Construction method for preparing engineering bag by curing marine sludge

A construction method and engineering bag technology, which are applied in chemical instruments and methods, infrastructure engineering, fixed/solidified sludge treatment, etc. The effect of improving sludge pretreatment efficiency, saving resources and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

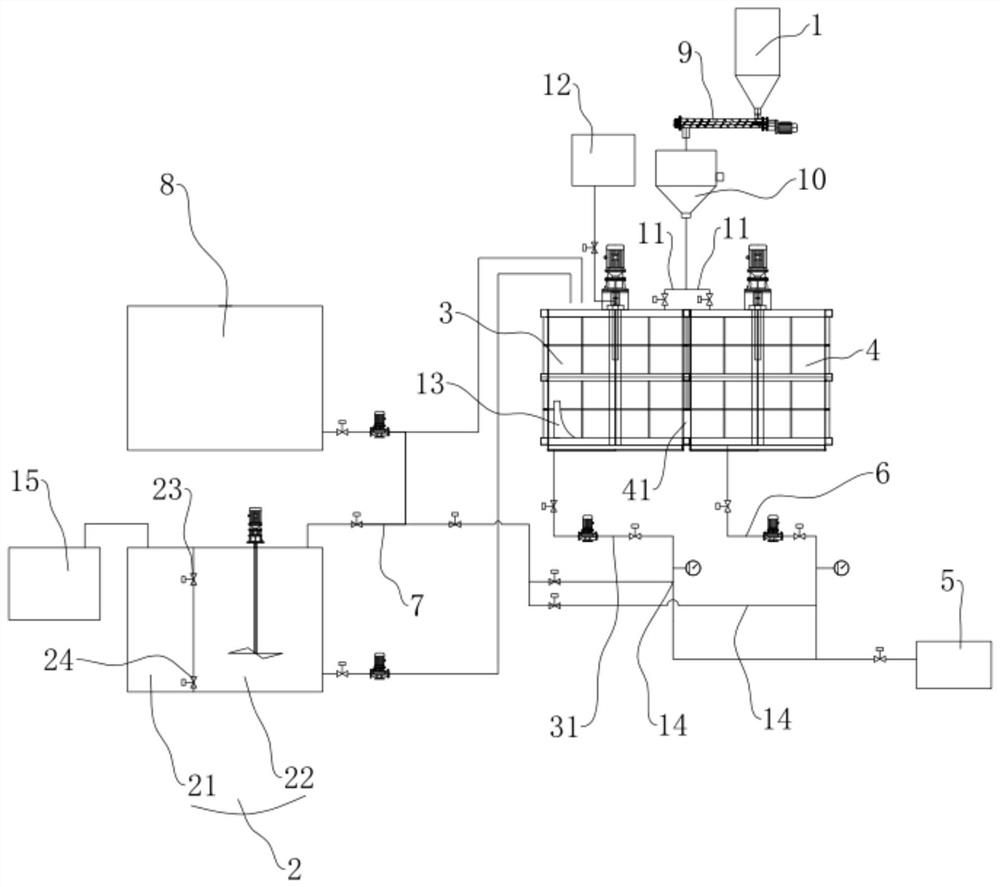

[0032] refer to Figure 1 to Figure 2 Further explain the construction method of preparing engineering bags from marine silt solidification. A construction method for solidifying marine silt to prepare engineering bags, such as figure 1 shown, including the following steps:

[0033] S1. Prepare the curing agent slurry, put the curing agent into the curing agent storage tank 1 and stir temporarily; wherein, the curing agent is equipped with a solid curing agent and a liquid curing agent, and the curing agent storage tank 1 stores the solid curing agent and the curing agent The discharge end of the storage tank 1 is sent to the metering scale 10 for metering through the screw conveyor 9, so as to be added quantitatively. The liquid curing agent is stored and supplied through the liquid curing agent adding system 12. The liquid curing agent adding system 12 is composed of an infusion pipe and a flow rate Valve supply, quantitative addition through the flow valve;

[0034] S2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com