A method and system for monitoring the entire life cycle of equipment based on the Internet of Things

A technology of a full life cycle and monitoring system, applied in the field of equipment life cycle monitoring based on the Internet of Things, can solve the problems of inability to cope with environmental conditions, inability to understand the operating environment of the equipment, inability to understand the operating time of the equipment, etc., to improve the service life, The effect of avoiding equipment damage and facilitating equipment protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

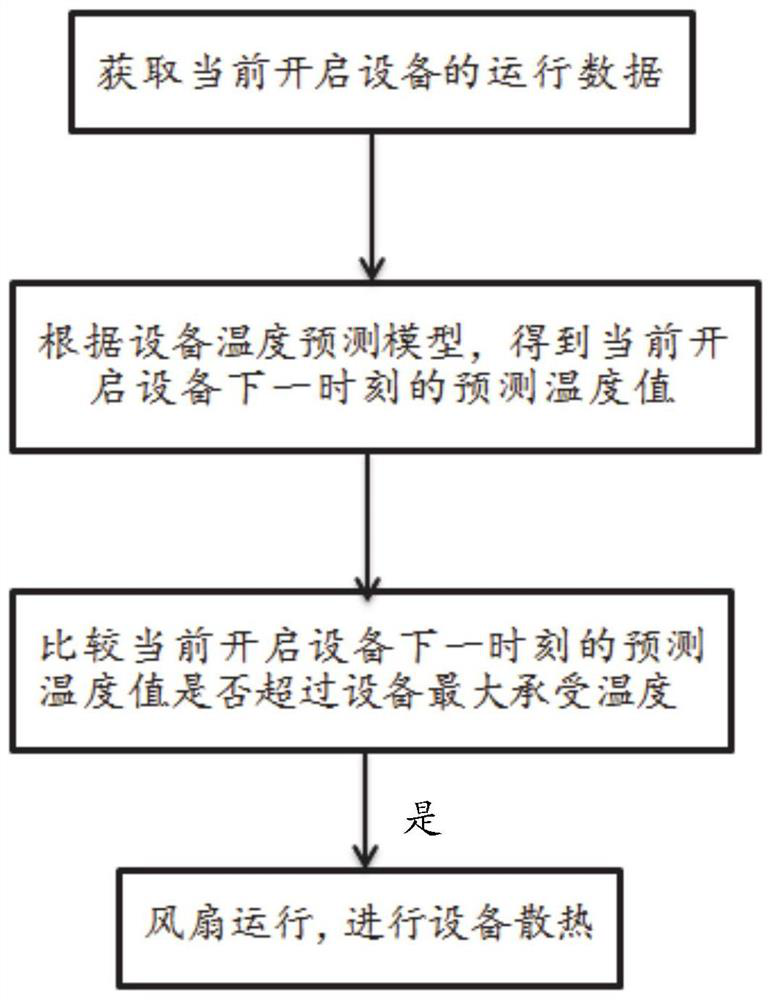

[0052] This embodiment discloses a method for monitoring the entire life cycle of equipment based on the Internet of Things, which specifically includes:

[0053] Obtain the operating data of the currently opened device, the operating data includes basic data, current operating data, and historical operating data, wherein:

[0054] The basic data includes the type of equipment, the specific time when the equipment starts to operate for the first time, the maximum temperature that the equipment can withstand, the maximum working time of the equipment, the service life of the equipment, and the location information of the equipment;

[0055]The running data of this time includes the current running time of the equipment (that is, the running time of the equipment from the time it starts running to the current time), the temperature data of the equipment running this time (that is, the temperature of the equipment from the time it started running this time to the current time) Da...

