Method and device for detecting yield of injection molding products and electronic equipment

A technology for injection molding and detection methods, applied in neural learning methods, biological neural network models, image data processing, etc., can solve problems such as inability to measure and inspect products, poor injection molding product manufacturing process, and improve scoring accuracy. degree, avoiding the effect of unstable scoring standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

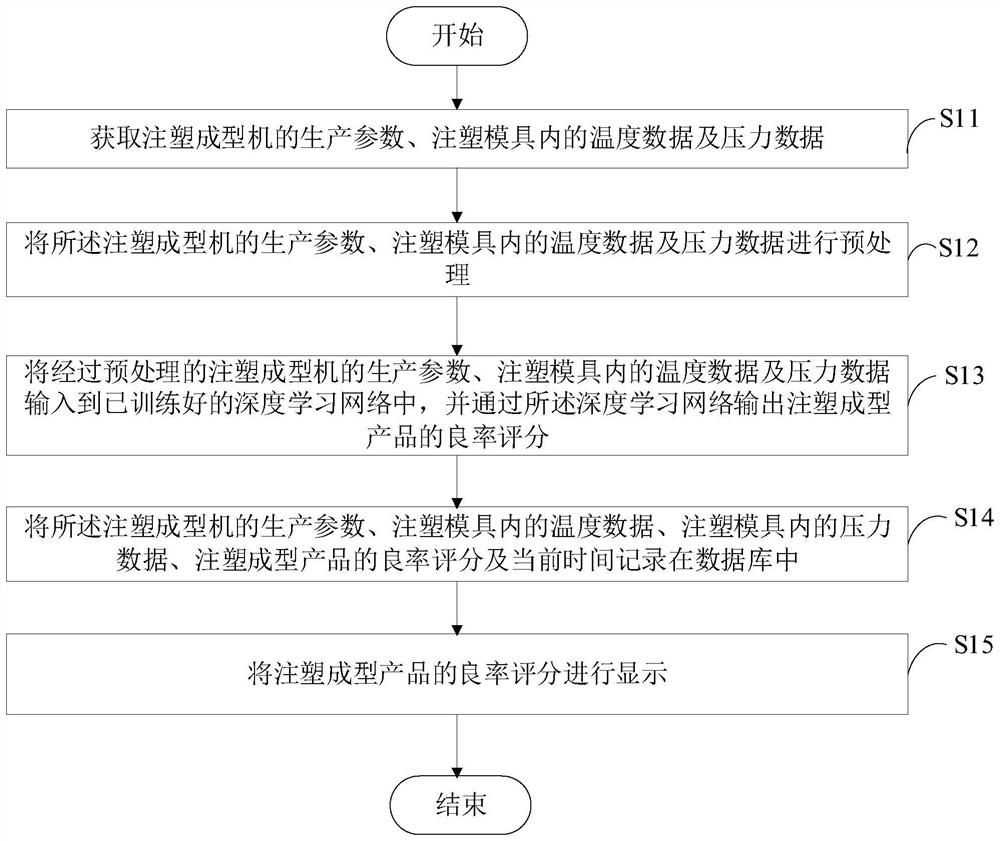

[0050] figure 1 It is a flow chart of the detection method for the yield rate of injection molded products in one embodiment of the present invention. According to different requirements, the order of the steps in the flowchart can be changed, and some steps can be omitted.

[0051] refer to figure 1 As shown, the detection method of the injection molding product yield specifically includes the following steps:

[0052] Step S11, obtaining the production parameters of the injection molding machine, temperature data and pressure data in the injection mold.

[0053] In this embodiment, the injection molding machine is used for injection molding the product to be injection molded. The number of the injection molding machines includes multiple, and the multiple injection molding machines are networked to form a molding machine network. In one embodiment, a plurality of the injection molding machines can be connected together by cables to form the molding machine network. In ano...

