Galvanized steel strand for corrosion-resistant maritime work optical cable and preparation process of galvanized steel strand

A technology of galvanized steel strand and preparation process, applied in hot-dip plating process, metal material coating process, optics, etc. Corrosion performance, the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

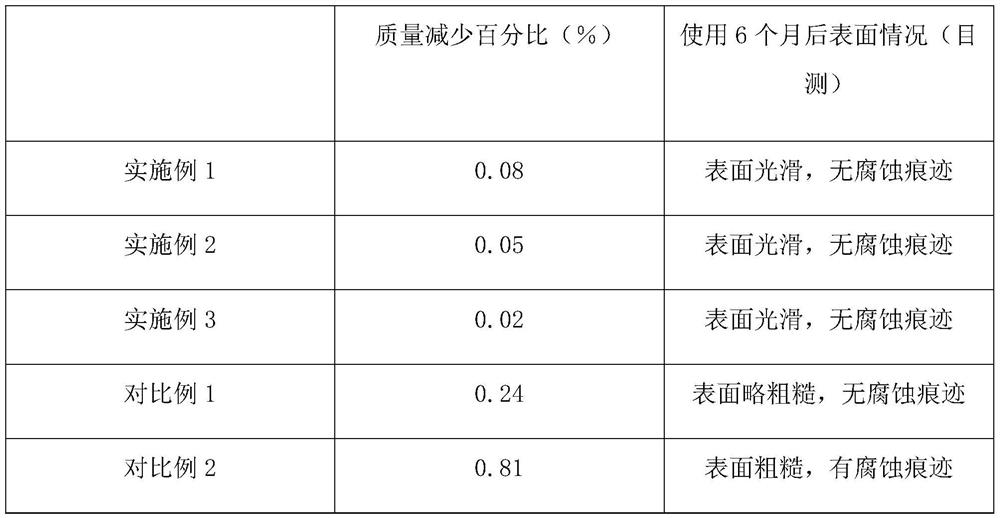

Examples

Embodiment 1

[0064] A process for preparing galvanized steel strands for corrosion-resistant marine optical cables, comprising the following steps:

[0065] S1: Pretreatment the wire rod with pickling, water washing and phosphorous washing;

[0066] S2: drawing the pretreated wire rod once to obtain a drawn steel wire;

[0067] S3: Perform lead washing, water washing, pickling, water washing, alkali washing, and water washing on the primary drawn steel wire, then hot-dip aluminum, and perform secondary drawing to obtain secondary drawn steel wire;

[0068] S4: Coating the secondary drawn steel wire with an adhesive layer and hot-dip galvanizing to obtain a hot-dip galvanized steel wire;

[0069] S5: Twisting the steel wire to obtain a pretreated steel strand;

[0070] S6: Stabilizing the pretreated steel strand to obtain a galvanized steel strand.

[0071] Among them, S1:

[0072] Rinse the wire rod with water after pickling, and then place it in a phosphating tank for phosphating;

...

Embodiment 2

[0093] A process for preparing galvanized steel strands for corrosion-resistant marine optical cables, comprising the following steps:

[0094] S1: Pretreatment the wire rod with pickling, water washing and phosphorous washing;

[0095] S2: drawing the pretreated wire rod once to obtain a drawn steel wire;

[0096] S3: Perform lead washing, water washing, pickling, water washing, alkali washing, and water washing on the primary drawn steel wire, then hot-dip aluminum, and perform secondary drawing to obtain secondary drawn steel wire;

[0097] S4: Coating the secondary drawn steel wire with an adhesive layer and hot-dip galvanizing to obtain a hot-dip galvanized steel wire;

[0098] S5: Twisting the steel wire to obtain a pretreated steel strand;

[0099] S6: Stabilizing the pretreated steel strand to obtain a galvanized steel strand.

[0100] Among them, S1:

[0101] Rinse the wire rod with water after pickling, and then place it in a phosphating tank for phosphating;

...

Embodiment 3

[0122] A process for preparing galvanized steel strands for corrosion-resistant marine optical cables, comprising the following steps:

[0123] S1: Pretreatment the wire rod with pickling, water washing and phosphorous washing;

[0124] S2: drawing the pretreated wire rod once to obtain a drawn steel wire;

[0125] S3: Perform lead washing, water washing, pickling, water washing, alkali washing, and water washing on the primary drawn steel wire, then hot-dip aluminum, and perform secondary drawing to obtain secondary drawn steel wire;

[0126] S4: Coating the secondary drawn steel wire with an adhesive layer and hot-dip galvanizing to obtain a hot-dip galvanized steel wire;

[0127] S5: Twisting the steel wire to obtain a pretreated steel strand;

[0128] S6: Stabilizing the pretreated steel strand to obtain a galvanized steel strand.

[0129] Among them, S1:

[0130] Rinse the wire rod with water after pickling, and then place it in a phosphating tank for phosphating;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com