Raw material crushing and mixing device for prestressed concrete pipe pile machining

A technology for crushing devices and raw materials, applied in mixers, mixers with rotary stirring devices, transportation and packaging, etc., can solve the problems of low crushing efficiency, screen extrusion deformation, difficult to control the range, etc., to improve the crushing efficiency. effect, ensure the effect of flowing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

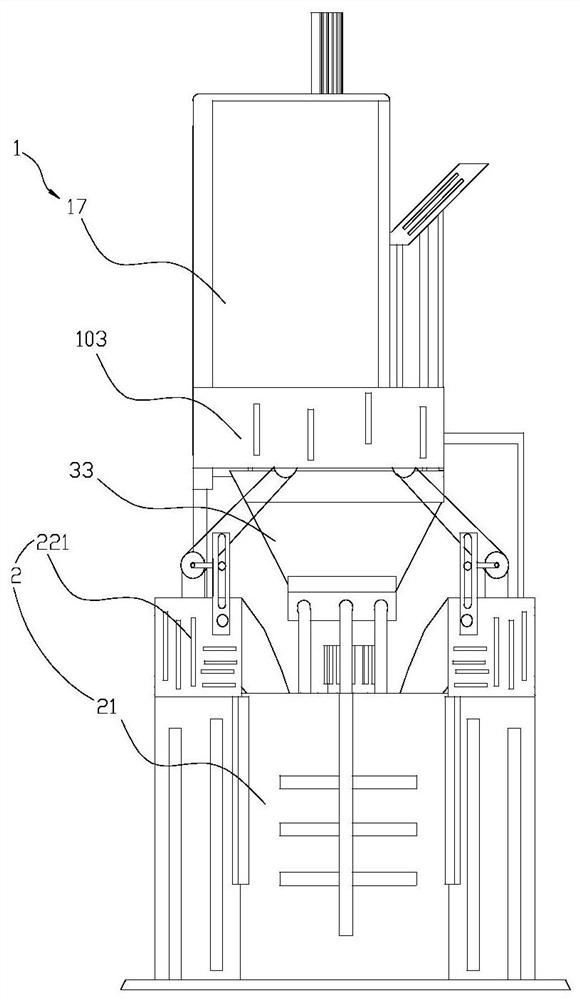

[0073] Such as figure 1 As shown, this embodiment discloses a raw material crushing and mixing device for processing prestressed concrete pipe piles, which includes a crushing device 1 and a mixing device 2 in sequence according to the process from first to last.

