Anti-reflection and near-infrared laser prevention resin lens

A technology of infrared laser and resin lens, which is applied in optics, optical parts, optical components, etc., can solve problems such as poor temperature resistance, poor temperature resistance and environmental resistance, and limited use effects, so as to avoid high stress and reduce bad Matching effect, the effect of improving high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

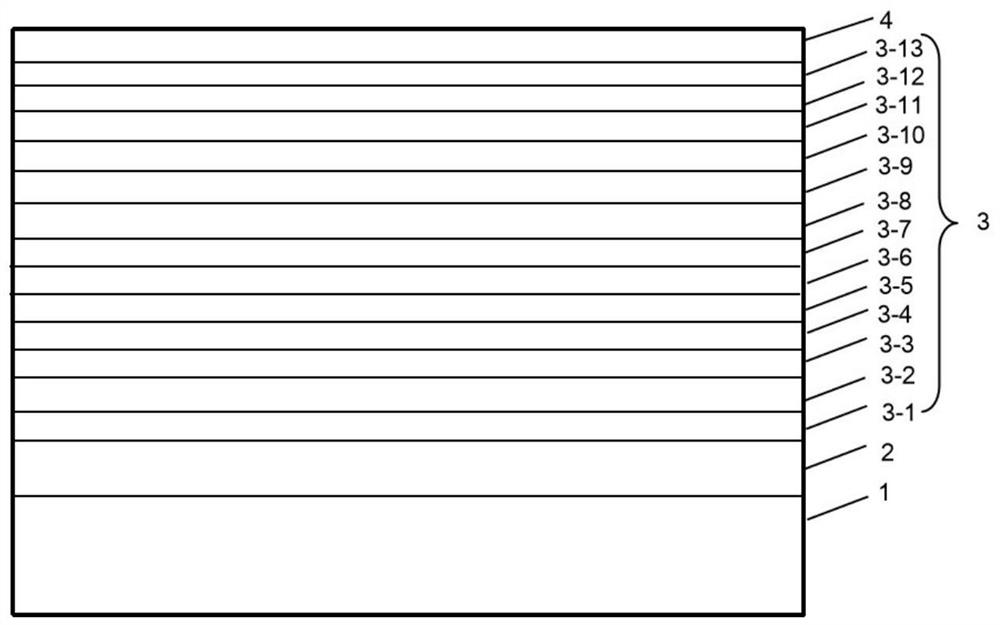

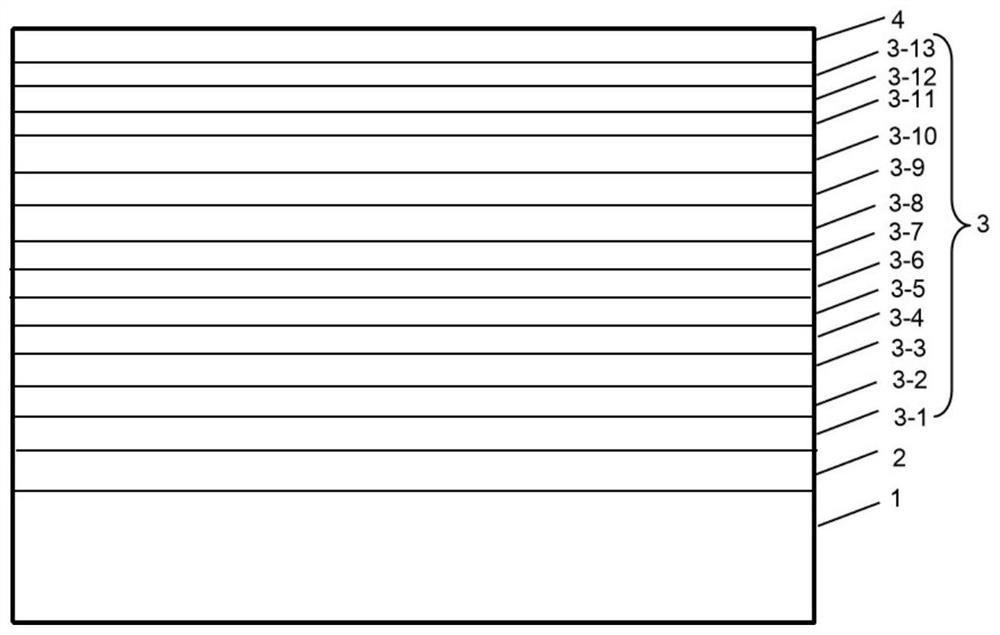

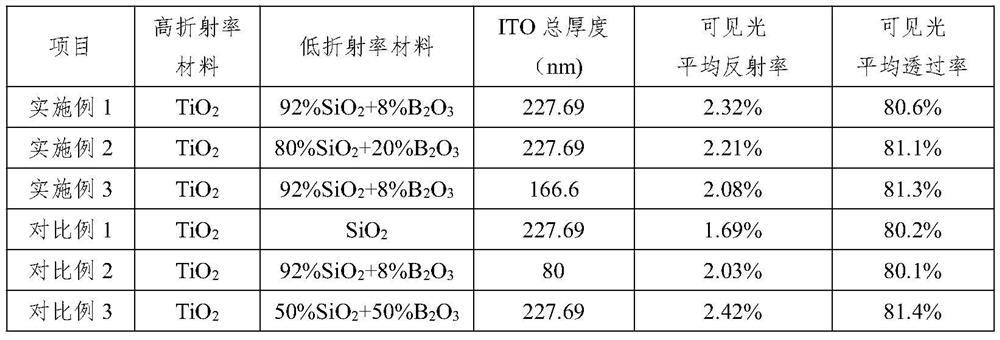

[0083] An anti-reflection and anti-near-infrared laser resin lens, which includes: a resin lens substrate 1 (MR-8); a hardening layer 2 (Z117) / 2.6-3 μm; an anti-reflection layer 3 including: a silicon-boron composite oxide layer 3-1 (where SiO 2 and B 2 o 3 Mole percent: 92% SiO 2 , 8% B 2 o 3 ; Entrust Changzhou Zhanchi Photoelectric Technology Co., Ltd. to develop and produce, the material model is BL08) / 24.2nm, ITO layer 3-2 / 27.51nm, silicon boron composite oxide layer 3-3 / 9.18nm (material is the same as 3- 1), TiO 2 Layer 3-4 / 73.78nm, silicon-boron composite oxide layer 3-5 / 176.56nm (materials are the same as 3-1), TiO 2 Layer 3-6 / 107.6nm, silicon-boron composite oxide layer 3-7 / 162.18nm (materials are the same as 3-1), TiO 2 Layer 3-8 / 95.87nm, silicon-boron composite oxide layer 3-9 / 150.64nm (material is the same as 3-1), ITO layer 3-10 / 105nm, silicon-boron composite oxide layer 3-11 / 138.42nm (material Same as 3-1), ITO layer 3-12 / 95.18nm, silicon-boron composite ...

Embodiment 2

