A high-efficiency and low-loss corn threshing combined operation machine

A combined working machine and corn threshing technology, applied in threshing equipment, agricultural machinery and implements, agriculture, etc., can solve the problems of corn kernel damage, low effective core breaking rate, and great weather influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

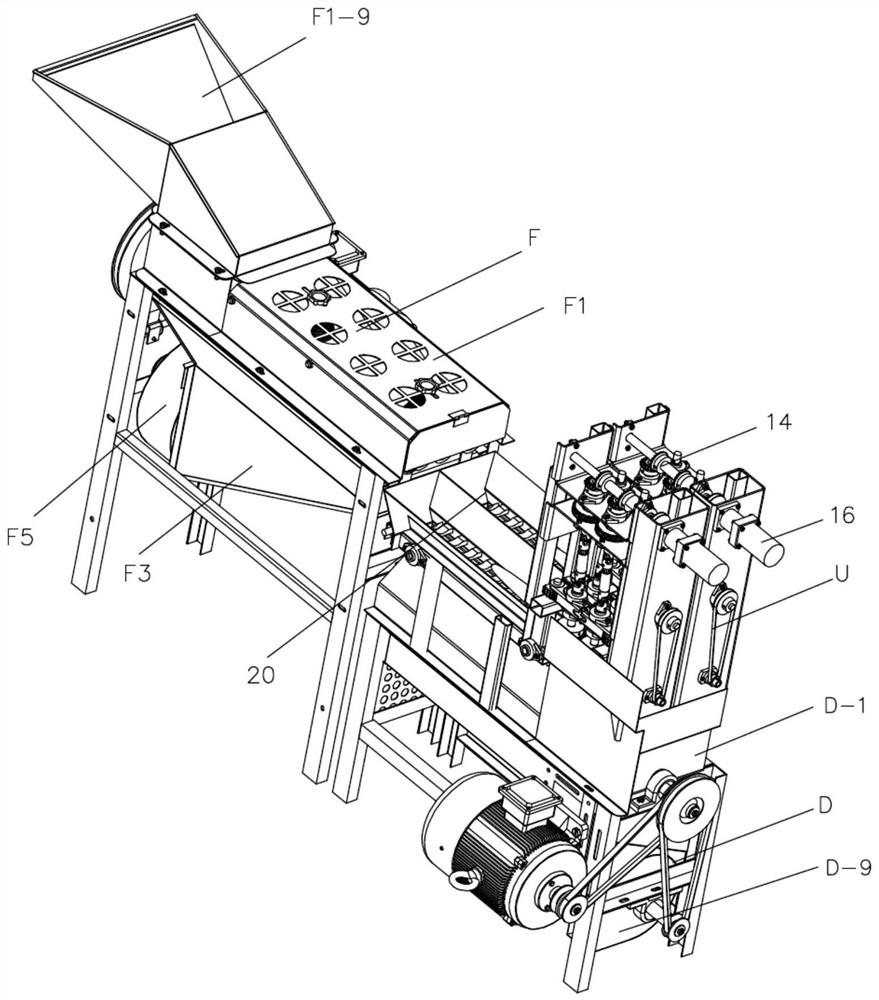

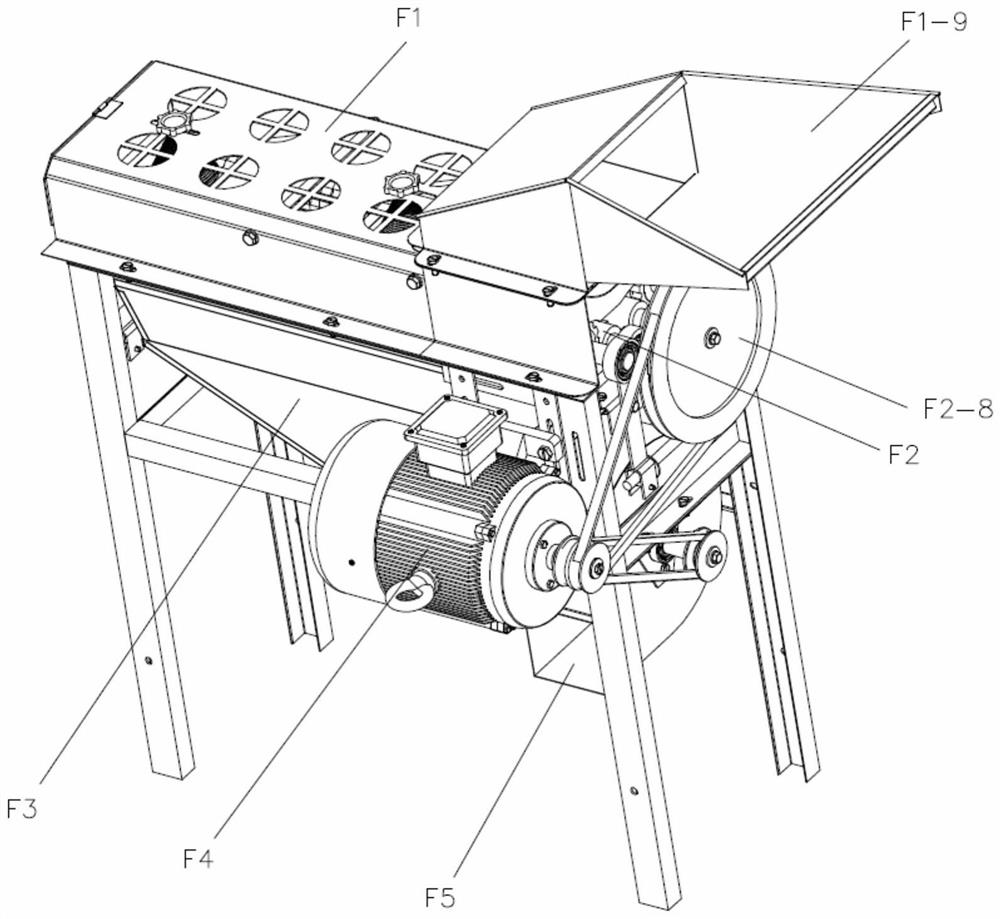

[0038] The basic composition of the high-efficiency and low-loss corn threshing combined operation machine in this embodiment is as follows: figure 1 As shown, it includes a peeling mechanism F, a broken core mechanism U whose output end is connected to its input end through a conveying trough 20, and a threshing mechanism D located below the broken core mechanism U.

