Light-driven shape-programmable MXene composite hydrogel driver and preparation method thereof

A hydrogel-actuated and light-driven technology, applied in the field of intelligent soft robots, achieves the effects of achieving experimental conditions, superior light energy-mechanical energy conversion capabilities, and simple experimental methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

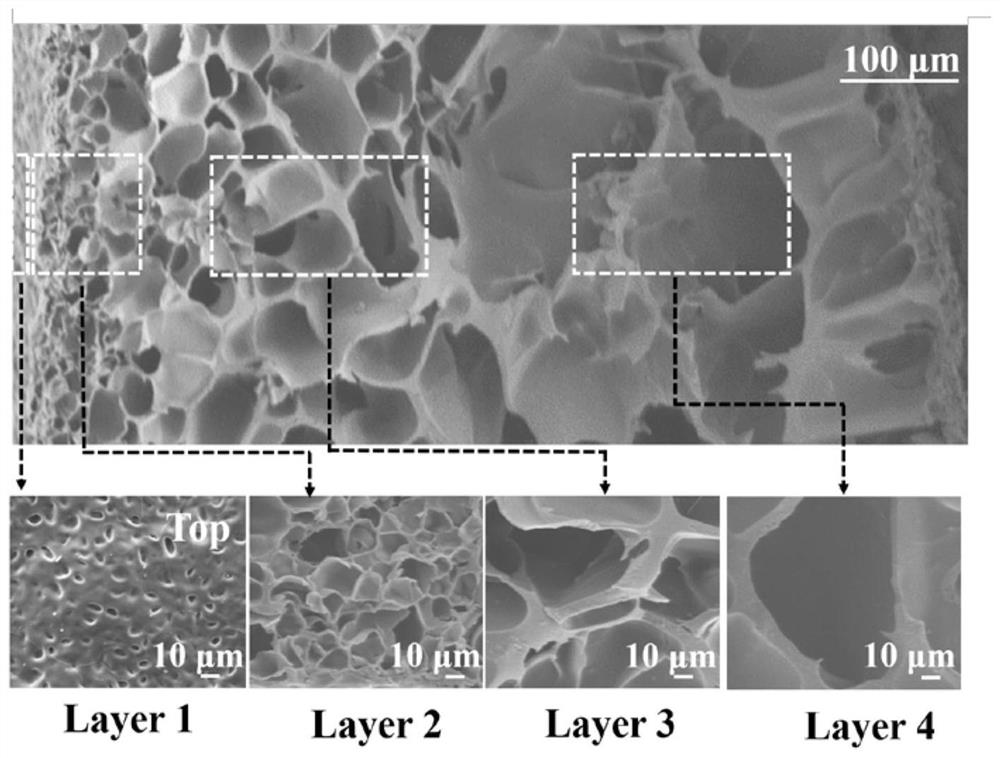

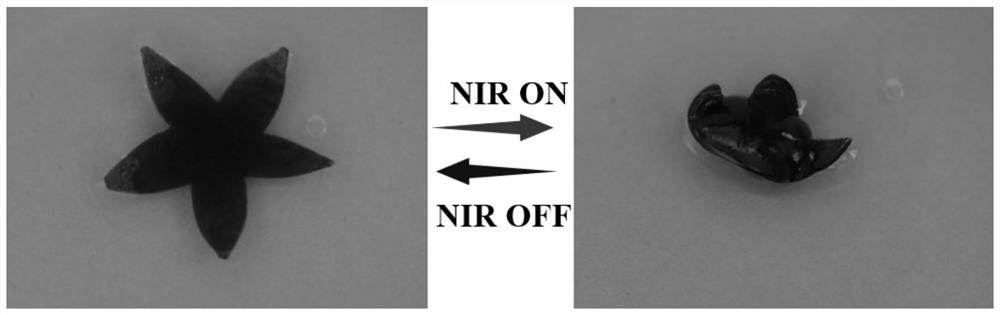

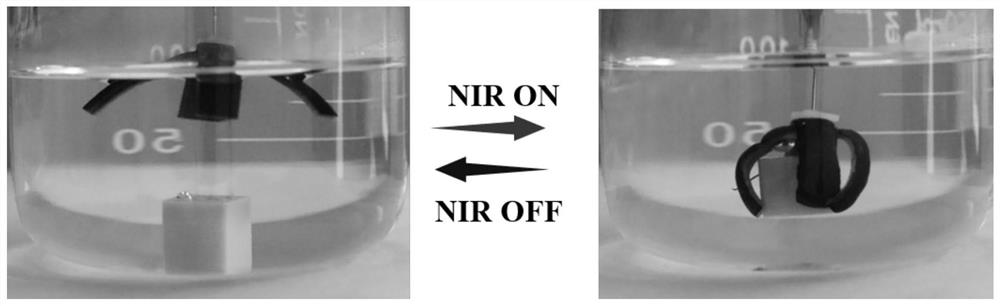

Embodiment 1

[0037] Poly(N-isopropylacrylamide) (PNIPAm) precursor solution consists of 400 mg NIPAm monomer, 20 mg N,N'-methylbisacrylamide, 5 μL of photoinitiator 2-hydroxy-2-methylpropiophenone (Darocur 1173), 10mg of MXene nano-monomer mixed with 1mL deionized water. Subsequently, the above poly(N-isopropylacrylamide) (PNIPAm) precursor solution was injected into a glass mold (40mL × 40mL × 1mL), in the structure of the glass mold, both the top and bottom layers were provided with ITO transparent electrodes, the height Silicone pads are set in the direction to insulate the top layer and the bottom layer, that is, the upper and lower ITO glasses are used to connect the positive and negative electrodes of the external power supply respectively, so as to realize the poly(N-isopropylacrylamide) (PNIPAm) in the glass mold. ) The electric field effect of the precursor solution. Apply 2V mm between top ITO glass and bottom ITO glass -1 DC electric field for 10min, after removing the electri...

Embodiment 2

