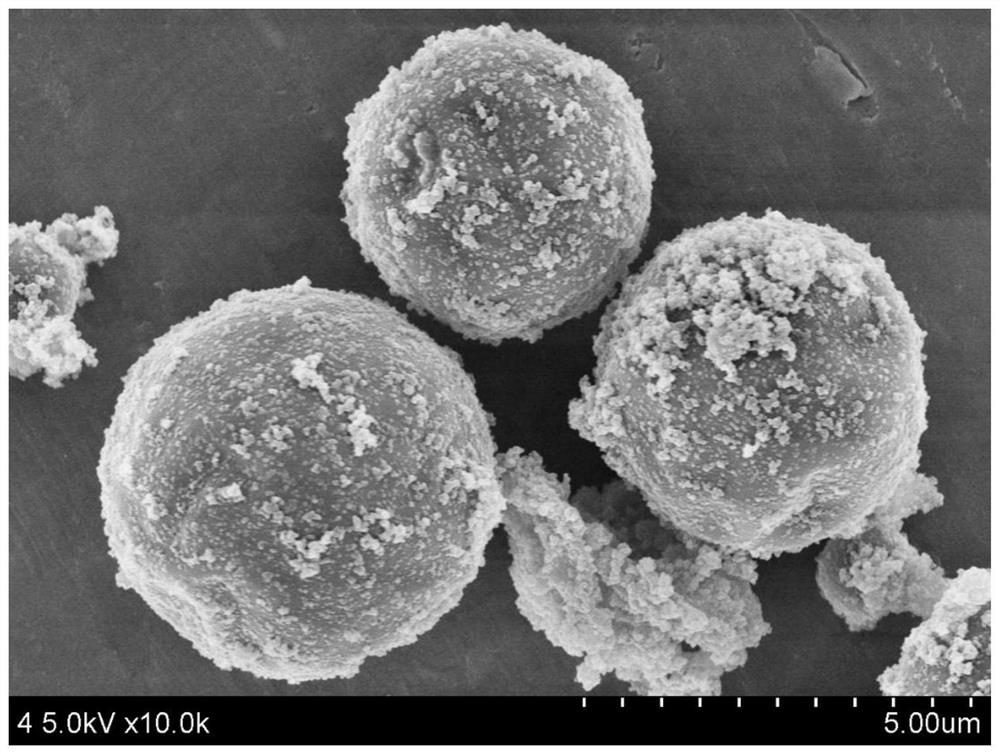

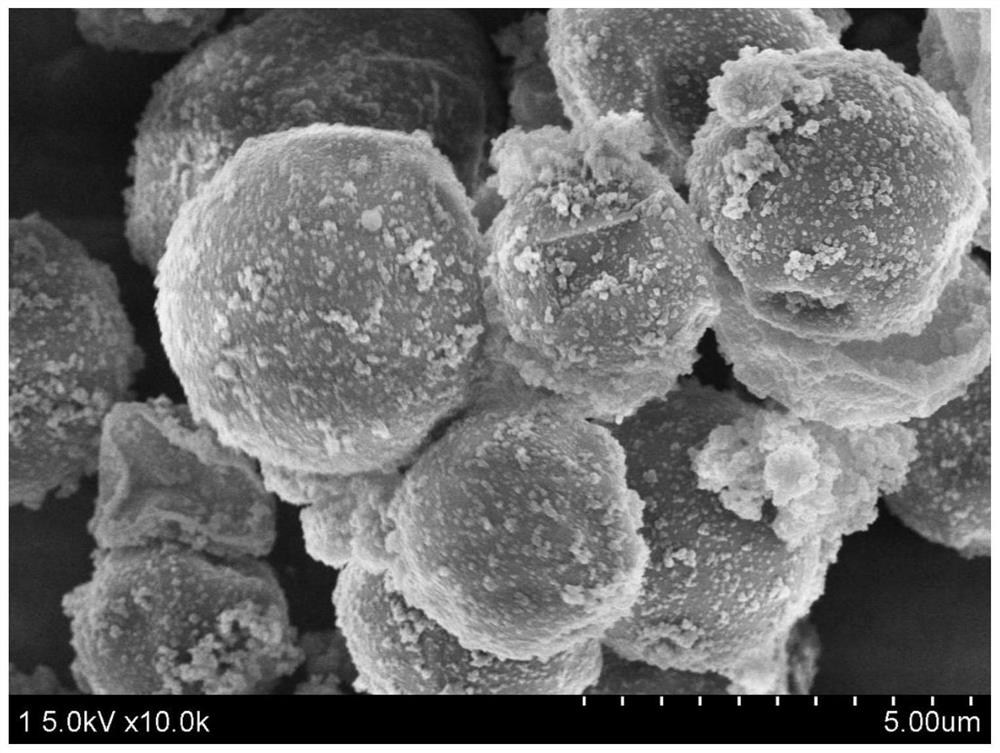

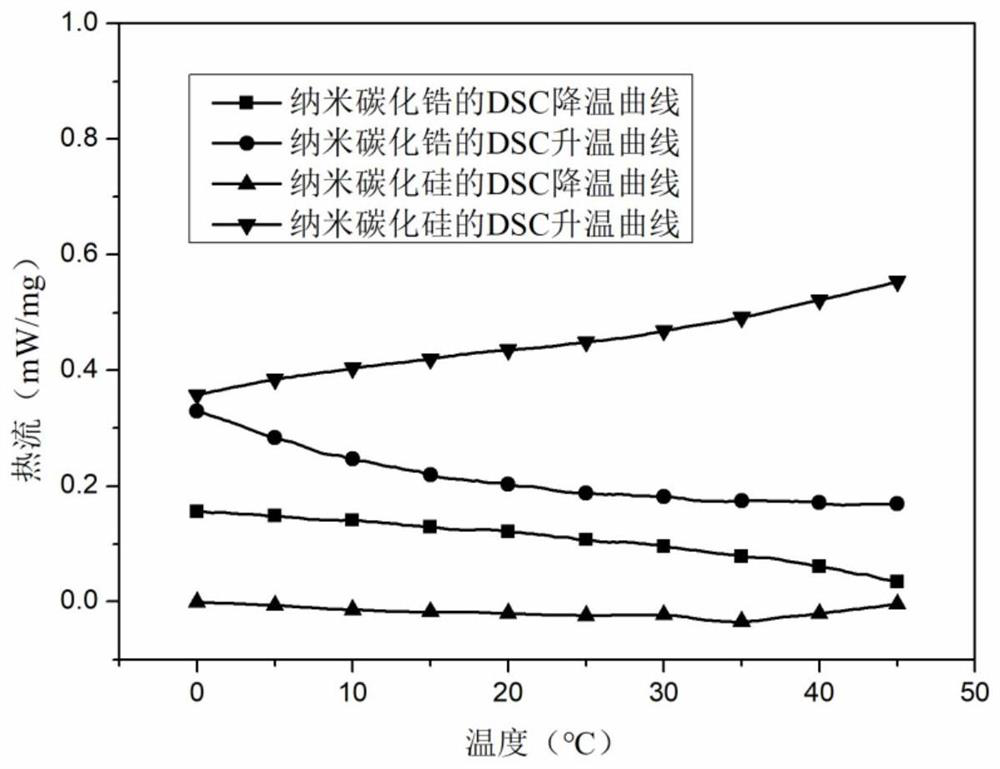

[0041] The nano-light-absorbing heat-generating material and the organic phase-change material selected in this example are nano-zirconium carbide and n-dodecanol respectively, and the preparation steps are as follows:

[0042] (1) Preparation of nano zirconium carbide dispersion

[0043] Dissolve 1.00 g of polyvinylpyrrolidone in 99.00 g of deionized water, adjust the pH value of the system to about 9.0 with 0.1 mol / L sodium hydroxide, and obtain an aqueous solution of polyvinylpyrrolidone with a mass concentration of 1%. Take 5.26g of nanometer zirconium carbide and add it into the above solution, stir it magnetically for 30 minutes and then ultrasonically treat it for 50 minutes, so as to obtain a dispersion of nanometer zirconium carbide with a mass concentration of 5%.

[0044] (2) Preparation of photothermal heat storage emulsion

[0045] 10.00 g of n-dodecanol and 2.00 g of isophorone diisocyanate were mixed respectively, and stirred evenly in a water bath at 40° C. to...

Embodiment 2

[0049] The nano-light-absorbing heat-generating material and the organic phase-change material selected in this example are nano-silicon carbide and n-hexadecane, respectively, and the preparation steps are as follows:

[0050] (1) Preparation of nano-silicon carbide dispersion

