A feeder automatic on-site automatic test method and system

An automatic test system and feeder automation technology, applied in the direction of detecting faults and fault locations according to conductor types, can solve the problem of not being able to determine whether the coordination of multiple feeder terminals meets the requirements of system operation, unable to explain the behavior of the tested feeder terminals, and no Problems such as injected fault current and voltage are given to achieve the effect of reliable test results, comprehensive test and reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

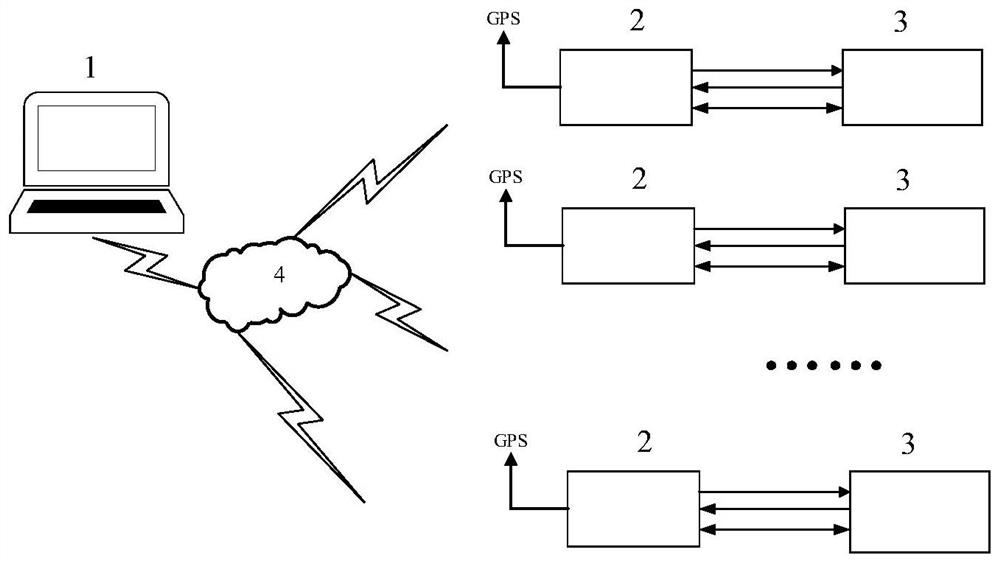

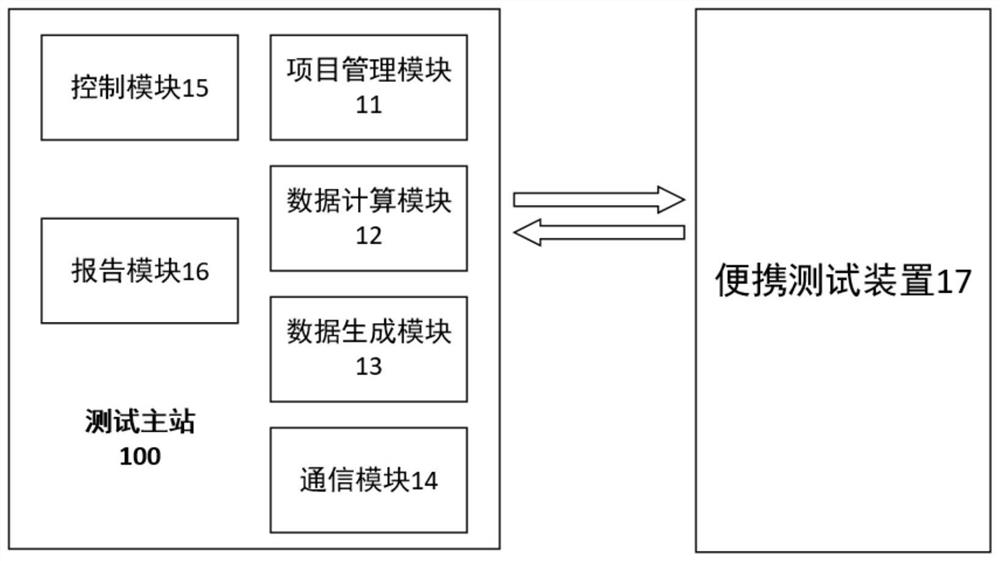

[0061] The principles and features of the present invention will be described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

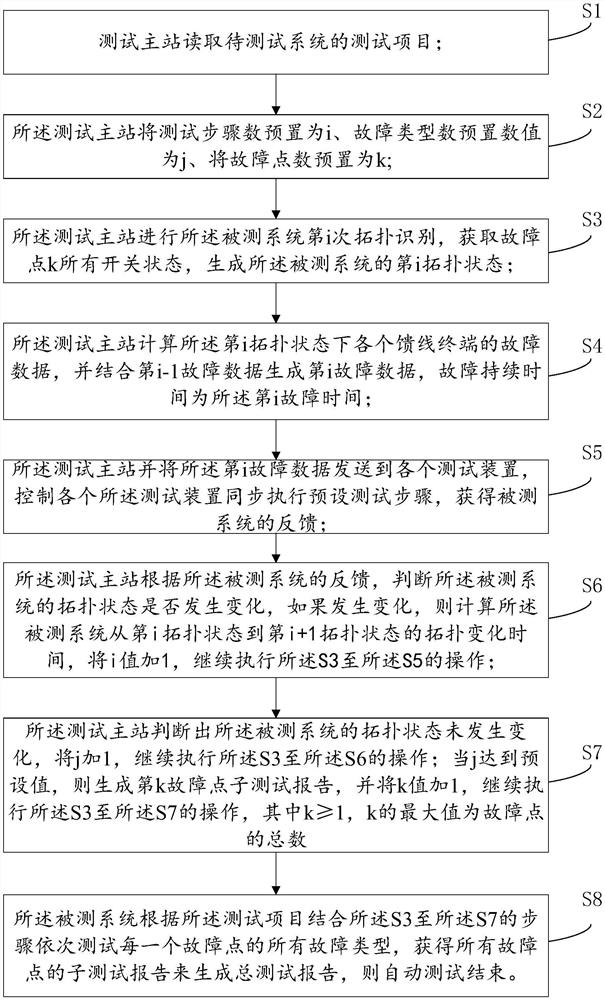

[0062] like figure 1 As shown, a kind of feeder automatic on-site automatic testing method provided by the embodiment of the present invention includes:

[0063] S1, the test master station reads the test items of the system to be tested, including: fault point, fault type and fault duration;

[0064] S2, the test master station presets the number of test steps as i, the number of fault types as j, and the number of fault points as k;

[0065] S3, the test master station performs the i-th topology identification of the system under test, obtains all switch states of the fault point k, and generates the i-th topology state of the system under test;

[0066] S4, the test master station calculates the fault data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com