Mismatch-free II-type superlattice structure based on antimony shutter switch and preparation method

A shutter switch, superlattice technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, ion implantation plating, etc., can solve problems such as complex process, and achieve the effect of simplifying process steps, reducing complexity, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

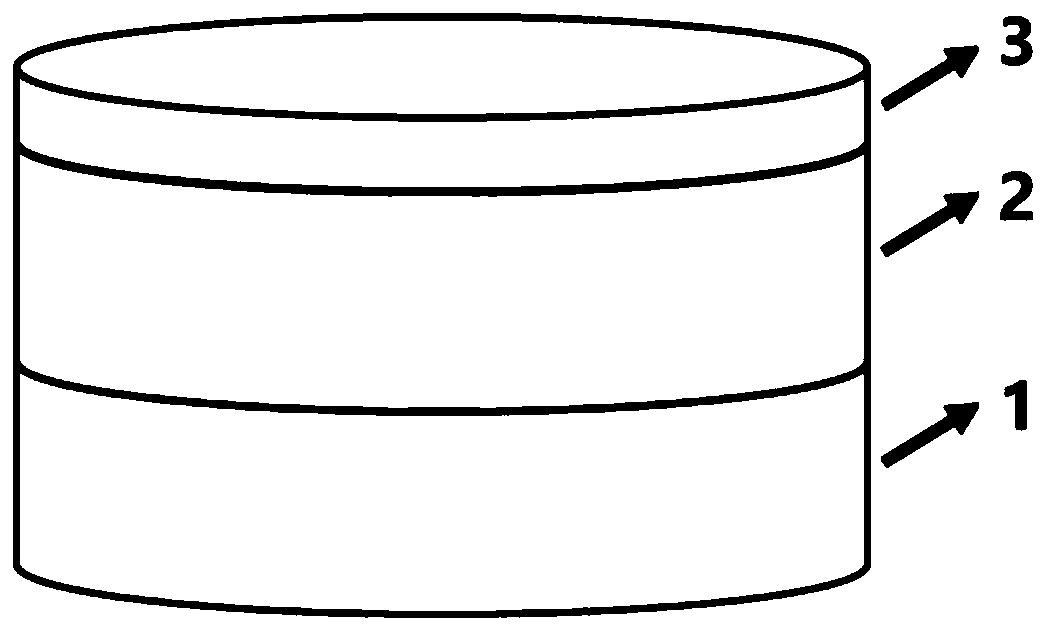

[0022] According to the content of the invention, we have prepared a type II superlattice material, the specific structure of which is:

[0023] The thickness of GaSb layer 1 is 1.05nm;

[0024] The thickness of the InAs layer 2 is 2.45nm;

[0025] InAs x Sb 1-x Layer 3 has a thickness of 0.3 nm and a composition x of 0.20;

[0026] Its specific preparation method is:

[0027] 1) The GaSb substrate is heated up to the deoxidation temperature, and the oxide layer on the surface is removed under the protection of the Sb beam. The deoxidation temperature is 560 °C, and the Sb beam is 2×10 -6 Torr;

[0028] 2) Cool down the GaSb substrate to the type II superlattice growth temperature of 395°C;

[0029] 3) Set the As / In and Sb / Ga growth beam current ratios to 4 and 5, respectively;

