Active and passive composite electromagnetic vibration isolation device and design method thereof

A composite electromagnetic, active and passive technology, used in shock absorbers, mechanical equipment, non-rotating vibration suppression, etc., can solve the problems of high energy consumption, complex active vibration isolation design structure, inability to meet low frequency vibration isolation, etc., to achieve enhanced reliability. performance, transient response and anti-interference ability improvement, and the effect of optimal vibration isolation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

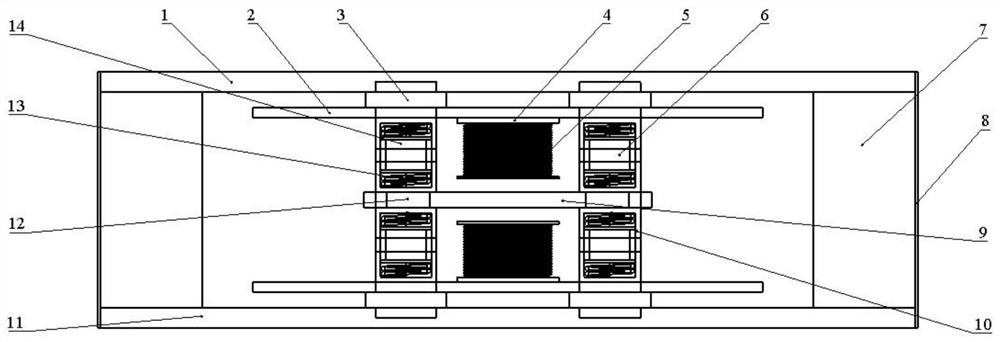

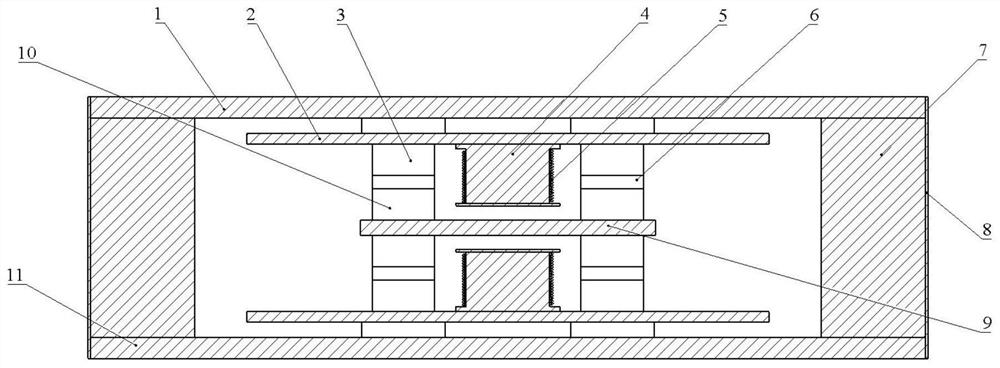

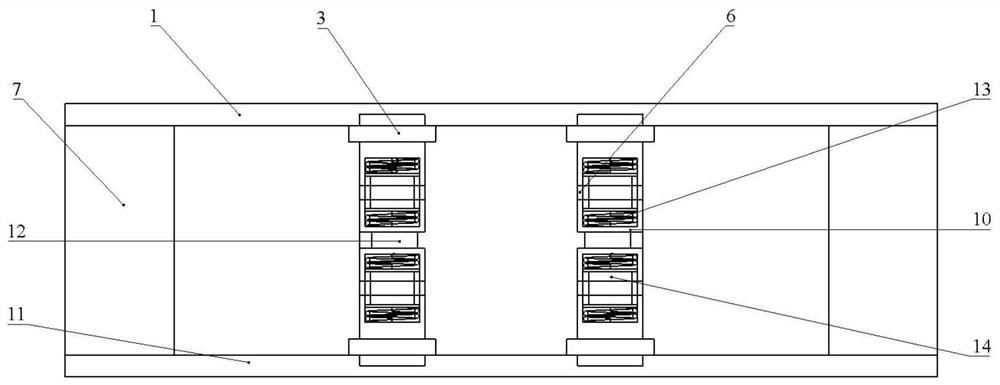

[0030] see Figure 1-4 , an active and passive composite electromagnetic vibration isolation device, including a cylindrical housing 8, the cylindrical housing 8 is provided with an upper end cover 1 and a lower end cover 11; the cylindrical housing 8 is provided with a stator frame 4, an electromagnetic coil 5 , armature 9 constitutes an electromagnetic actuator, and the electromagnetic actuator is an active vibration isolation device; the power is composed of a T-shaped concave pillar 3, a ring-shaped rubber pad 6, a cylindrical concave pillar 10, a steel spring 13, and an I-shaped mass block 14 The vibration absorption unit, the dynamic vibration absorption unit and the rubber vibration isolator 7 are connected in parallel to form a passive vibration isolation device; the active vibration isolation device and the passive vibration isolation device are connected in series through the upper end cover 1, the four-hole disc 2, the lower end cover 11, and the arc-shaped mass bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com