Preparation method and application of gradient hydrogel soft drive

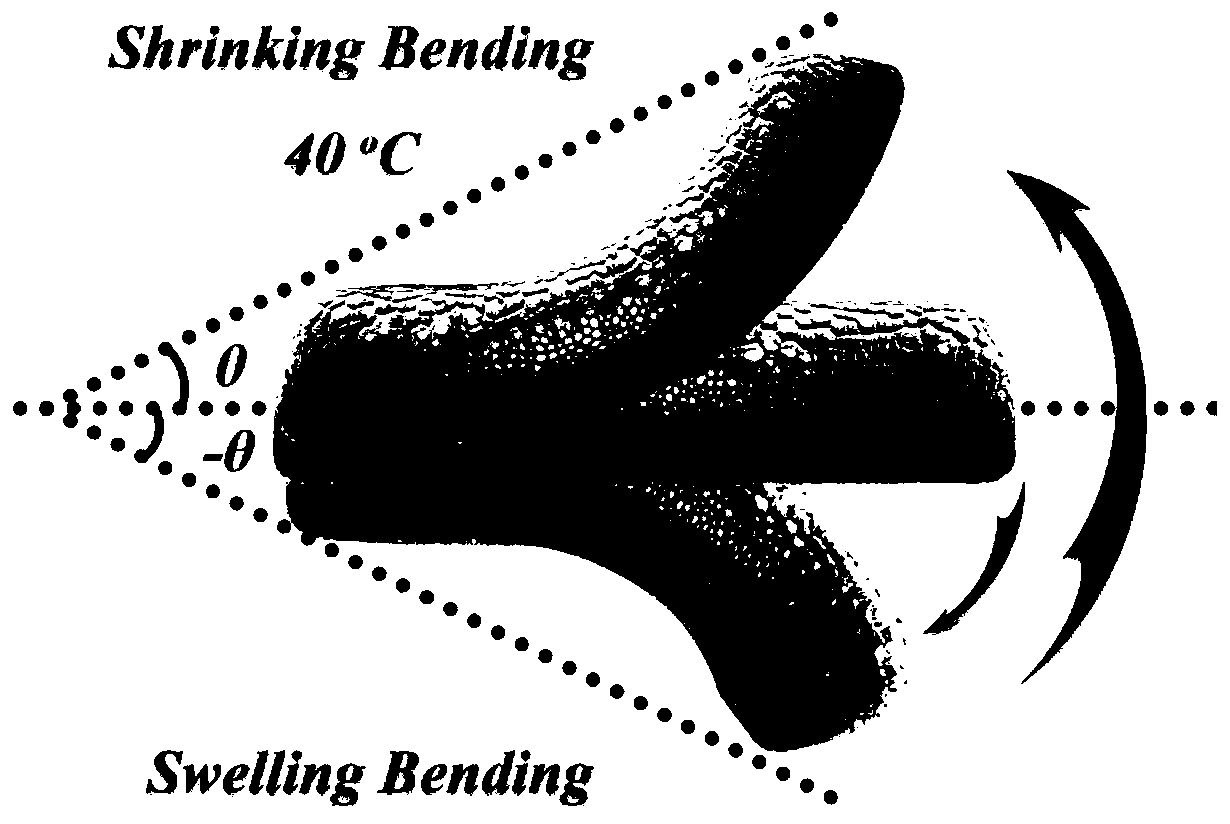

A hydrogel and actuator technology, applied in the field of preparation of gradient hydrogel soft actuators, can solve the problems of lack of "smart" response performance, interface defects of double-layer structure hydrogel soft actuators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

