Large-flow high-stability Mach number wind tunnel rapid adjusting system and method based on temporary charging air source

A technology for adjusting the system and Mach number, which is applied in measurement devices, aerodynamic tests, testing of machine/structural components, etc. It can solve the problems of slow adjustment of outlet Mach number, poor repeatability of main valve, slow adjustment speed, etc. Fast adjustment, high precision, improved reliability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further explained below in conjunction with the accompanying drawings and specific implementation examples.

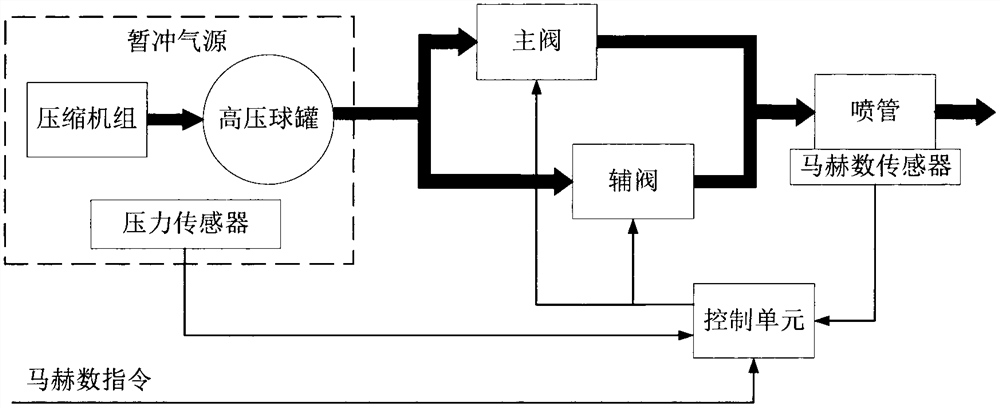

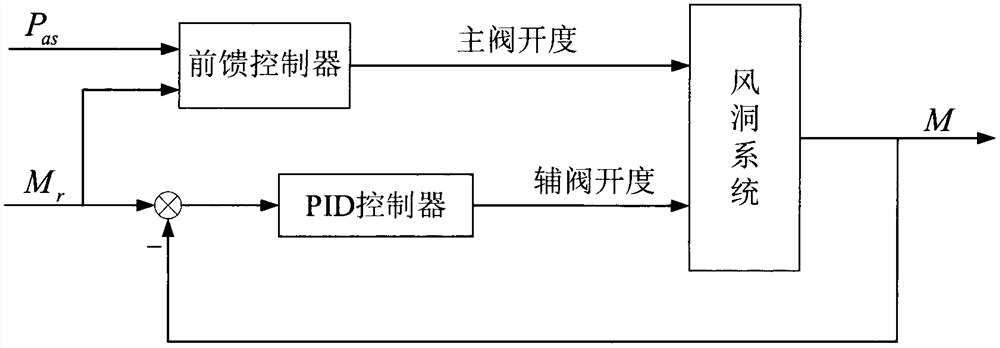

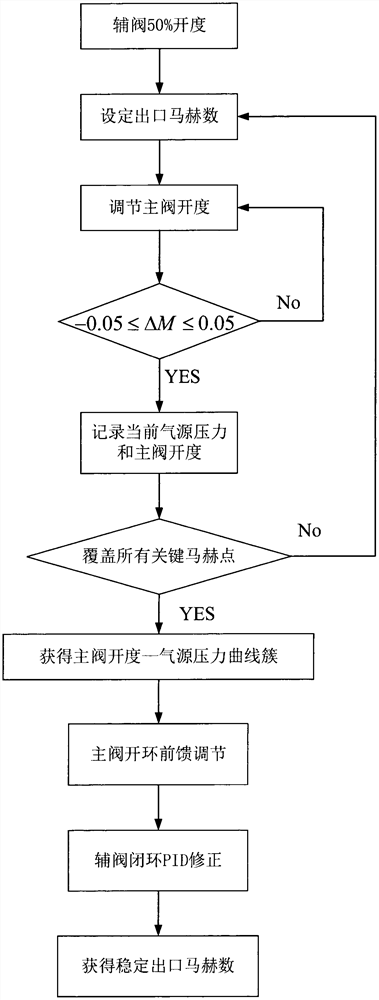

[0040] A flow chart of a fast adjustment system and method for a large-flow high-stable Mach number wind tunnel based on a temporary flushing gas source is shown in Fig. image 3 shown. The original temporary flushing wind tunnel system is equipped with a main valve, which is a large-flow butterfly valve with strong large-flow adjustment ability. It takes 30s to fully open, there is a dead zone between 0-10% of the opening, and there are problems of hysteresis and poor repeatability of up and down, which cannot well realize the precise adjustment of the Mach number at the exit of the wind tunnel. At the same time, due to its slow adjustment speed, the rapid drop in air source pressure will cause the time required for the Mach number at the outlet of the wind tunnel to be unstable. Therefore, on this basi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com