Method and device for accurately measuring temperature of SCR catalytic unit

A technology of SCR catalytic converter and catalytic unit, applied in the direction of muffler device, exhaust device, electronic control of exhaust gas treatment device, etc., can solve the problems of insufficient utilization of catalytic converter efficiency, inaccurate temperature measurement, etc., to reduce production costs and user cost, improve operating efficiency, and improve the effect of economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

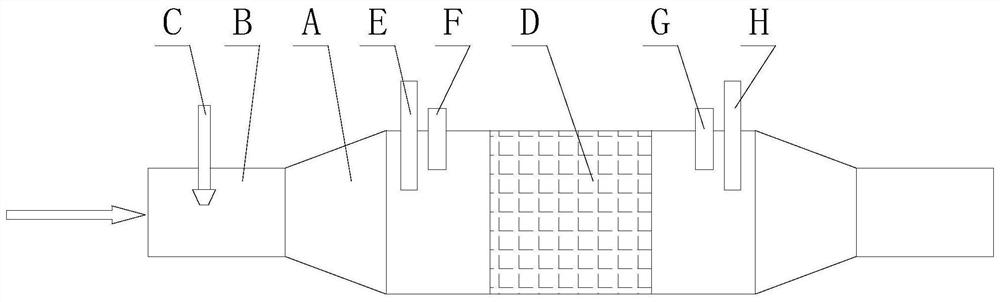

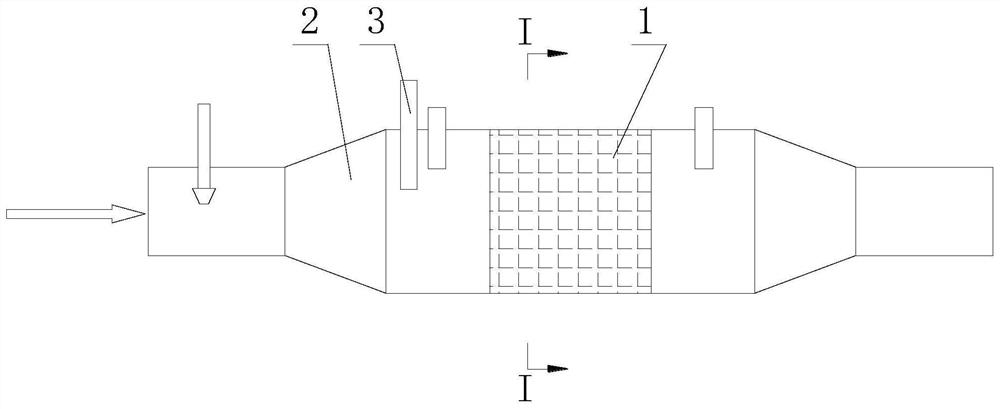

[0035] refer to image 3 , 4 , a method for accurately measuring the temperature of an SCR catalytic unit comprising:

[0036] In the experimental environment, obtain the temperature T of the front end of the SCR catalytic unit 1; obtain the temperatures T1-Tn of n different positions on the periphery of the circumference of the middle part of the SCR catalytic unit 1; obtain the temperature Tn+1 of the central position of the central part of the SCR catalytic unit 1;

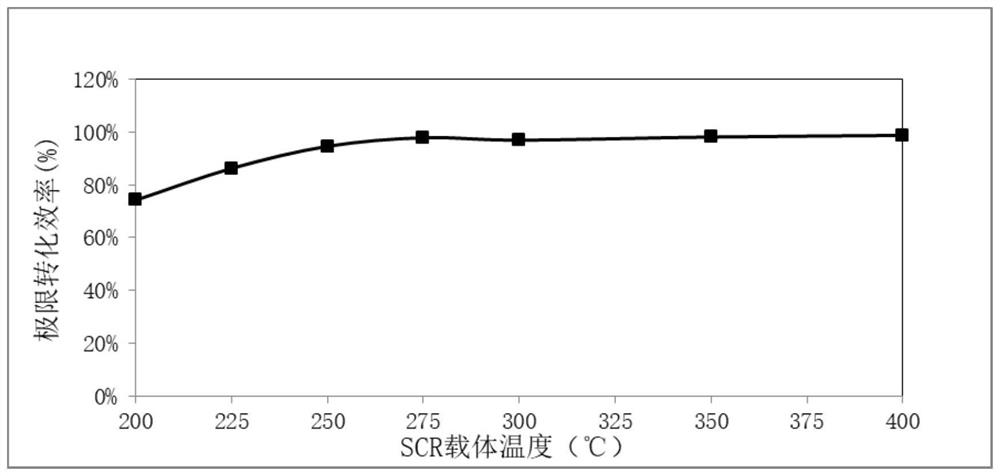

[0037] Adjust the working conditions of the engine according to the set temperature interval, so that the temperature T gradually rises from the first temperature to the second temperature, and run stably for the set time at each working point. After the set time is reached, record each working condition Points corresponding to T, T1~Tn, Tn+1, calculate the correction coeff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com