[0101] An anti-reflection and anti-near-infrared laser resin lens, which includes: a resin lens substrate 1 (MR-8); a hardened layer 2 (Z117) / 2.6-3 μm; an anti-reflection layer 3 including: a silicon-boron composite oxide layer 3-1 (where SiO 2 and B 2 o 3 Mole percent: 80% SiO 2 , 20%B 2 o 3 ; Entrust Changzhou Zhanchi Photoelectric Technology Co., Ltd. to develop and produce, the material model is BL20) / 24.2nm, ITO layer 3-2 / 27.51nm, silicon boron composite oxide layer 3-3 / 9.18nm (material is the same as 3- 1), TiO 2 Layer 3-4 / 73.78nm, silicon-boron composite oxide layer 3-5 / 176.56nm (materials are the same as 3-1), TiO 2 Layer 3-6 / 107.6nm, silicon-boron composite oxide layer 3-7 / 162.18nm (materials are the same as 3-1), TiO 2 Layer 3-8 / 95.87nm; silicon-boron composite oxide layer 3-9 / 150.64nm (material is the same as 3-1), ITO layer 3-10 / 105nm, silicon-boron composite oxide layer 3-11 / 138.42nm (material Same as 3-1), ITO layer 3-12 / 95.18nm, silicon boron composite o...

Embodiment 3

[0103] An anti-reflection and anti-near-infrared laser resin lens, which includes: a resin lens substrate 1 (MR-8); a hardened layer 2 (Z117) / 2.6-3 μm; an anti-reflection layer 3 including: a silicon-boron composite oxide layer 3-1 (where SiO 2 and B 2 o 3 Mole percent: 92% SiO 2 , 8% B 2 o 3 ; Entrust Changzhou Zhanchi Photoelectric Technology Co., Ltd. to develop and produce, the material model is BL08) / 24.2nm, ITO layer 3-2 / 33.56nm, silicon boron composite oxide layer 3-3 / 7.82nm (material is the same as 3- 1), TiO 2 Layer 3-4 / 63.68nm, silicon-boron composite oxide layer 3-5 / 162.29nm (materials are the same as 3-1), TiO 2 Layer 3-6 / 98.07nm, silicon-boron composite oxide layer 3-7 / 145.87nm (materials are the same as 3-1), TiO 2 Layer 3-8 / 102.7nm; silicon-boron composite oxide layer 3-9 / 164.78nm (materials are the same as 3-1), TiO 2 Layer 3-10 / 115.2nm, silicon-boron composite oxide layer 3-11 / 170.82nm (materials are the same as 3-1), ITO layer 3-12 / 133.04nm, silicon-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com