Three-dimensional inward turning type air inlet flow field distortion suppression method based on RBF (Radial Basis Function) network

A technology of internally rotating inlet and RBF network, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve the problems of increased total pressure loss, reduced anti-backpressure ability of the inlet, and the area of the suction port. Large and other problems, to achieve the effect of reducing internal flow loss, improving comprehensive compression efficiency, and expanding effective circulation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

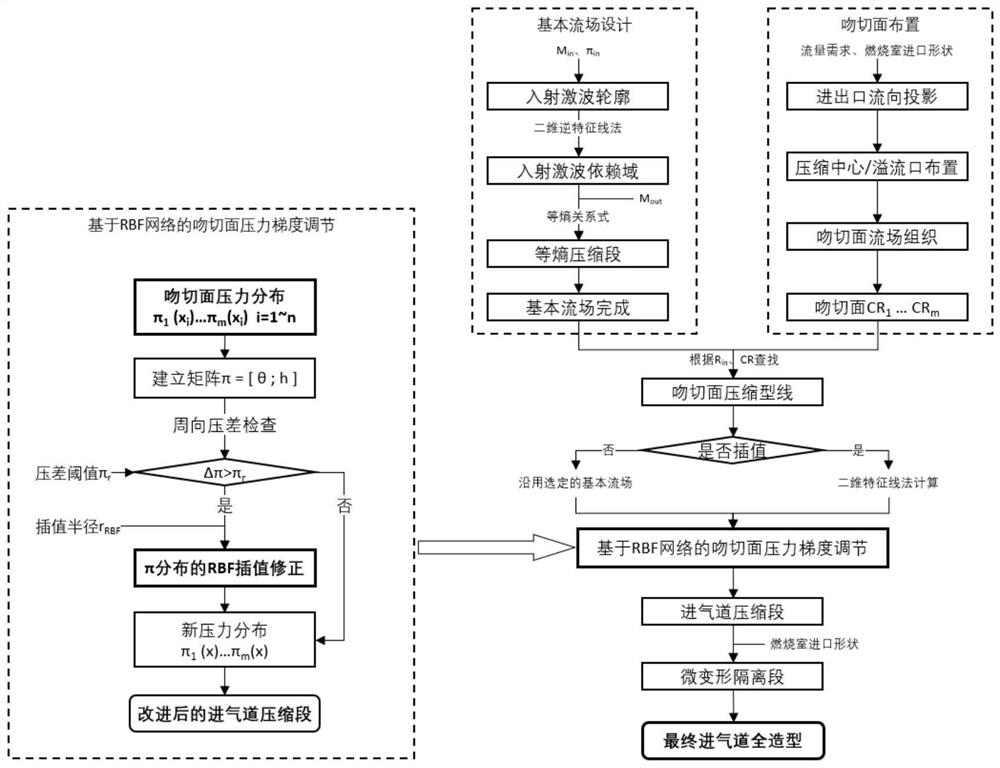

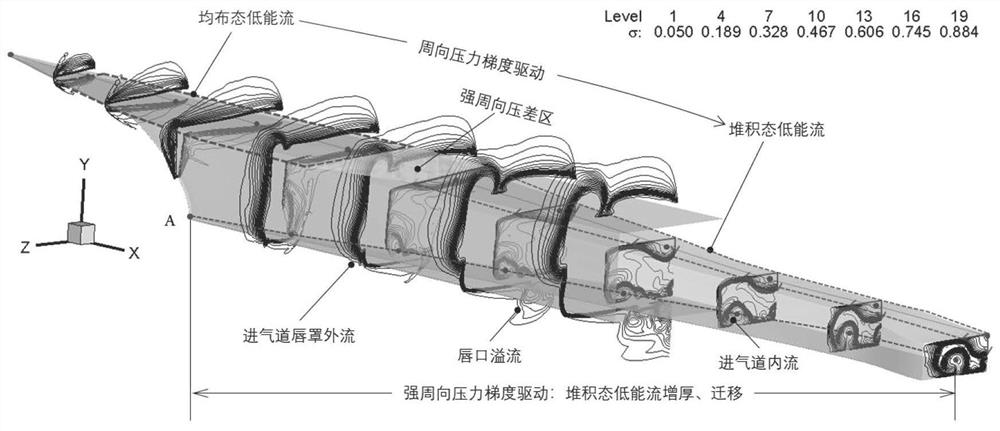

[0027] Example: such as figure 1 Shown is the flow chart of the RBF network-based method for suppressing the flow field distortion of the three-dimensional inward-turning inlet. Among them, the right