[0040] Poly(N-isopropylacrylamide) (PNIPAm) precursor solution consists of 400 mg NIPAm monomer, 20 mg N,N'-methylbisacrylamide, 5 μL of photoinitiator 2-hydroxy-2-methylpropiophenone (Darocur 1173), 10mg of MXene nano-monomer mixed with 1mL deionized water. Using the reaction vessel in Example 1, in the structure of the glass mold, ITO transparent electrodes are provided on the top layer and the bottom layer, and silica gel pads are arranged on the height direction to insulate between the top layer and the bottom layer, that is, using two pieces of ITO glass up and down The positive and negative poles of the external power supply are respectively connected to realize the electric field action on the poly(N-isopropylacrylamide) (PNIPAm) precursor solution in the glass mould. The poly(N-isopropylacrylamide) (PNIPAm) precursor solution was injected into the mold assembled by ITO glass and silica gel through a syringe, and 2V mm was applied. -1 DC electric field for 10min, after...

Embodiment 3

[0042] The poly(N-isopropylacrylamide) (PNIPAm) precursor solution was composed of 400 mg NIPAm monomer, 20 mg N,N,N'-methylbisacrylamide, 5 μL of photoinitiator 2-hydroxy-2-methylpropane Benzophenone (Darocur 1173), 10 mg of MXene nanomonomer and 1 mL of deionized water were mixed. Using the reaction vessel in Example 1, in the structure of the glass mold, ITO transparent electrodes are provided on the top layer and the bottom layer, and silica gel pads are arranged on the height direction to insulate between the top layer and the bottom layer, that is, using two pieces of ITO glass up and down The positive and negative poles of the external power supply are respectively connected to realize the electric field action on the poly(N-isopropylacrylamide) (PNIPAm) precursor solution in the glass mould. The poly(N-isopropylacrylamide) (PNIPAm) precursor solution was injected into the mold assembled by ITO glass and silica gel through a syringe, and 2V mm was applied. -1 DC electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com