Production method for preparing high-end wood products through dewatering process

A technology of wood products and production methods, which is applied in the field of wood product processing, can solve the problems affecting the dehydration effect, achieve the effect of ensuring the effect of heating dehydration, reducing the possibility of wrinkles due to dehydration, and improving the effect of dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

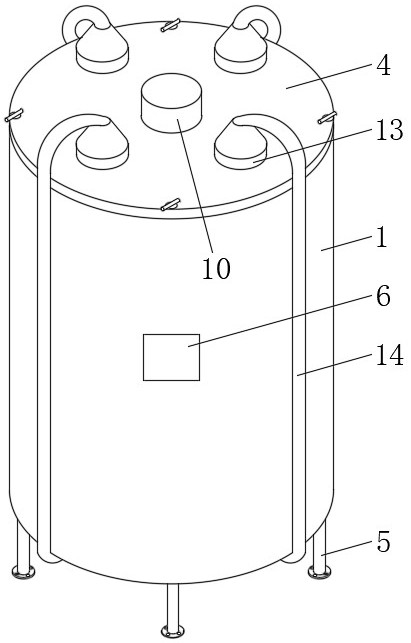

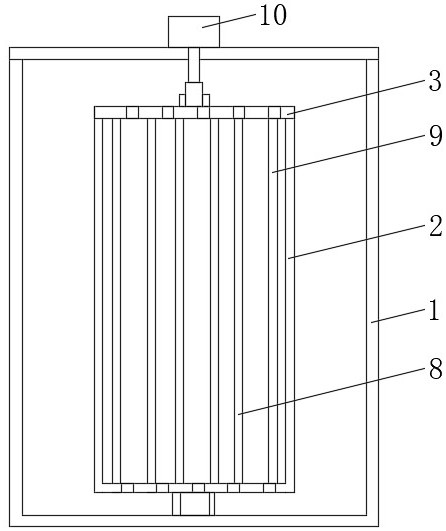

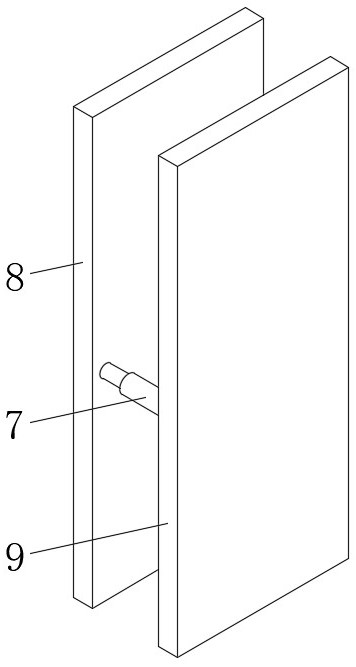

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings of the present invention.

[0020] A production method for preparing wood products by dehydration process, specifically: (1), clean materials: clean the wood products that need to be dehydrated, and remove dust and stains on the surface; (2), pre-dehydration: put wood into dehydration In the device, fix it between the movable plate and the fixed plate, cover the box cover, connect the barrel cover, turn on the ultrasonic heating to raise the temperature to 35°C, turn on the rotating motor at a constant temperature of 3000r / min and dry for 2 hours; (3), dehydration: open Rotate the motor and exhaust fan, adjust the ultrasonic heating parameters to raise the temperature to 60°C, the parameter of the rotating motor is the speed of 8000r / min, and the dehydration operation can be performed for 1-2h.

[0021] For de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com