A superhydrophobic diurnal passive radiation cooling porous film and its preparation method

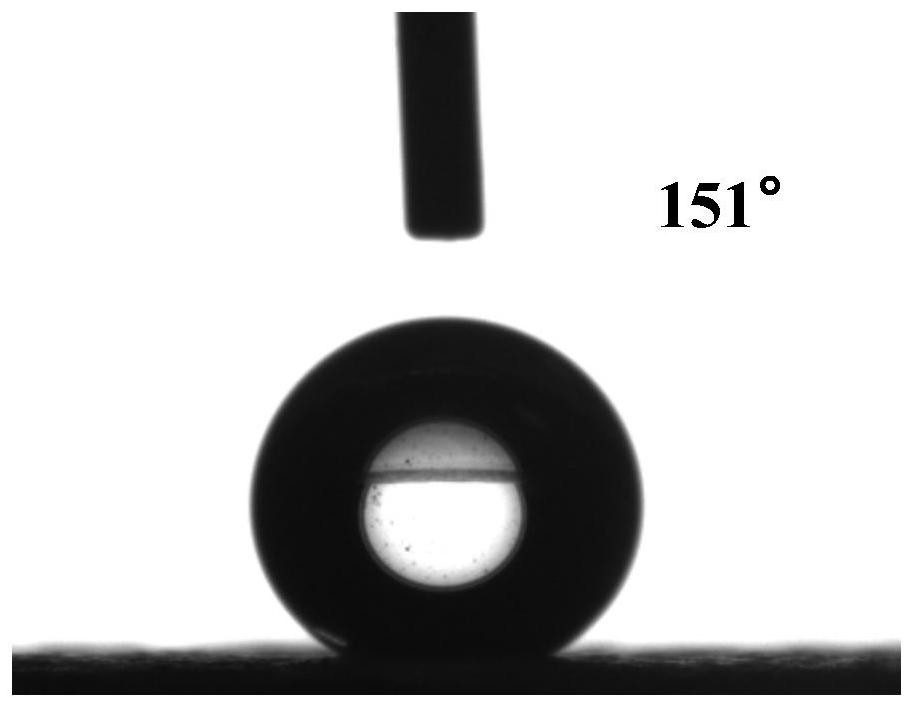

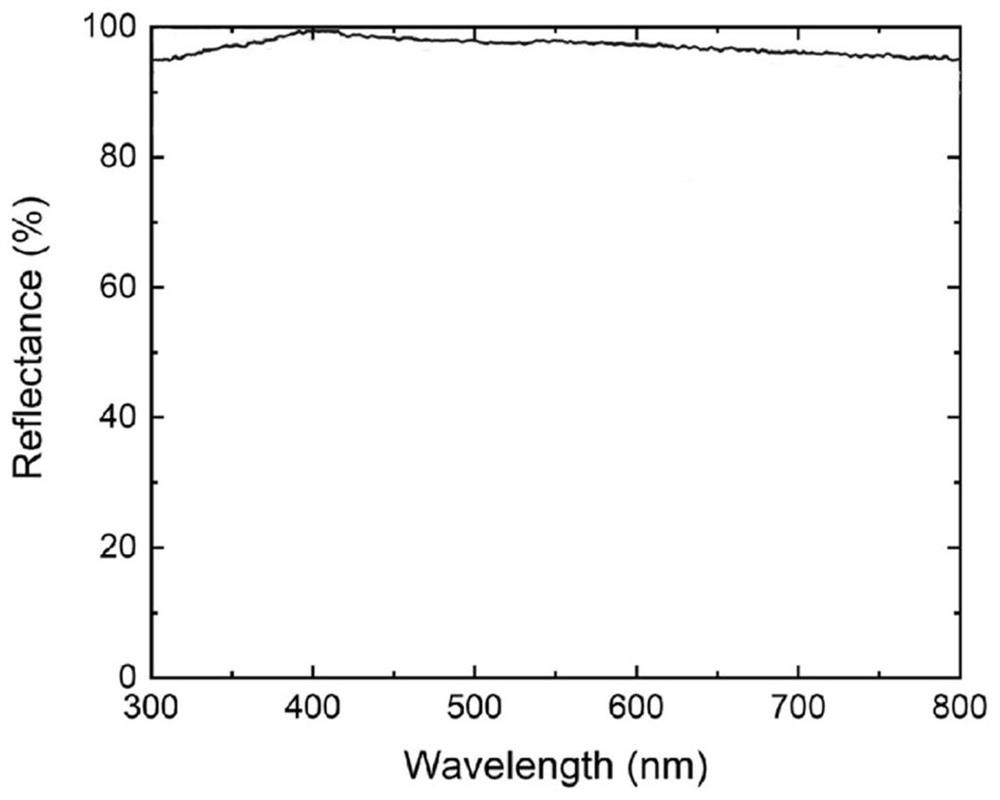

A radiative cooling, super-hydrophobic technology, applied in reflective/signal coatings, coatings, etc., can solve the problems of increasing cost and cycle, increasing preparation difficulty, etc., and achieves a wide range of applications, good spectral selectivity, and improved cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

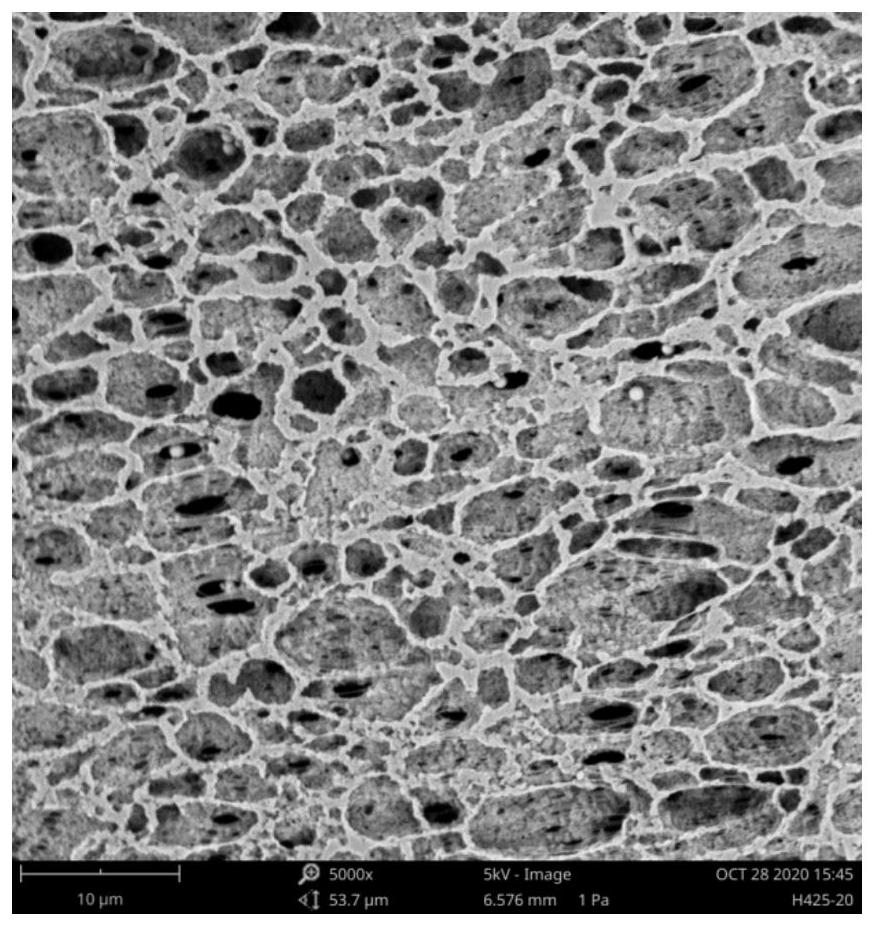

[0047]The prepared precursor solution was coated on the surface of the glass substrate by drop casting, and dried in an oven at 80° C. to obtain a porous film with a thickness of 175 μm.

Embodiment 2

[0049] The obtained precursor solution was coated on the surface of the glass substrate by drop casting, and dried in an oven at 80° C. to obtain a porous film with a thickness of 265 μm.

Embodiment 3

[0051] The prepared precursor solution was coated on the surface of the glass substrate by drop casting, and dried in an oven at 80° C. to obtain a porous film with a thickness of 327 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com