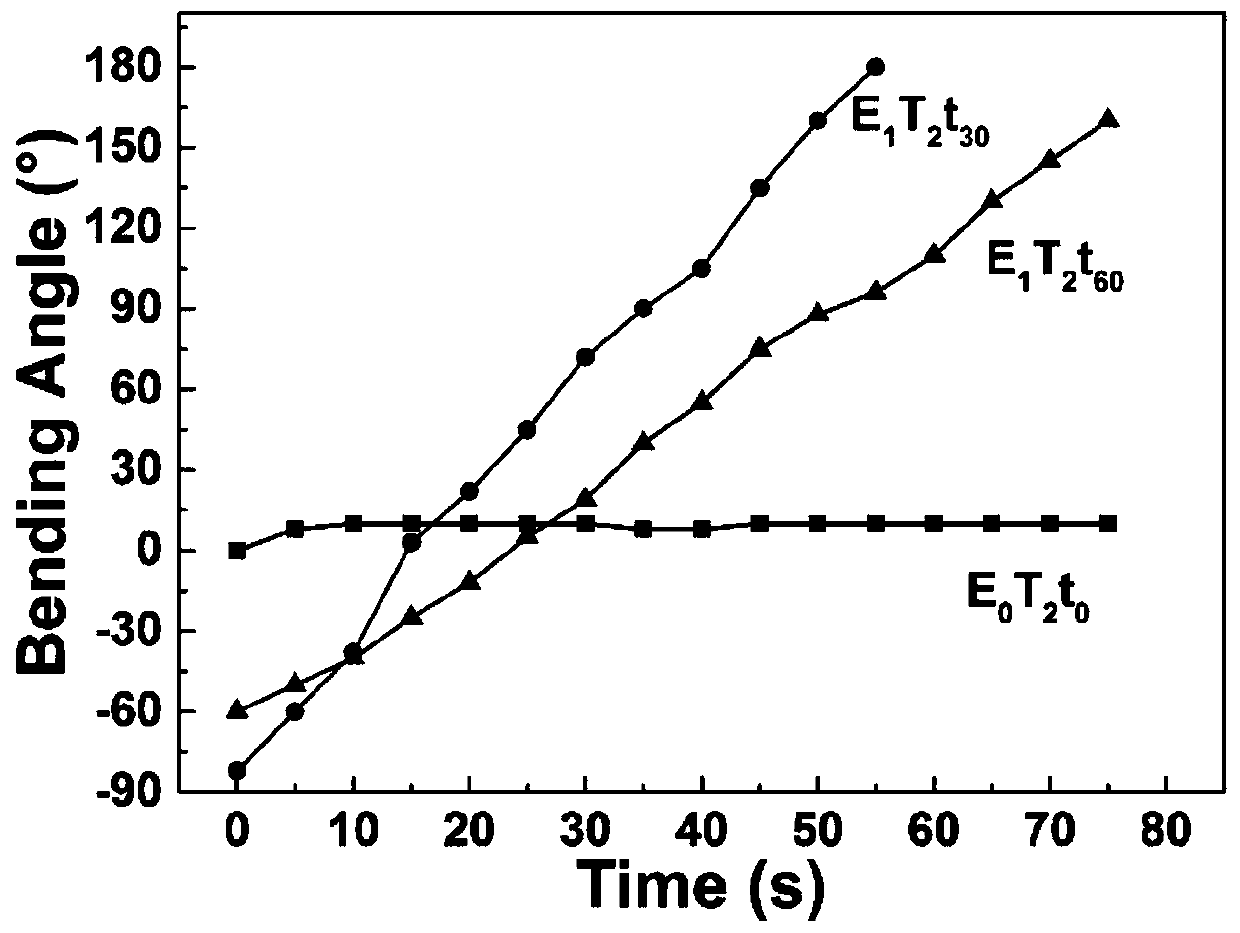

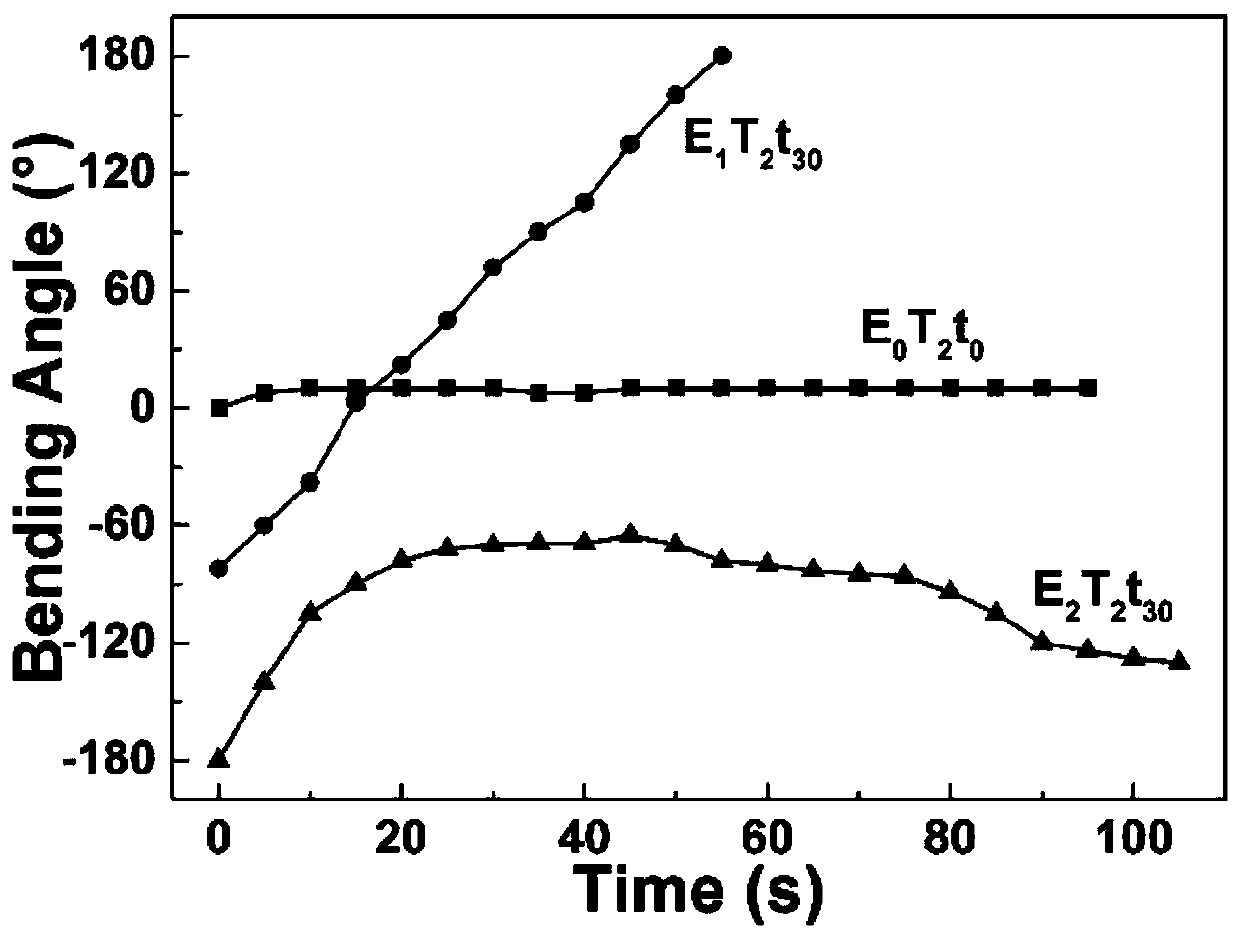

Embodiment 1

[0033] 0.565g NIPAM monomer, 1.468g TCNCs suspension (0.77wt%), 0.5g initiator KPS solution (1.08wt%), 0.25g crosslinker BIS solution (0.75wt%), 3μL Accelerator TEMED is mixed, and deionized water is added until the total mass of the mixed solution is 5 g. The mixture was vortexed for 3 minutes, then ultrasonicated in an ice-water bath for 5 minutes to obtain a uniformly dispersed mixture, and then vacuumed for 5 minutes. Pour the mixed solution into a conductive mold, apply a DC electric field, the electric field strength is 1V / mm, and the induction time is 30min, then place the mold at 20°C to initiate polymerization / crosslinking, take it out after 24h and immerse it in deionized water to remove unreacted of small molecules. The sample is named E 1 T 2 t 30 .

Embodiment 23

[0035] 0.565g NIPAM monomer, 1.468g TCNCs suspension (0.77wt%), 0.5g initiator KPS solution (1.08wt%), 0.25g crosslinker BIS solution (0.75wt%), 3μL Accelerator TEMED is mixed, and deionized water is added until the total mass of the mixed solution is 5 g. The mixture was vortexed for 3 minutes, then ultrasonicated in an ice-water bath for 5 minutes to obtain a uniformly dispersed mixture, and then vacuumed for 5 minutes. Pour the mixed solution into a conductive mold, apply a DC electric field, the electric field strength is 1V / mm, and the induction time is 60min, then place the mold at 20°C to initiate polymerization / crosslinking, take it out after 24h and immerse it in deionized water to remove unreacted of small molecules. The sample is named E 1 T 2 t 60 .

Embodiment 3

[0037] 0.565g NIPAM monomer, 1.468g TCNCs suspension (0.77wt%), 0.5g initiator KPS solution (1.08wt%), 0.25g crosslinker BIS solution (0.75wt%), 3μL Accelerator TEMED is mixed, and deionized water is added until the total mass of the mixed solution is 5 g. The mixture was vortexed for 3 minutes, then ultrasonicated in an ice-water bath for 5 minutes to obtain a uniformly dispersed mixture, and then vacuumed for 5 minutes. Pour the mixed solution into a conductive mold, apply a DC electric field, the electric field strength is 2V / mm, and the induction time is 30min, then place the mold at 20°C to initiate polymerization / crosslinking, take it out after 24h and immerse it in deionized water to remove unreacted of small molecules. The sample is named E 2 T 2 t 30 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com