Embodiment 2

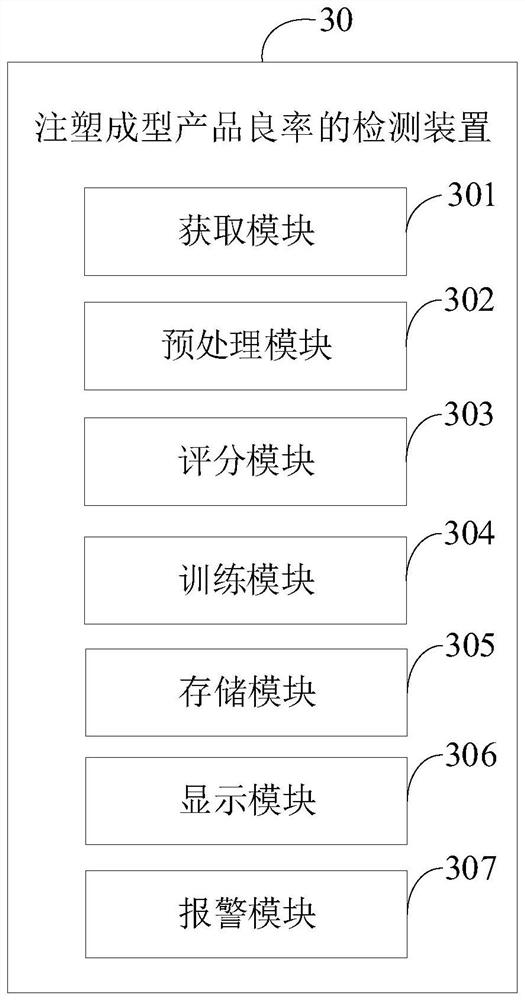

[0068] figure 2 It is a structural diagram of a detection device 30 for the yield rate of injection molded products in an embodiment of the present invention.

[0069] In some embodiments, the detection device 30 for the yield rate of the injection molded product runs in an electronic device. The inspection device 30 for the yield rate of injection molded products may include a plurality of functional modules composed of program code segments. The program codes of each program segment in the injection molding product yield detection device 30 can be stored in a memory, and executed by at least one processor to perform the injection molding product yield detection function.

[0070] In this embodiment, the detection device 30 for the yield rate of injection molded products can be divided into multiple functional modules according to the functions it performs. refer to figure 2 As shown, the injection molding product yield detection device 30 may include an acquisition modu...

Embodiment 3

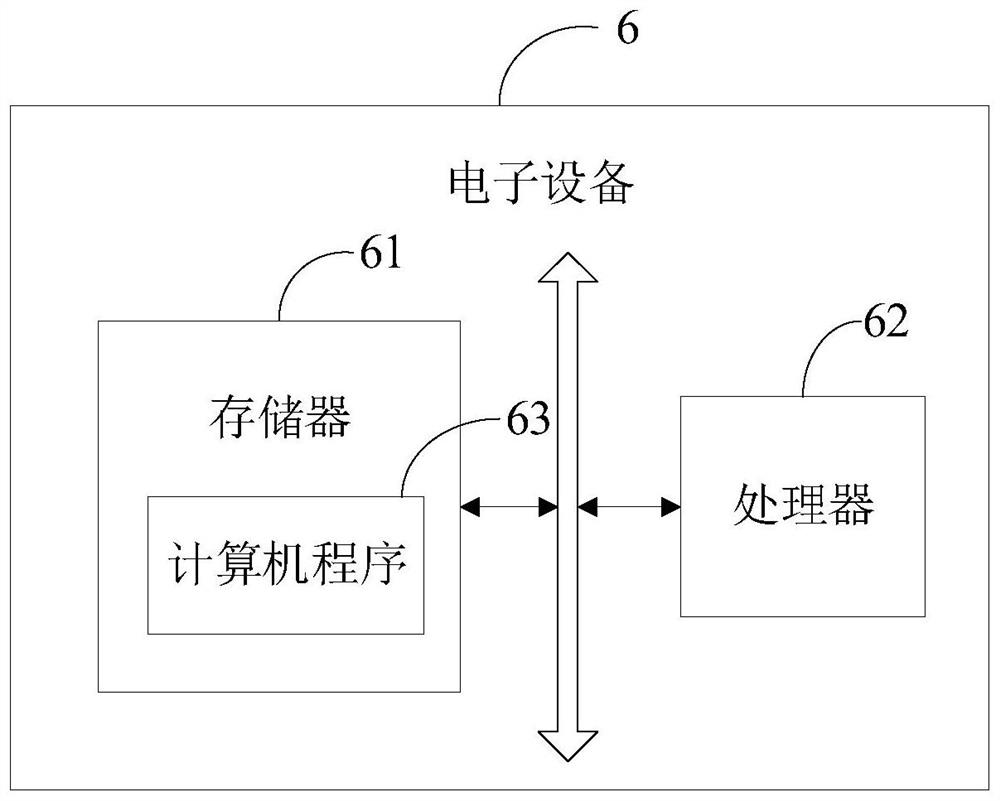

[0087] image 3 It is a schematic diagram of the electronic device 6 in an embodiment of the present invention.

[0088] The electronic device 6 includes a memory 61 , a processor 62 and a computer program 63 stored in the memory 61 and executable on the processor 62 . When the processor 62 executes the computer program 63, the steps in the embodiment of the method for detecting the yield of injection molded products are realized, for example figure 1 Steps S11 to S15 are shown. Alternatively, when the processor 62 executes the computer program 63, it realizes the functions of each module / unit in the embodiment of the detection device for the yield rate of injection molded products, for example figure 2 Modules 301-307 in.

[0089] Exemplarily, the computer program 63 can be divided into one or more modules / units, and the one or more modules / units are stored in the memory 61 and executed by the processor 62 to complete this invention. The one or more modules / units may be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com