Deuterium gas recycling device

A deuterium gas and installation platform technology, applied in the field of deuterium gas recovery and utilization devices, can solve the problems of slow deuterium reaction speed, incomplete reaction, and environmental pollution, and achieve the effect of increasing effect, simple structure, and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings.

[0029] This embodiment provides a deuterated gas recovery and utilization device, which is simple to facilitate the use of the mixed gas after use, and it is convenient for the gas circulation flow in the tank to ensure the sufficient filtration of the gas different depth in the mixing process. To increase the quality of the gas, it is easy to use.

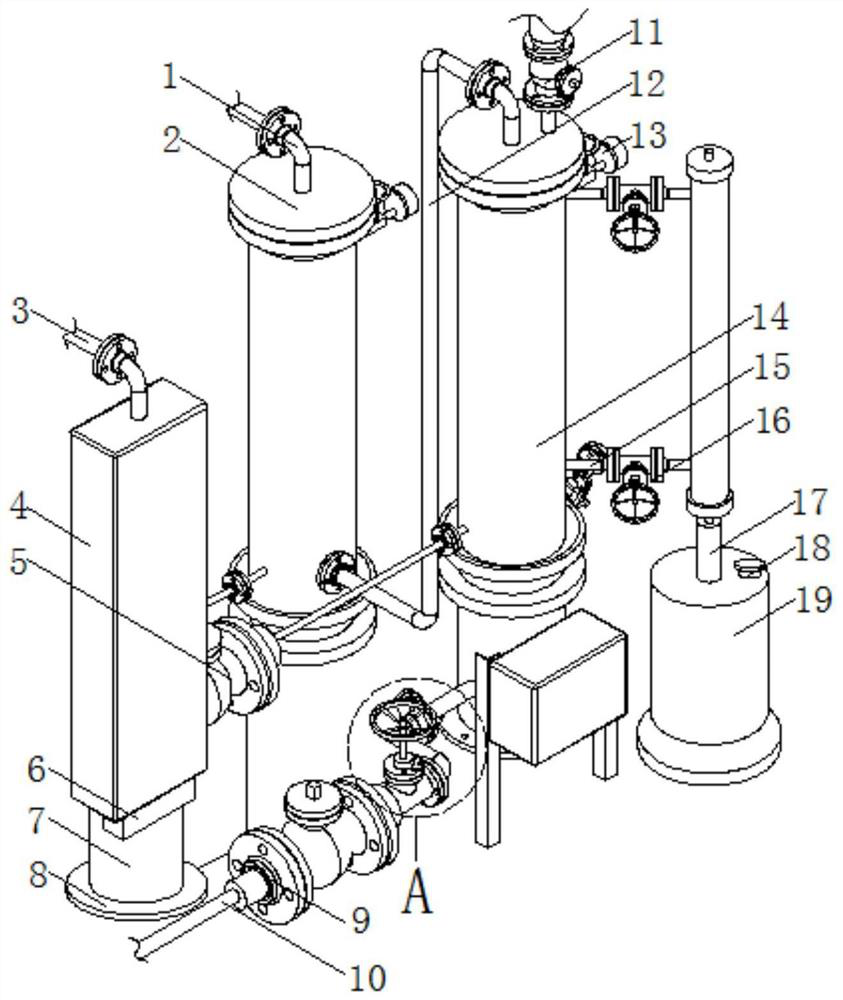

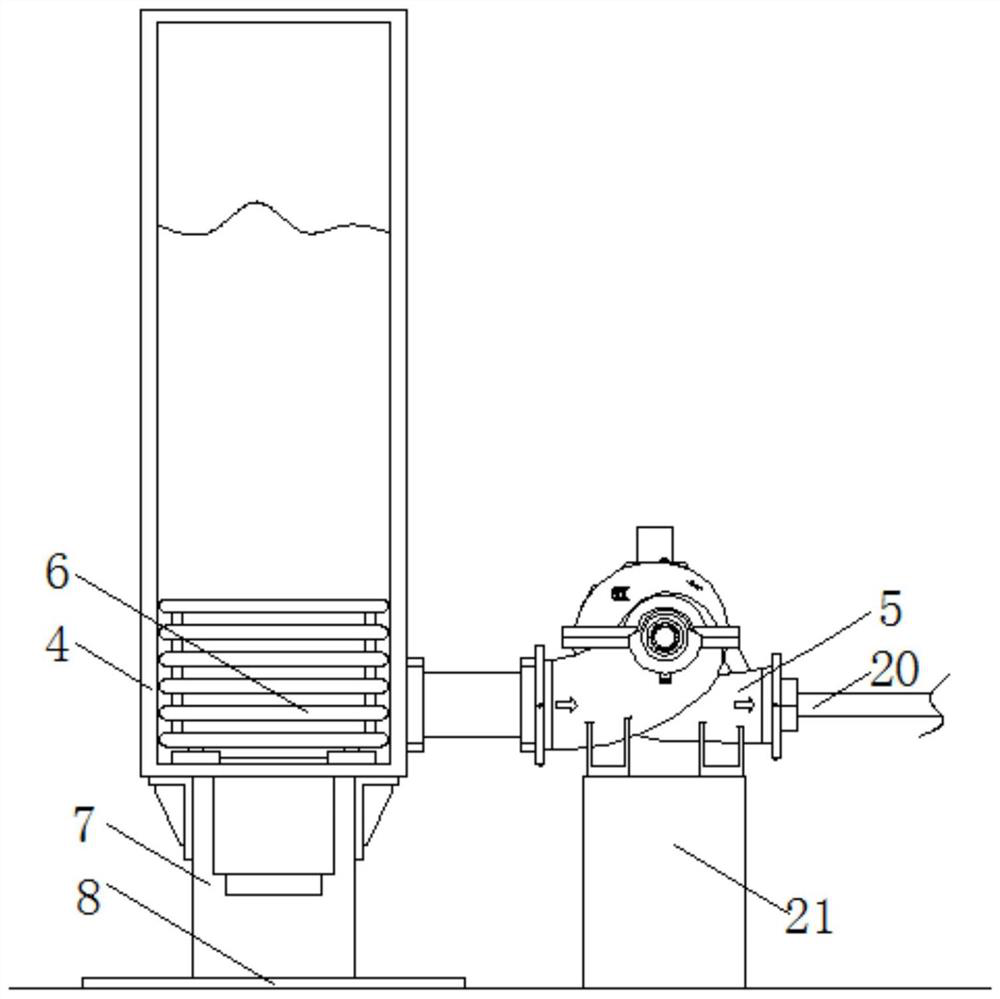

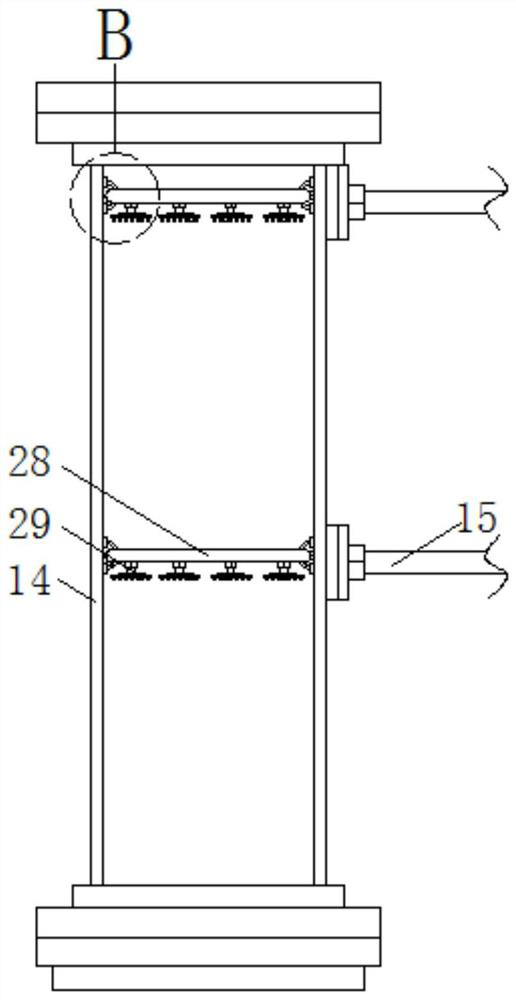

[0030] Such as figure 1 As shown, the 氘 气 recovery method includes: filter can 2, a cooling tank 4, a refrigerator 6, a first base 7, a first bottom plate 8, a spray tank 14, a reflow mechanism, and a water supply mechanism;

[0031] The lower end of the first base 7 is supported on the ground or a specific mounting platform by the first bottom plate 8, and the upper end is mounted, the cooling tank 4 is attached, and the refrigerator 6 is mounted in the inside of the cooling tank 4, and the top is mounted to discharge the tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com