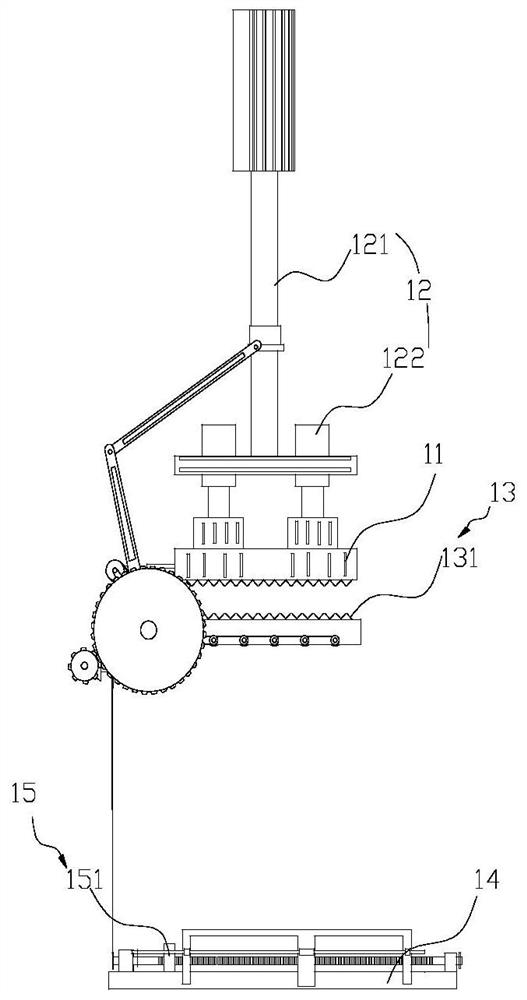

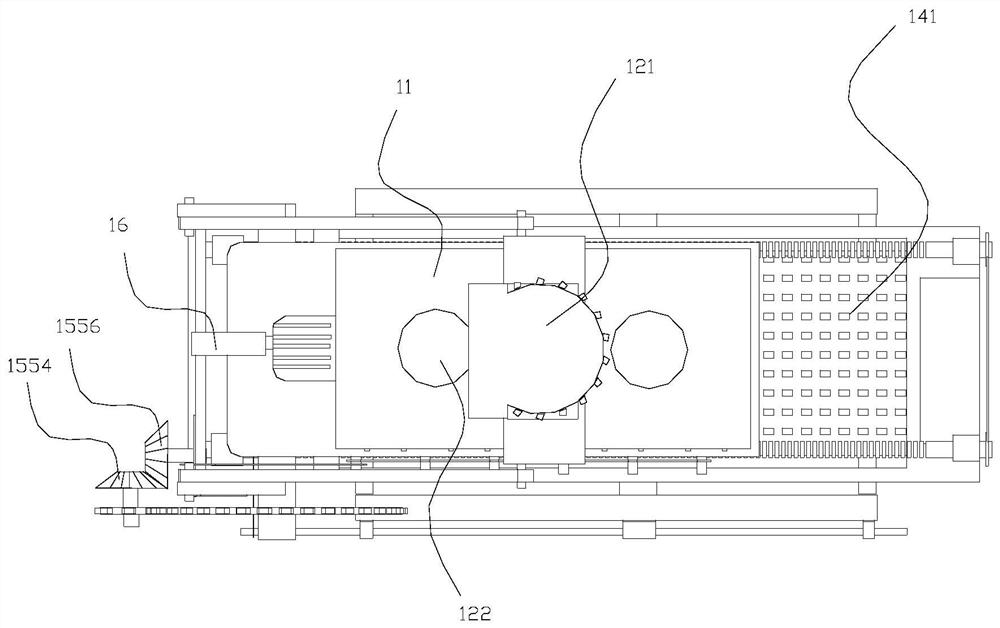

[0074] Such as Figure 2-5 As shown, the crushing device 1 includes an upper crushing member 11 , a lower pressing mechanism 12 , a supporting blanking member 13 , a lower material screen 14 , a pushing mechanism 15 , and a one-way rotation mechanism 16 . The upper crushing part 11 is located above the supporting blanking part 13, and the downward movement of the pressing mechanism 12 can drive the upper crushing part 11 to move downward.

[0075] A cyclic movement of the pressing mechanism 12 includes a single downward pressing movement stage, a reciprocating pressing movement stage, and a one-way rising and returning movement stage. In the stage of single downward pressure movement, the downward pressure movemen...

Embodiment 2

[0117] Such as Figure 4 As shown, the difference between this embodiment and the above-mentioned embodiments is that an upper protrusion 111 is provided on the bottom surface of the upper crushing member 11 , the tip of the upper protrusion 111 is downward, and a plurality of upper protrusions 111 are distributed in a matrix. A lower protrusion 1311 is disposed on the top surface of the lower support plate 131 , the tip of the lower protrusion 1311 is upward, and a plurality of lower protrusions 1311 are distributed in a matrix.

[0118] Since a plurality of upper protrusions 111 and lower protrusions 1311 are respectively arranged on the upper crushing part 11 and the lower support plate 131, the pressure for extruding the raw materials on the lower support plate 131 is increased, and the crushing force is improved.

[0119] The upper protrusion 111 and the lower protrusion 1311 also have a conical structure or a circular truncated structure.

[0120] Further, the projectio...

Embodiment 3

[0122] Such as Figure 18 , 23 , 24, the difference between this embodiment and the above-mentioned embodiment is that the middle of the installation frame 132 is hollowed out, and the side is provided with guide holes 13211, the main part of the lower support plate 131 is built in the middle hollow of the installation frame 132, the lower support plate 131 A part of the side protrudes from the corresponding guide hole 13211 . When the lower support plate 131 is horizontal, the bottom surface of a part of its side contacts with the inner bottom surface of the guide hole 13211 . The first rotating shaft 1841 is fixed to the installation frame 132 .

[0123] Further, part of the side of the lower support plate 131 can move up and down along the guide hole 13211, and the third cam shaft 1391 is also rotated on the mounting frame 132, and the third cam shaft 1391 is fixed with the third cam 1392 and the third cam shaft 1391. A transmission bevel gear 1393, the transition shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com