Embodiment 2

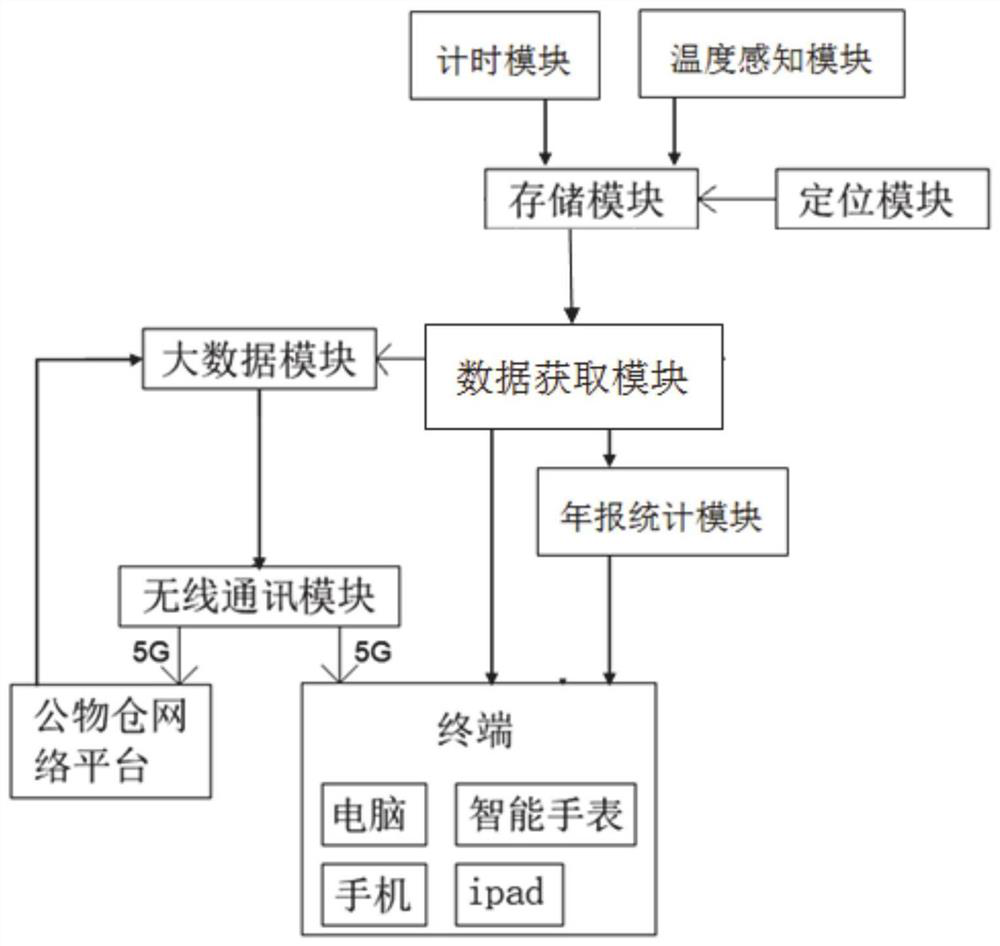

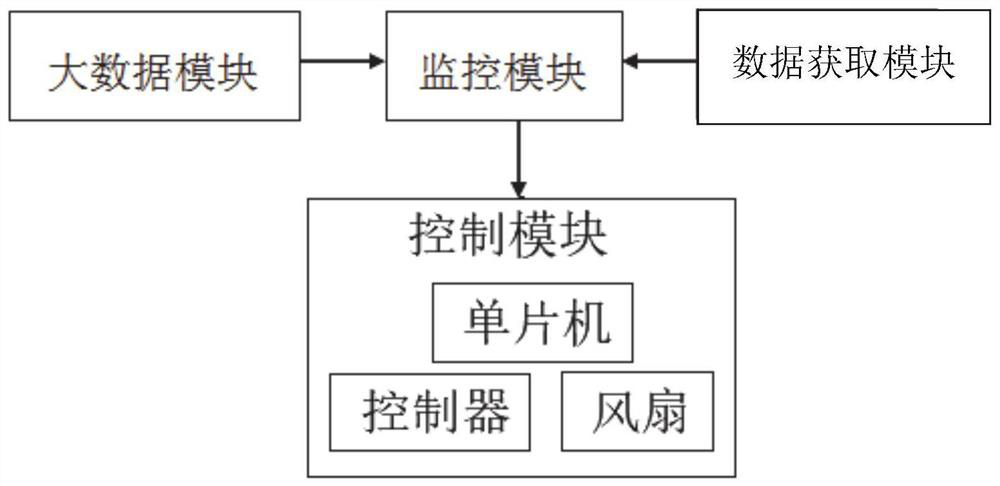

[0081] see Figure 2-Figure 4 , this embodiment discloses a device lifecycle monitoring system based on the Internet of Things, including a data acquisition module, a positioning module, a temperature sensing module, a control module, an alarm module, a monitoring module, a storage module, a wireless communication module, and a big data module , timing module, terminal and annual report statistics module;

[0082] The positioning module can accurately know the specific location of the device in a short time, and quickly find the device; and upload the specific location to the storage module, and the user terminal can obtain the specific location information of the device stored in the storage module through the data acquisition module; the positioning module is based on GPS, LBS positioning technology;

[0083] Temperature sensing module, the temperature sensing module includes a temperature sensor; the temperature sensor is a contact sensor, which monitors the currently turn...

Embodiment 3

[0103] This embodiment also provides a computer device, including a memory, a processor, and a computer program stored on the memory and operable on the processor. When the processor executes the program, the method described in Embodiment 1 is implemented. step.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com