Automatic drying and heated air circulation energy-saving device for graphene underfloor heating

A hot air circulation and energy-saving device technology, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problem of single function of the heating device, cannot cool down, can only be heated, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

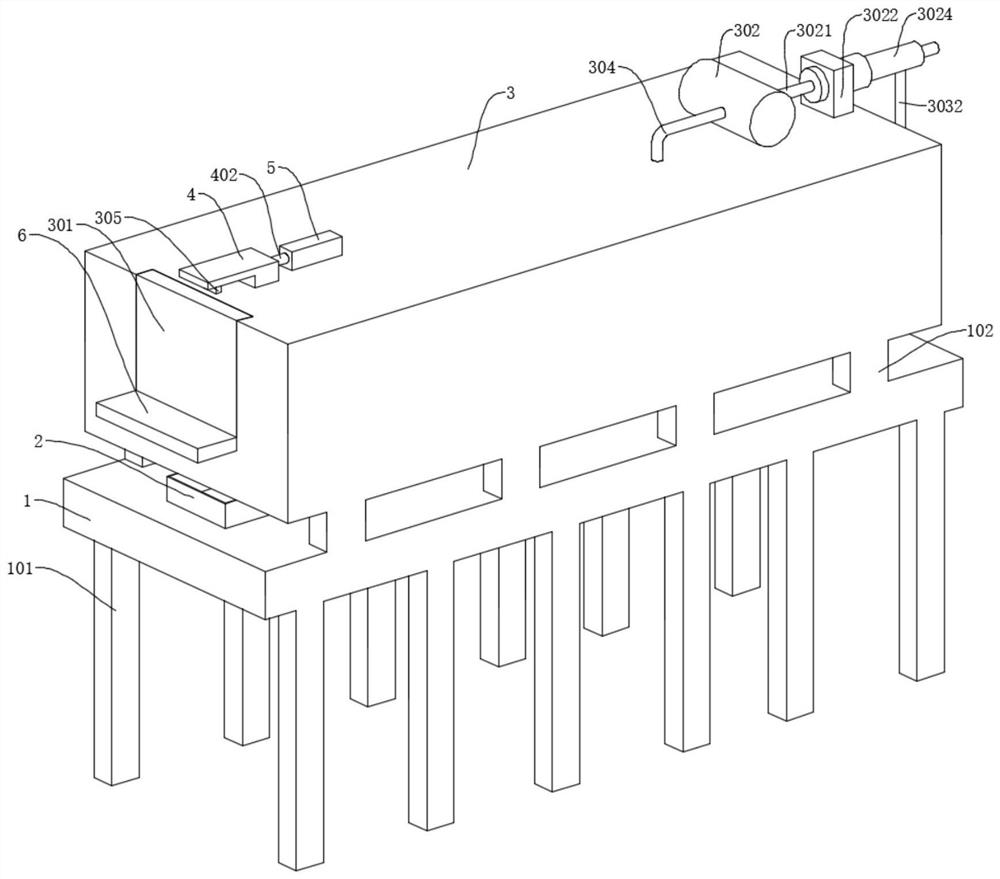

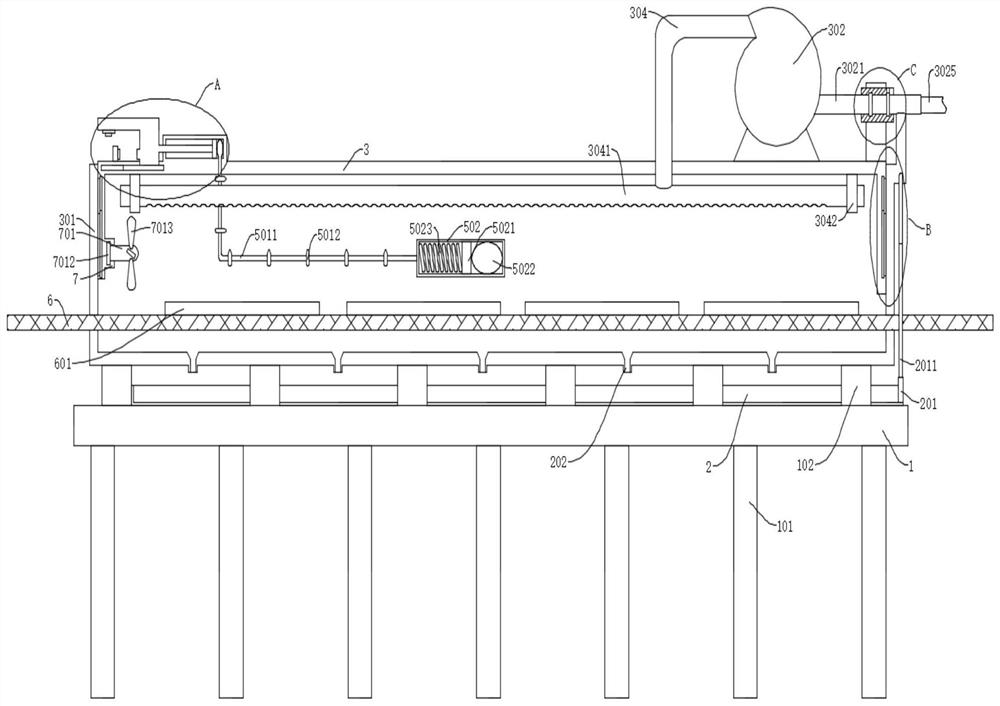

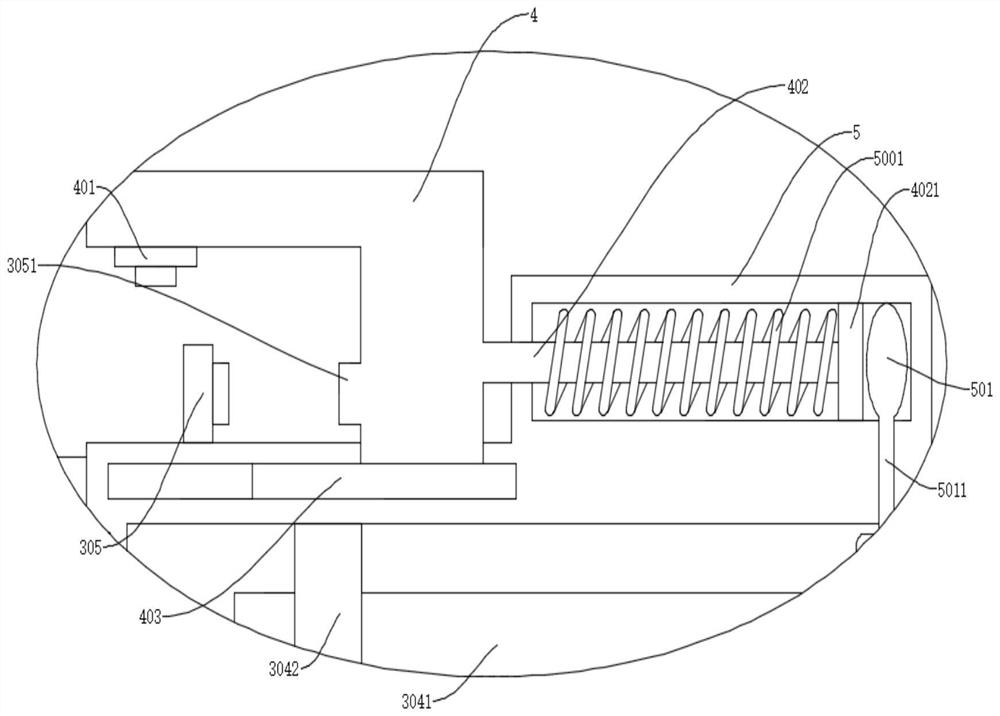

[0027] refer to Figure 1-5 , a graphene floor heating automatic drying, hot air circulation energy-saving device, including a workbench 1, a drying box 3 is fixedly connected to the workbench 1, a steel belt 6 is slidably connected to the inside of the drying box 3, and a steel belt 6 is placed on the steel belt 6 Electric heater 601, fan 302 is fixedly connected on drying box 3, air inlet pipe 304 and exhaust pipe 3021 are fixedly connected on fan 302, ventilation pipe 3041 is fixedly connected in drying box 3, and ventilation pipe 3041 is provided with Vent, the air inlet pipe 304 is fixedly connected to the ventilation pipe 3041, the drying box 3 is fixedly connected to the connection block 3023, the exhaust pipe 3021 is fixedly connected to the connection block 3023, and the connection block 3023 is slidably connected to the connection pipe 3024. The connecting pipe 3024 is fixedly connected with the hot air pipe 3025, the right end of the drying box 3 is slidably connect...

Embodiment 2

[0030] refer to Figure 1-5 , is basically the same as in Embodiment 1, and furthermore, a fixed block 7 is fixedly connected in the drying box 3, a rotating shaft 701 is rotatably connected to the fixed block 7, a blade 7013 is fixedly connected to the rotating shaft 701, and a blade 7013 is fixedly connected to the rotating shaft 701. The swivel 7012 is rotatably connected in the fixed block 7, the first fixed frame 4 is fixedly connected with the second switch 401 for controlling the rotation of the rotating shaft 701, and the second door 301 is offset against the second switch 401.

Embodiment 3

[0032] refer to Figure 1-5 , is basically the same as that of Embodiment 1, furthermore, the workbench 1 is fixedly connected with the water collecting tank 2, the drying box 3 is fixedly connected with the drain pipe 202 matched with the water collecting tank 2, and the water collecting tank 2 is slidably connected with a plug The plate 201 and the blocking plate 201 are fixedly connected with a second fixing frame 2011 , and the second fixing frame 2011 is fixedly connected with the first box door 303 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com