Organic fertilizer production process

A production process and technology of organic fertilizer, applied in the directions of organic fertilizer, fertilization device, excretion of fertilizer, etc., can solve the problems of low production quality of organic fertilizer, inconvenient transportation of sheep manure, inconvenient sheep manure screening, etc., and achieves good crushing effect, The effect of saving manpower and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

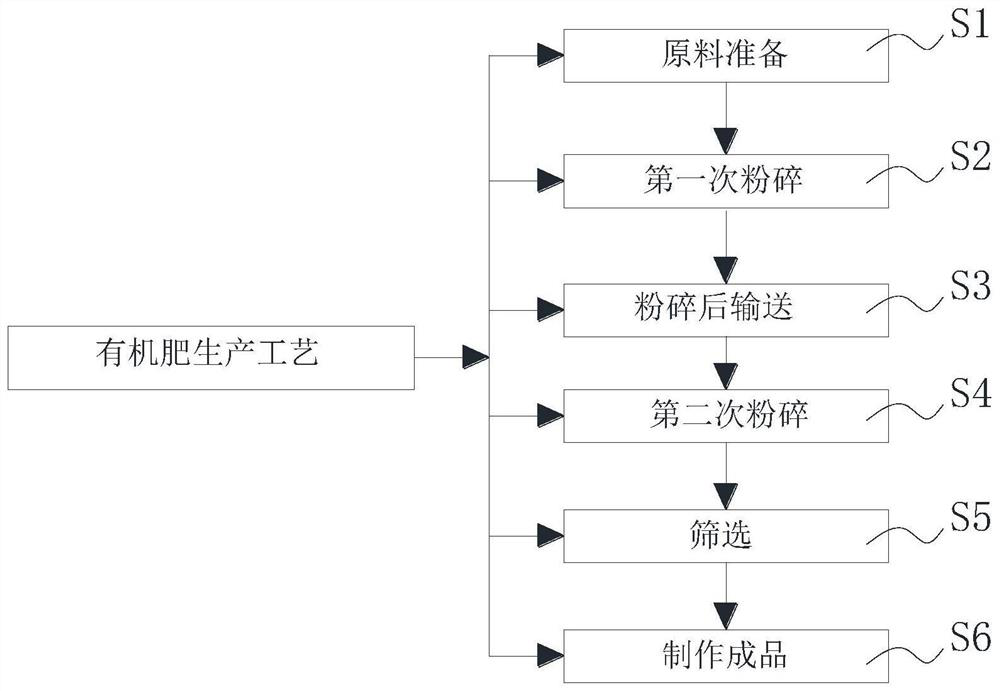

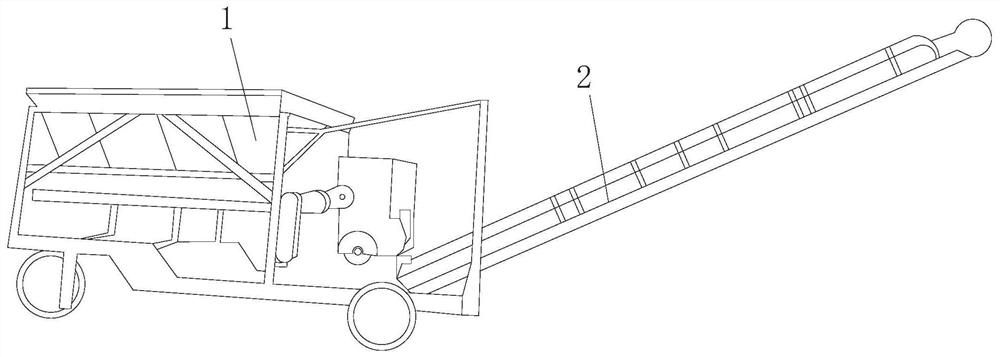

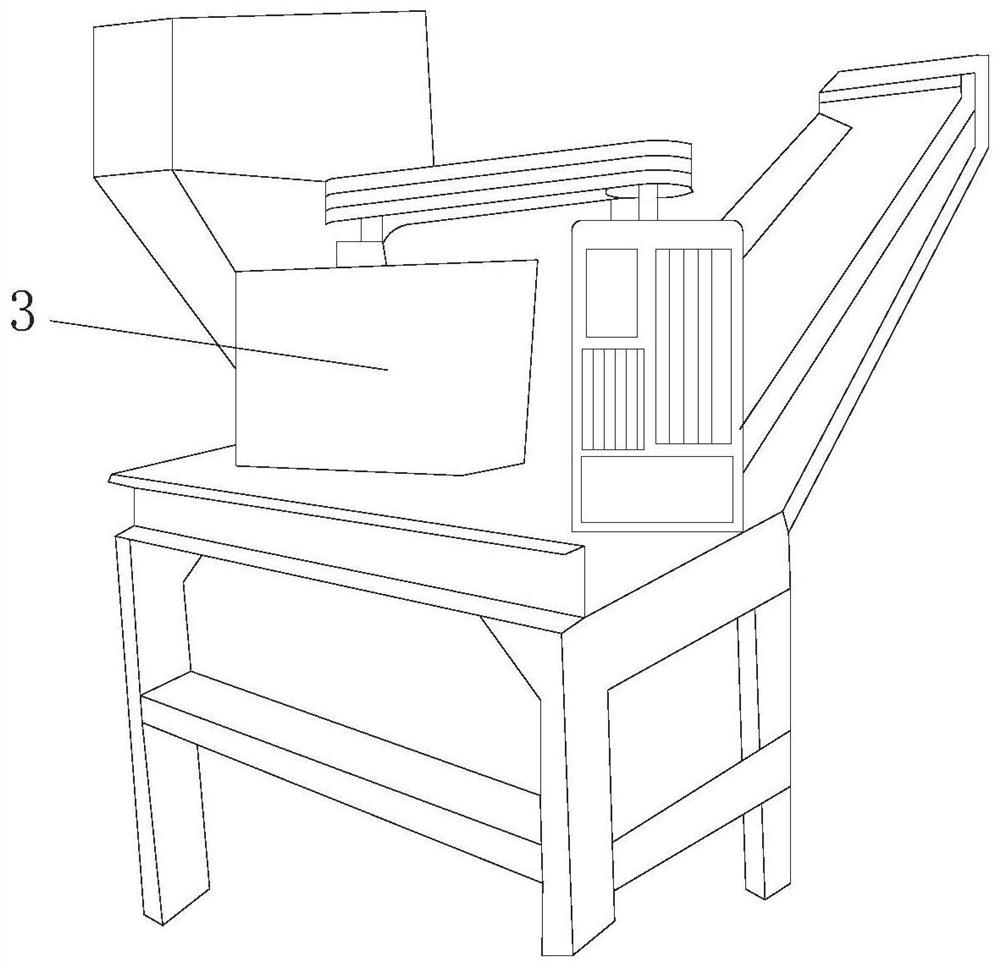

[0030] Please refer to figure 1 , figure 2 , image 3 with Figure 4 ,among them, figure 1 A structural block diagram of a preferred embodiment of the organic fertilizer production process provided by the present invention; figure 2 Schematic structural diagram of a large sheep pulverizer in the organic fertilizer production process provided by the present invention; image 3 The structural diagram of small sheep gelatin pulverizer for the organic fertilizer production process provided by the present invention; Figure 4 Schematic structural diagram of screening in the organic fertilizer production process provided by the present invention. Organic fertilizer production process includes the following steps:

[0031] S1, raw material preparation: In the production of organic fertilizers, it is necessary to prepare a sufficient amount of fermented sheep mances to be subsequent production;

[0032] S2, first crushing: the first time the sheep prepared in S1 is first pulverized, and it is...

Embodiment 2

[0046] Please refer to figure 1 , figure 2 , image 3 with Figure 4 ,among them, figure 1 A structural block diagram of a preferred embodiment of the organic fertilizer production process provided by the present invention; figure 2 Schematic structural diagram of a large sheep pulverizer in the organic fertilizer production process provided by the present invention; image 3 The structural diagram of small sheep gelatin pulverizer for the organic fertilizer production process provided by the present invention; Figure 4 Schematic structural diagram of screening in the organic fertilizer production process provided by the present invention. Organic fertilizer production process includes the following steps:

[0047] S1, raw material preparation: In the production of organic fertilizers, it is necessary to prepare a sufficient amount of fermented sheep mances to be subsequent production;

[0048] S2, first crushing: the first time the sheep prepared in S1 is first pulverized, and it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com