side of the figure is the design process of a new three-dimensional inward-turning inlet with weak circumferential pressure difference, and the left side of the figure is based on The RBF network-based kiss section pressure adjustment process; and the RBF network-based three-dimensional inwardly turning inlet flow field distortion suppression method includes two processes: identification of low-energy flow zones and RBF network-based kiss section pressure adjustment;

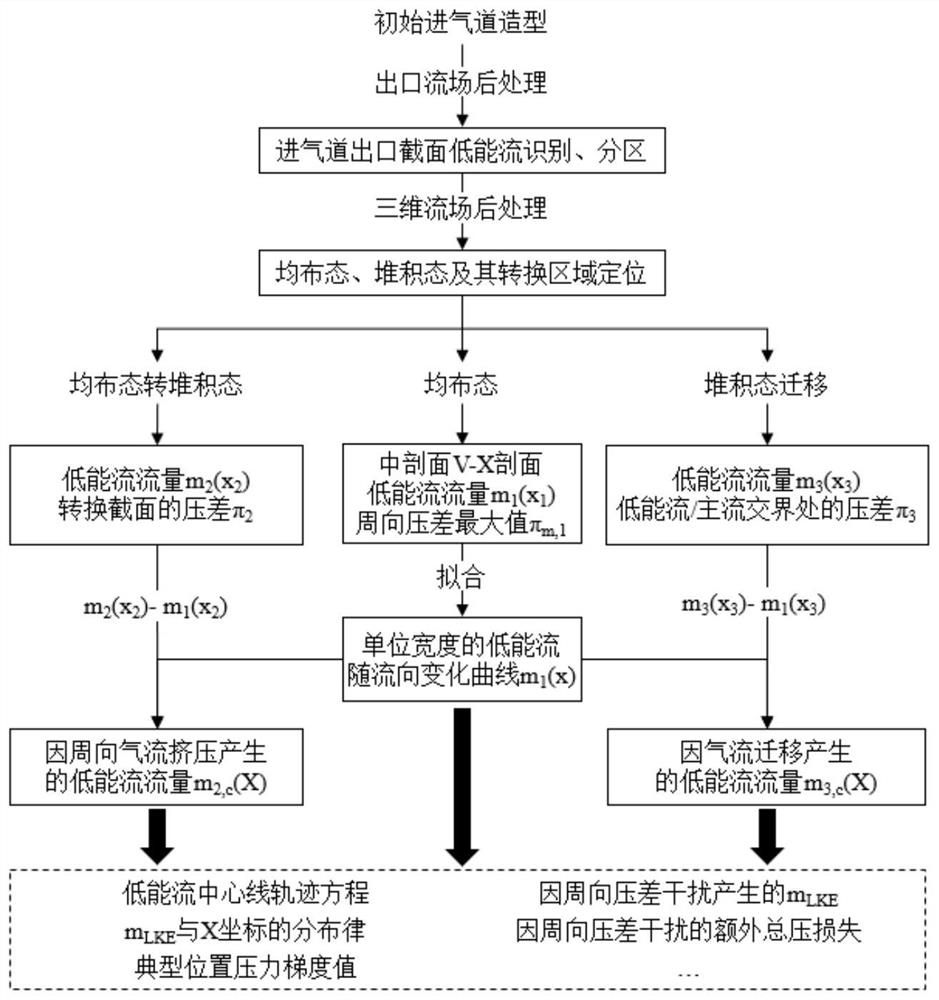

[0028] Such as figure 2 As shown, for the identification of low-energy flow zones, firstly, the shape of the inlet is preliminarily designed based on the principle of kiss-cut flow, and numerical simulation is carried out to obtain the internal flow field performance library of the inlet, and the flow field post-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com