Method for testing fragment penetration resistance and sealing performance of chemical defense and explosion-proof tank

A technology of sealing performance and testing method, which is applied in the testing of machine seals, testing of mechanical parts, testing of machine/structural parts, etc. The anti-fragment penetration and sealing performance test methods of explosion-proof tanks have achieved the effects of reliable test results, protection of people's lives and ecological environment safety, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

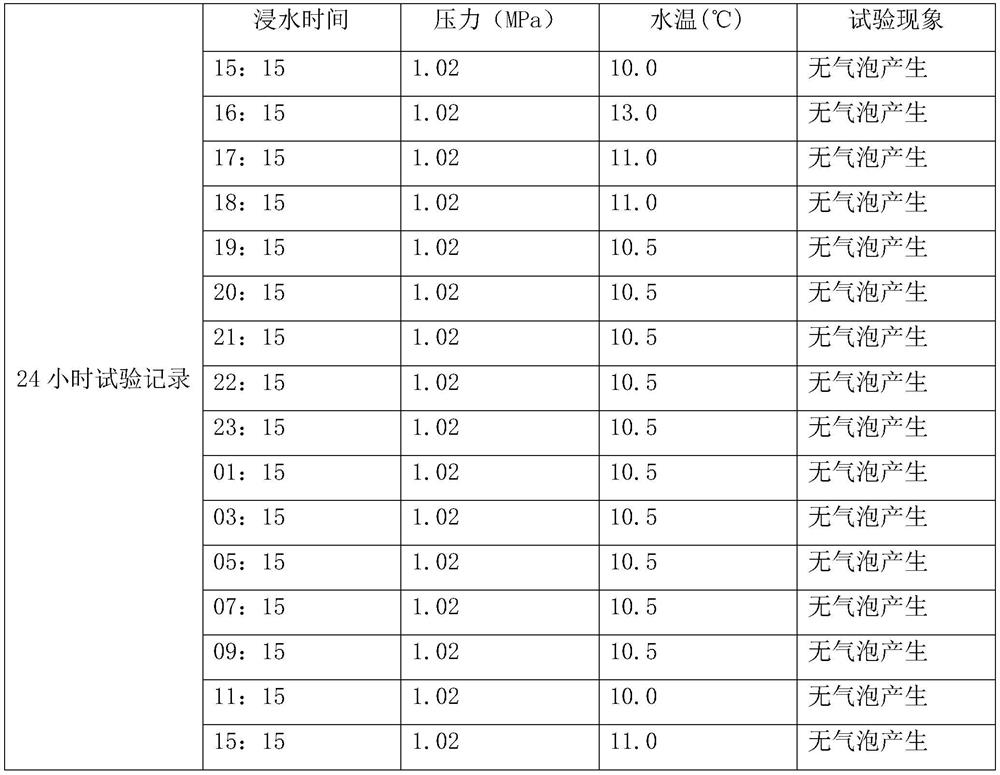

[0021] Embodiment 1, a method for testing the anti-fragment penetration and sealing performance of a chemical explosion-proof tank according to this embodiment, comprising the following steps:

[0022] 1) Static sealing performance appraisal

[0023] (1) Before the test, check that the pipeline connection is normal, inflate the chemical explosion-proof tank to the pressure gauge pressure value of 1.02MPa, test that there is no leakage at each interface of the pipeline, observe that the pressure gauge value does not change after rising from 0 to 1.02MPa, and release the chemical explosion-proof tank No leakage before entering the water tank;

[0024] ⑵Put the pressurized anti-chemical and explosion-proof tank into the water tank. After the chemical and explosion-proof tank is completely submerged in the water, the test personnel observe that there are no bubbles on the water surface;

[0025] (3) After observing that there are no bubbles on the water surface and no change in t...

Embodiment 2

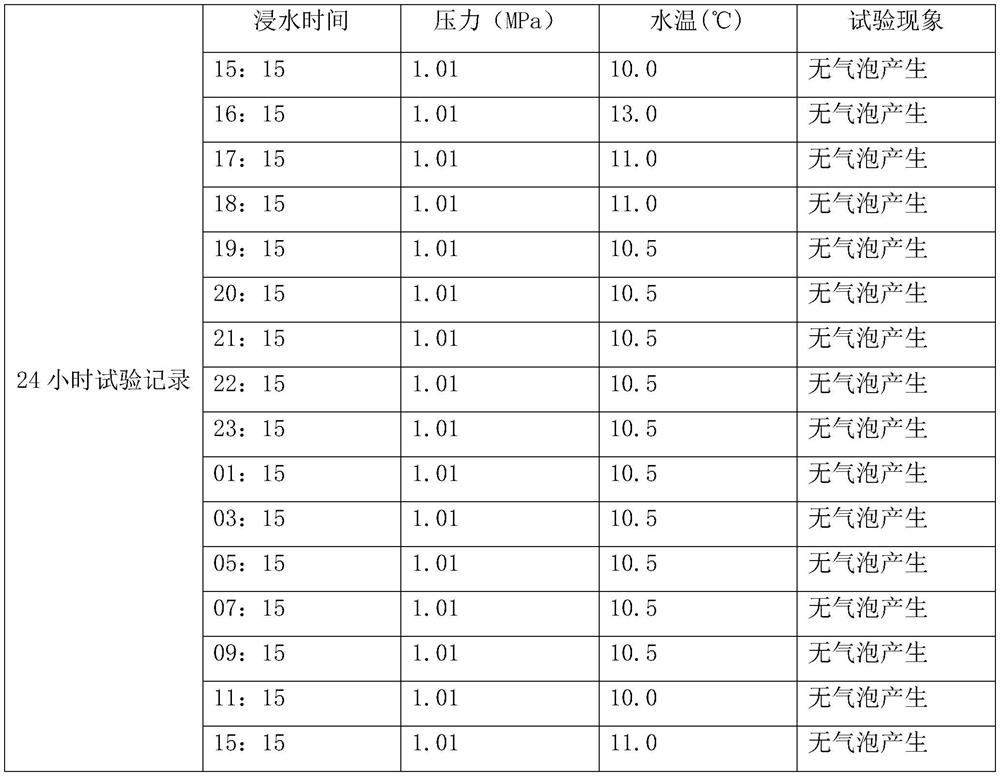

[0041] Embodiment 2, the specific steps of this embodiment are as follows:

[0042] 1) Static sealing performance appraisal

[0043] (1) Check that the pipeline connection is normal before the test, inflate the chemical explosion-proof tank to the pressure gauge pressure value of 1.01MPa, test that there is no leakage at each interface of the pipeline, and observe that the pressure gauge value does not change after rising from 0 to 1.01MPa to ensure the chemical explosion-proof tank No leakage before putting into the water tank;

[0044] (2) Put the pressurized anti-chemical and explosion-proof tank into the water tank, and after the chemical and explosion-proof tank is completely submerged in the water, the test personnel observe that there are no bubbles on the water surface;

[0045] (3) After observing that there are no bubbles on the water surface and no change in the value of the pressure gauge, keep it in its state for 24 hours. During this period, the test personnel o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com