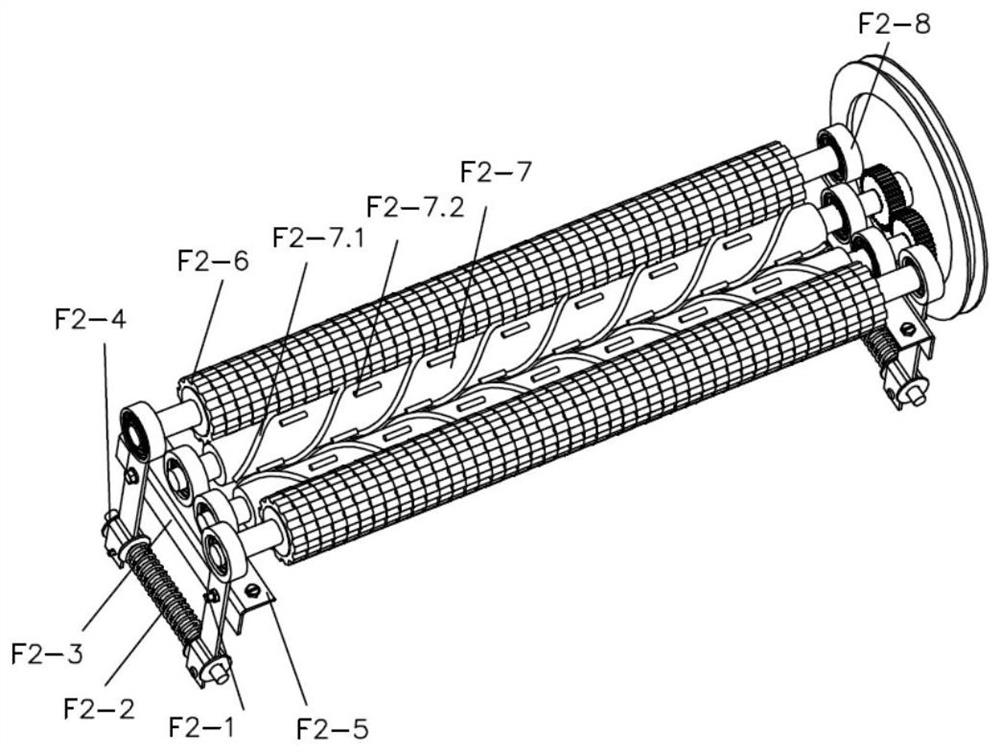

[0039] Peeling mechanism F such as figure 2 As shown, it includes an upper cover assembly F1 that is installed on the frame and has a feeding port F1-2 at one end. Feeding hopper F1-9 is housed on the feeding port F1-2. The upper cover assembly F1 as Figure 5 and Figure 7 As shown, the surface of the upper cover plate F1-1 forming the door-shaped cross-section passage distributes observation holes F1-5 at intervals, and its lower surface is hinged at one end of the oblique pressure plate F1-6 through the pin shaft F1-3, (pin shaft F1 -3 is supported on the left and right side plates of the upper cover ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com