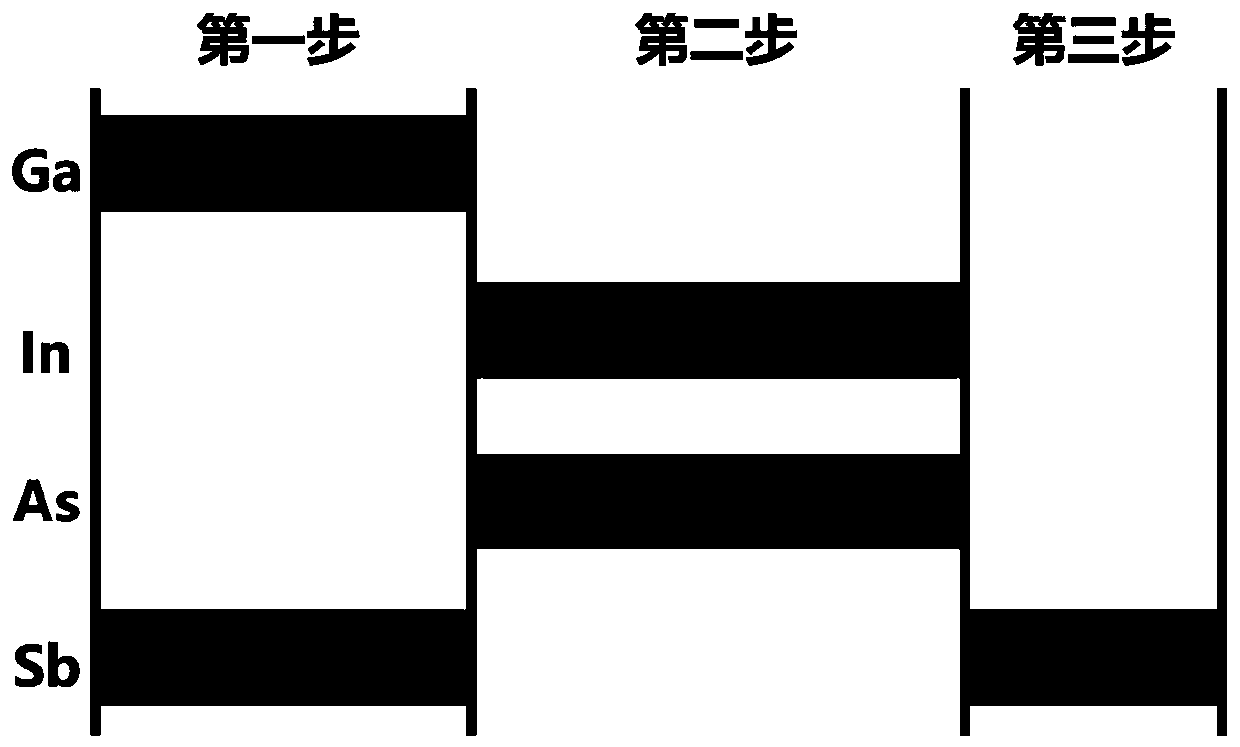

[0030] 4) Using molecular beam epitaxy to grow InAs / GaSb II superlattice on the GaSb substrate, the first step is to open the Ga and Sb shutters to epitaxially GaSb layer 1, and the second step...

Embodiment 2

[0032] According to the content of the invention, we have prepared a type II superlattice material, the specific structure of which is:

[0033] GaSb layer 1 has a thickness of 2.1 nm;

[0034] The thickness of the InAs layer 2 is 1.2nm;

[0035] InAs x Sb 1-x The thickness of layer 3 is 0.3nm, the component x is 0.39, and the Sb infiltration time is 1s;

[0036] Its specific preparation method is:

[0037] 1) The GaSb substrate is heated up to the deoxidation temperature, and the oxide layer on the surface is removed under the protection of the Sb beam. The deoxidation temperature is 570°C, and the Sb beam is 2×10 -6 Torr;

[0038] 2) Cool down the GaSb substrate to the type II superlattice growth temperature of 400°C;

[0039] 3) Set the As / In and Sb / Ga growth beam current ratios to 4 and 5, respectively;

[0040] 4) Using molecular beam epitaxy to grow InAs / GaSb II superlattice on the GaSb substrate, the first step is to open the Ga and Sb shutters to epitaxially GaS...

Embodiment 3

[0042] According to the content of the invention, we have prepared the third type II superlattice material, the specific structure of which is:

[0043] The thickness of the GaSb layer 1 is 2.4nm;

[0044] The thickness of the InAs layer 2 is 3.0nm;

[0045] InAs x Sb 1-x Layer 3 has a thickness of 0.3 nm and a composition x of 0.02;

[0046] Its specific preparation method is:

[0047] 1) The GaSb substrate is heated up to the deoxidation temperature, and the oxide layer on the surface is removed under the protection of the Sb beam. The deoxidation temperature is 580°C, and the Sb beam is 2×10 -6 Torr;

[0048] 2) Cool down the GaSb substrate to the type II superlattice growth temperature of 405°C;

[0049] 3) Set the As / In and Sb / Ga growth beam current ratios to 4 and 5, respectively;

[0050] 4) Using molecular beam epitaxy to grow InAs / GaSb II superlattice on the GaSb substrate, the first step is to open the Ga and Sb shutters to epitaxially GaSb layer 1, and the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com