A kind of automatic clearing system and clearing method for sampling hole of converter vaporization flue

A vaporization flue and sampling hole technology, which is applied in the direction of manufacturing converters, improving process efficiency, improving energy efficiency, etc., can solve the problems of harsh working conditions and environment of vaporization flue, clogging of sampling holes of detection devices, and difficulty in stable and reliable cleaning. , to achieve the effect of reducing maintenance, extending service life and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0029] It should be noted that the structures, proportions, sizes, etc. shown in this specification are only used to cooperate with the contents disclosed in the specification, so as to be understood and read by those who are familiar with this technology, and are not used to limit the conditions that the present invention can be implemented. , any modification of the structure, the change of the proportional relationship or the adjustment of the size, without affecting the effect that the present invention can produce and the purpose that can be achieved, should still fall within the scope that the technical content disclosed in the present invention can cover .

[0030] At the same time, the terms such as "up", "down", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and clarity, and are not used to limit this specification. The implementable scope of the invention, and the change or adjustment of the relative relat...

Embodiment 1

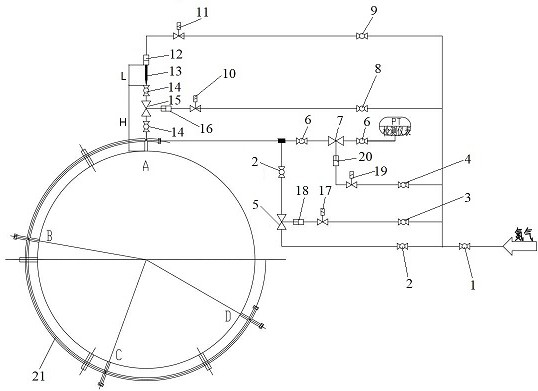

[0032] like figure 1As shown in the figure, the present invention discloses an automatic blockage removal system for the sampling hole of the converter vaporization flue, which includes a purging pipeline, a purging driving pipeline, a sampling driving pipeline, a sampling pipeline, a sampling hole control valve group, a needle driving pipeline, and a valve group. One end of the driving pipeline, the poking needle 13 and the control assembly, the purging pipeline, the purging driving pipeline, the sampling driving pipeline, the poking needle driving pipeline and the valve group driving pipeline are respectively connected with the nitrogen input pipeline, and the other end of the purging pipeline is connected with the sampling pipeline. The other end of the purging drive pipeline is connected to the purging pipeline, the other end of the sampling drive pipeline is connected to the sampling pipeline, the other end of the needle drive pipeline is connected to the needle 13, the ot...

Embodiment 2

[0036] preferably, as figure 1 As shown, the sampling pipeline includes two sampling manual valves 6 and one sampling pneumatic valve 7, the two ends of the sampling pneumatic valve 7 are respectively connected to the sampling manual valve 6 through pipelines, and the other end of the one sampling manual valve 6 is connected to the converter vaporization through pipelines. The flue sampling hole and the other end of the other sampling manual valve 6 are connected to the PT detection instrument through the pipeline.

[0037] preferably, as figure 1 As shown, the sampling drive pipeline includes a sampling drive manual valve 4, a sampling drive solenoid valve 19 and a sampling drive cylinder 20, wherein one end of the sampling drive manual valve 4 is connected to the nitrogen main valve 1 of the nitrogen input pipeline through a pipeline, and the sampling drive manual valve 4 The other end is connected to the sampling drive solenoid valve 19 through the pipeline, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com