[0051] Dissolve 1.00 g of polyvinylpyrrolidone in 99.00 g of deionized water, adjust the pH value of the system to about 9.0 with 0.1 mol / L sodium hydroxide, and obtain an aqueous solution of polyvinylpyrrolidone with a mass concentration of 1%. Take 5.26g of nano-silicon carbide and add it to the above solution, stir it magnetically for 30 minutes and then ultrasonically treat it for 70 minutes, so as to obtain a nano-silicon carbide dispersion with a mass concentration of 5%.

[0052] (2) Preparation of photothermal heat storage emulsion

[0053] 10.00 g of n-hexadecane and 2.00 g of isophorone diisocyanate were mixed respectively, and stirred evenly in a water bath at 40° C. to obtain an oil phase...

Embodiment 3

[0057] The nano-light-absorbing heat-generating material and the organic phase-change material selected in this example are nano-zirconium carbide and n-octadecane respectively, and the preparation steps are as follows:

[0058] (1) Preparation of nano zirconium carbide dispersion

[0059] Dissolve 1.00 g of polyvinylpyrrolidone in 94.00 g of deionized water, adjust the pH value of the system to about 9.0 with 0.1 mol / L sodium hydroxide, and obtain an aqueous solution of polyvinylpyrrolidone with a mass concentration of 1.05%. 5.00 g of nano zirconium carbide was added to the above solution, magnetically stirred for 30 min and then ultrasonically treated for 60 min to obtain a nano zirconium carbide dispersion with a mass concentration of 5%.

[0060] (2) Preparation of photothermal heat storage emulsion

[0061] 14.00 g of n-octadecane and 2.00 g of isophorone diisocyanate were mixed respectively, and stirred evenly in a water bath at 40° C. to obtain an oil phase. The sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com