Detection equipment and optical detection method

A testing equipment and optical testing technology, applied in optical testing for flaws/defects, material analysis by optical means, measuring devices, etc. High detection efficiency and accuracy, improved functional integration, and accurate positioning and navigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

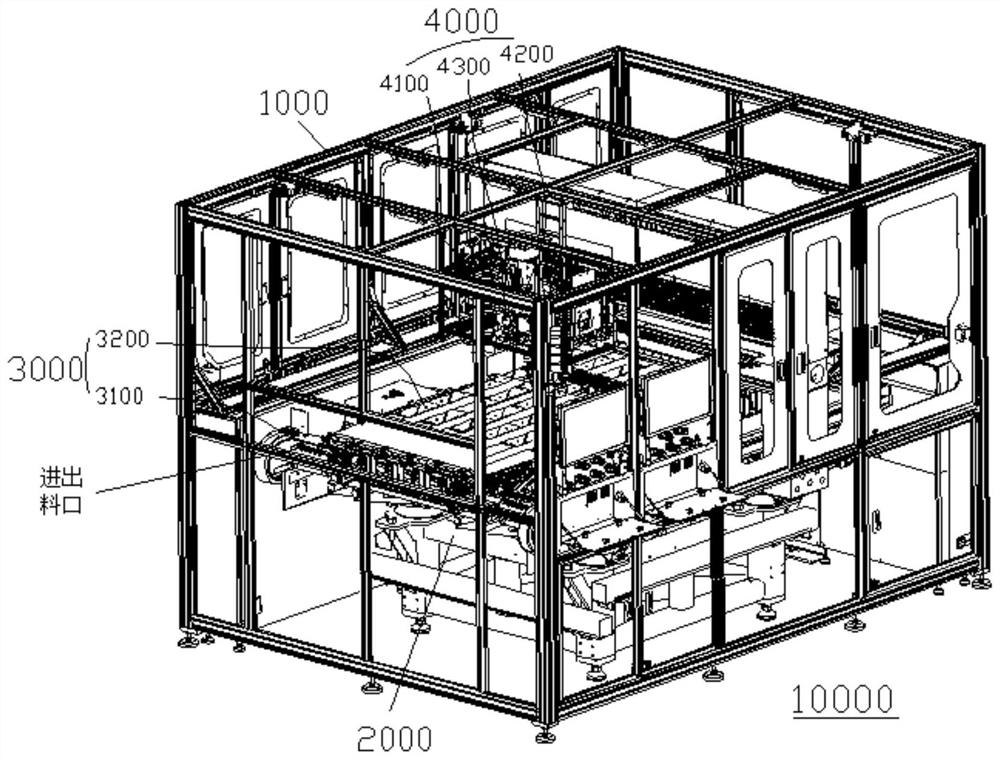

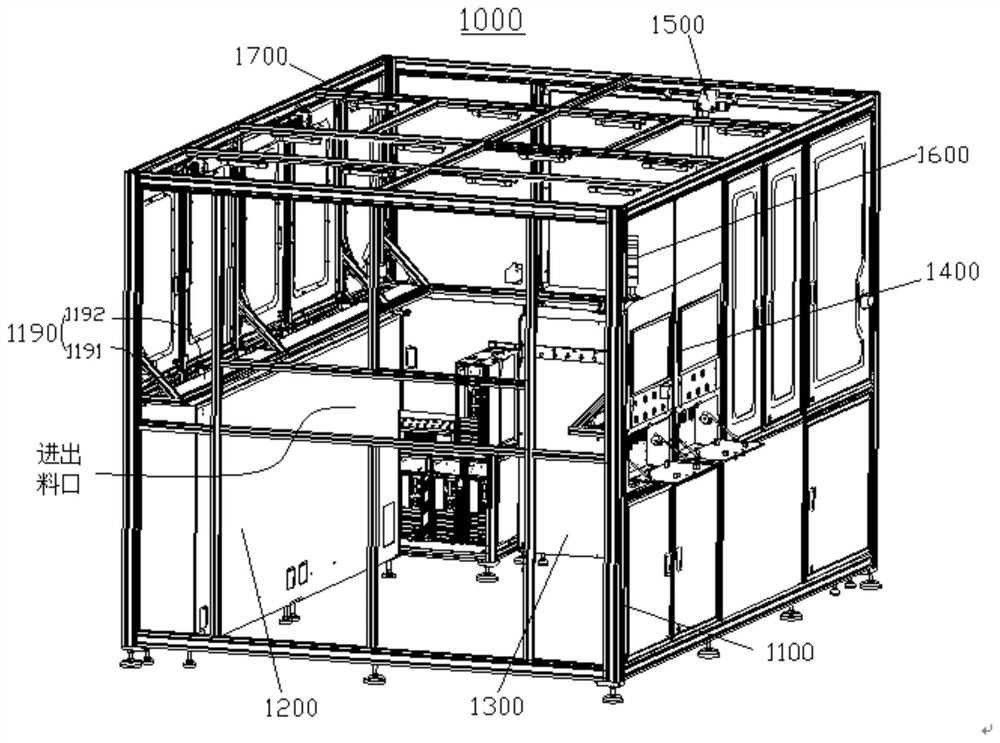

[0058] A detection device, see figure 1 , the detection equipment includes a functional outer box 1000 , a shock-absorbing stand 2000 , a platform module 3000 and an optical detection device 4000 .

[0059] Layout setting: the vibration-absorbing stand 2000 , the platform module 3000 and the optical detection device 4000 are non-rigidly connected or arranged at intervals in the functional outer box 1000 . Wherein, in the embodiment of interval setting, the minimum space between intervals is 3cm-20cm.

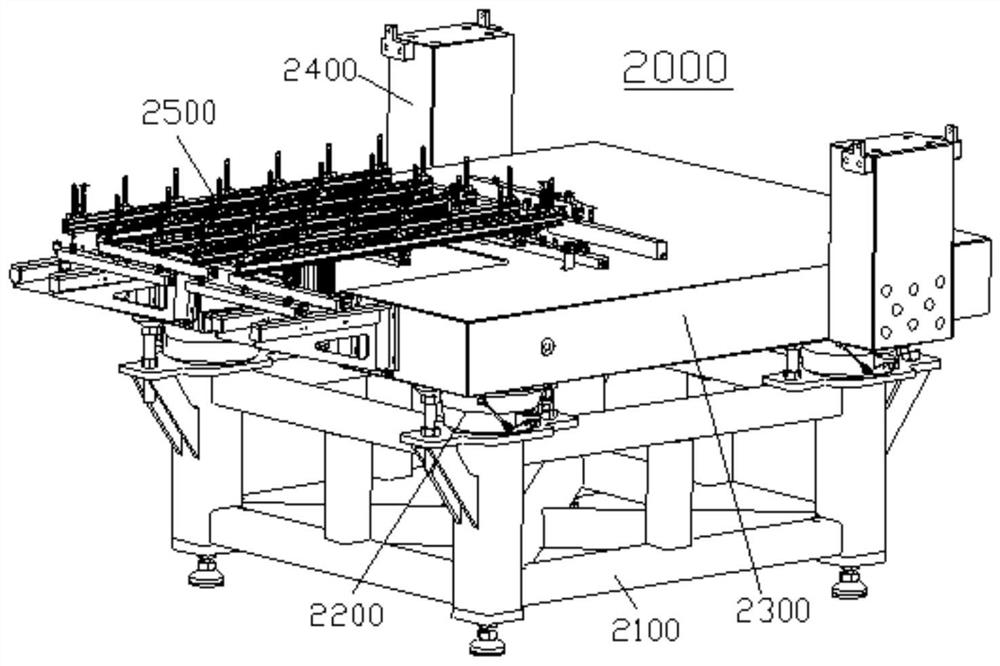

[0060] The platform module 3000 and the optical detection device 4000 are arranged on the vibration-absorbing stand 2000 .

[0061] The platform module 3000 is arranged on the shock absorbing platform 2000, and the platform module includes a transfer device 3100 and an air flotation platform 3200; the transfer device 3100 straddles the air flotation platform 3200 for treatment The test piece is transferred between the feeding port and the testing station. The air flotation pla...

Embodiment 2

[0112] An optical inspection method for a substrate-type object to be tested, the method includes the following steps.

[0113] S1 The initial positioning of material discharge, the substrate of the piece to be tested in the material box is transported to the transfer device 3100 of the platform module 3000 by manual or robotic hands, and the pre-check component 3140 of the transfer device 3100 performs a pre-detection whether there is a piece to be tested The substrate is sucked by the suction cup assembly 3160 from the lower surface, and the side rest assembly 3130 and the end rest assembly 3150 perform initial positioning.

[0114] S2 Feeding of the test piece, the two sets of side resting components 3130 retreat and the front end resting component 3150 retreats and descends below the substrate, and the transfer device 3100 transports the substrate of the test part to the air flotation platform along the feeding direction Detect initial bits on the 3200.

[0115] S3 detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com