Novel low-temperature liquid jacket finned tube type vaporization device

A low-temperature liquid, finned tube technology, applied in the direction of tubular elements, heat exchanger types, fixed tubular conduit components, etc., can solve the problems of not being able to truly reflect the content of dangerous components, not being able to vaporize at the same time, and not being completely vaporized. Achieve the effect of simple structure, saving maintenance and overhaul costs, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

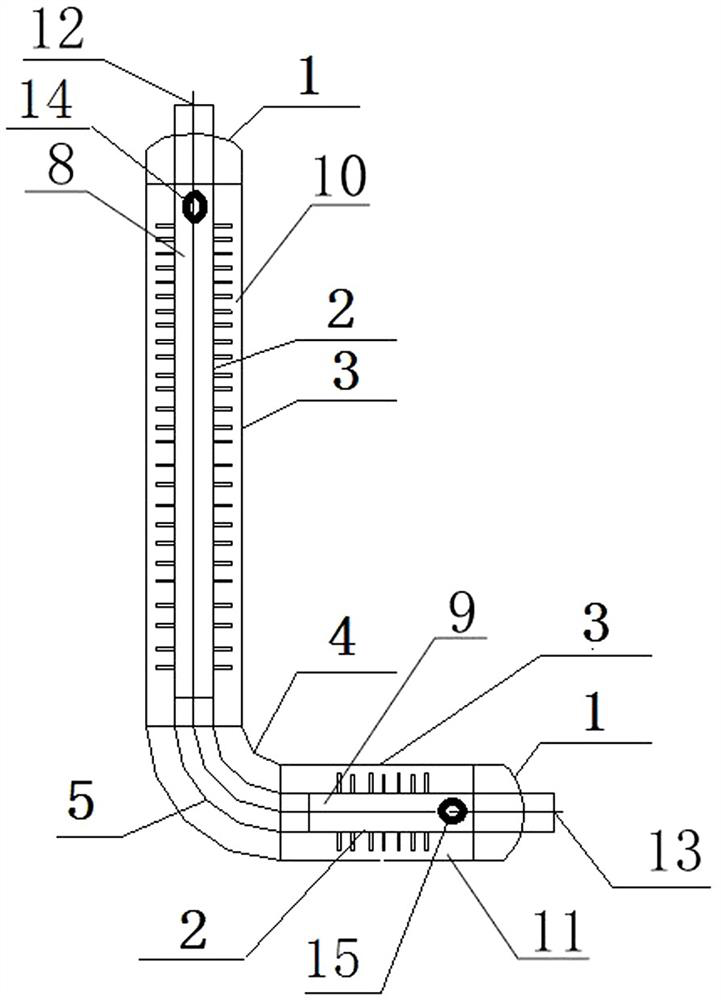

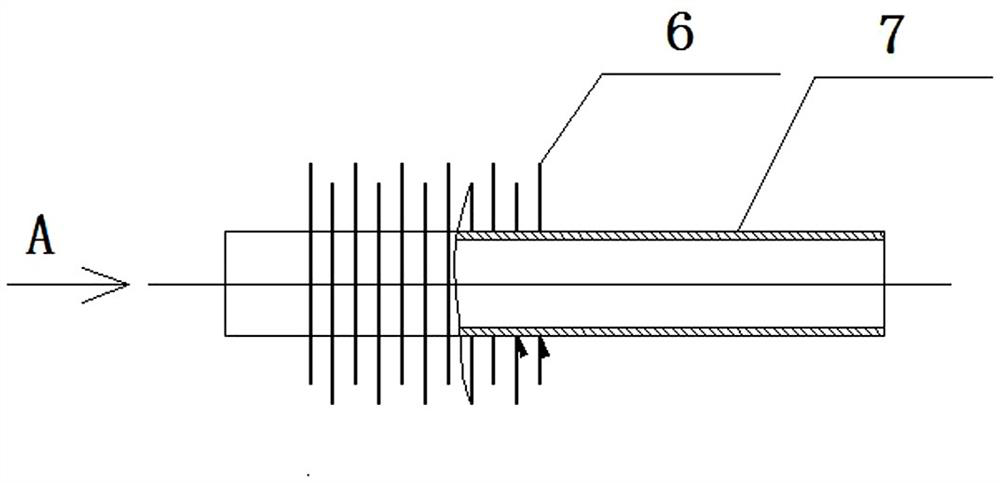

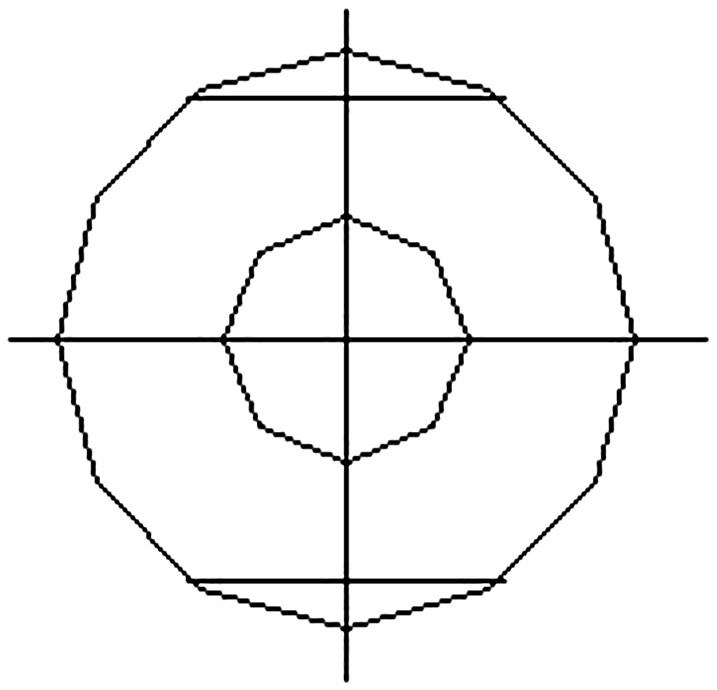

[0013] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-4 As shown, a new type of cryogenic liquid jacketed finned tube vaporization device is composed of an outer tube 3 and a finned tube 2 arranged in the outer tube, and the finned tube 2 is composed of a first finned tube and a second finned tube tubes, wherein the first finned tube 8 and the second finned tube 9 are vertically arranged, and a finned tube compensating elbow 5 is provided at the junction of the first finned tube 8 and the second finned tube 9 , an L-shaped inner tube 7 is formed between the first finned tube 8, the second finned tube 9, and the finned tube compensating elbow 5, and the outer tube 1 is also provided with the same structure as the inner tube 7. The first outer tube 10, the second outer tube 11, the outer tube compensating elbow 4, the first finned tube 8 is provided with a sampling gas outlet 12, and the second finned tube 9 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com