Automobile turbocharger middle shell cooling hole unblocking and blocking testing device and method

A turbocharger and testing device technology, which is applied in the direction of measuring devices, machine/structural component testing, mechanical component testing, etc., can solve the problems of inconvenient testing of the middle shell and high labor intensity, and achieve reliable and stable product quality. The effect of reducing labor intensity and quick and clear results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

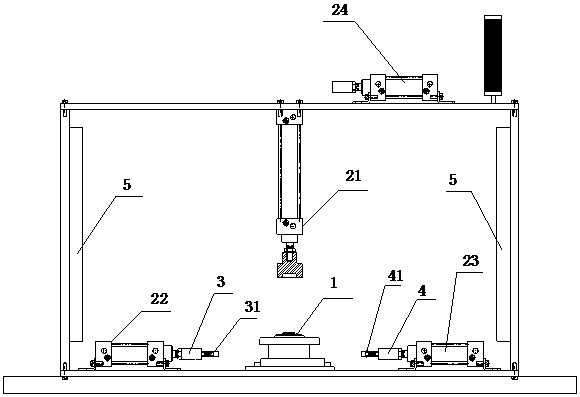

[0018] Such as figure 1 As shown, an automobile turbocharger intermediate shell cooling hole is blocked test device, including a rack, a workpiece clamping cylinder 21, an intake positioning head 3, an air positioning head 4, and a detecting cylinder 24, a rack set up for The mounting station of the mounting intermediate case 1 is fixed to the frame, and the car turbocharger intermediate case 1 is fixed to be detected; at least one intake is provided on the intake positioning head 3. Plug 31, the intake plug 31 is adapted to be connected to the cooling hole of the intermediate case 1, each intake blocker 31 is connected to the intake branch, and the intake branch is provided for controlling the intake branch tube. The air-off refiner 4 is provided on the air positioning head 4, which is adapted to connect to the cooling hole outlet of the intermediate case 1, and the air-proof plug 41 is connected to the air supply. The detecting cylinder 24 is in communication between the airflow...

Embodiment 2

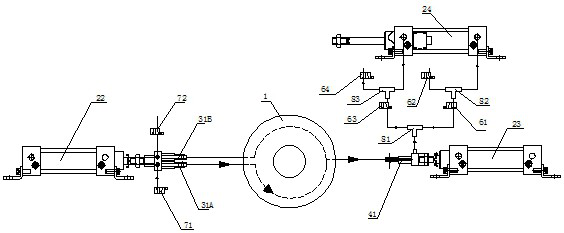

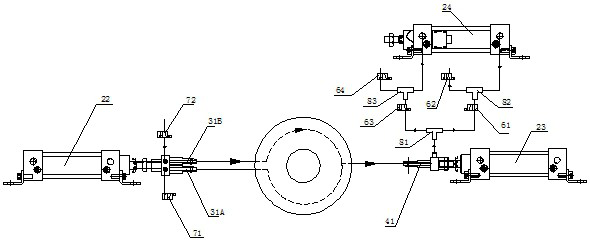

[0028] The intermediate case 1 of the binary and one cooling hole is swolched. Since the second is further out, the intermediate case 1 forms the first cooling inner hole and the second cooling inner hole; the corresponding, intake plug 31 For two, the first intake plug 31a and the second intake blocker 31b are respectively, the number of air-shaped plug 41 is one; the first intake blocker 31a blocks the first intake port, the second intake The plug 31b blocks the second intake port, the venting plug 41 blocks the air outlet; figure 2 As shown, the first cooling inner hole is blocked: the first intake solenoid valve 71, the first detecting solenoid valve 61, the fourth detecting solenoid valve 64 is applied, the second intake solenoid valve 72, the second detection solenoid valve 62. The third detection solenoid valve 63 is absent; the gas entering the first cooling inner hole passes through the air cylinder 24, the first detecting tube, and the second detecting tube enters the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com