Method for constructing full-stage creep model of polymer bonded composite material

A composite material and construction method technology, which is applied in the field of full-stage creep model construction of polymer bonded composite materials, can solve the problem of not considering the change of temperature and holding stress, etc., so that the experimental data is simple, feasible and achievable, and the complexity is reduced degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

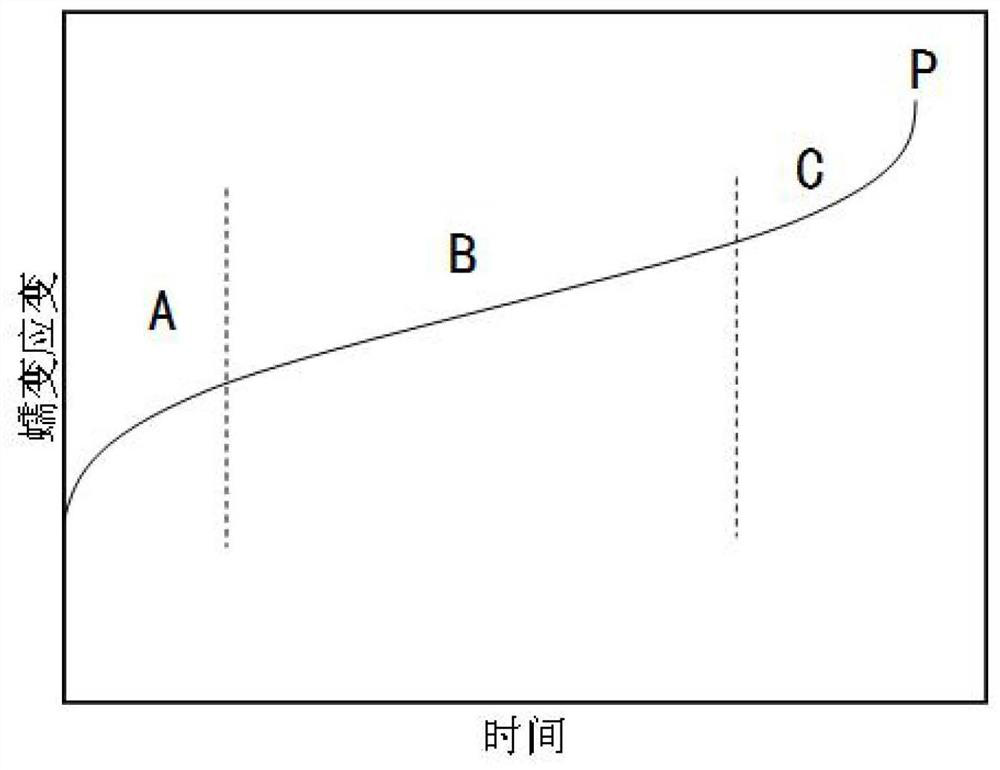

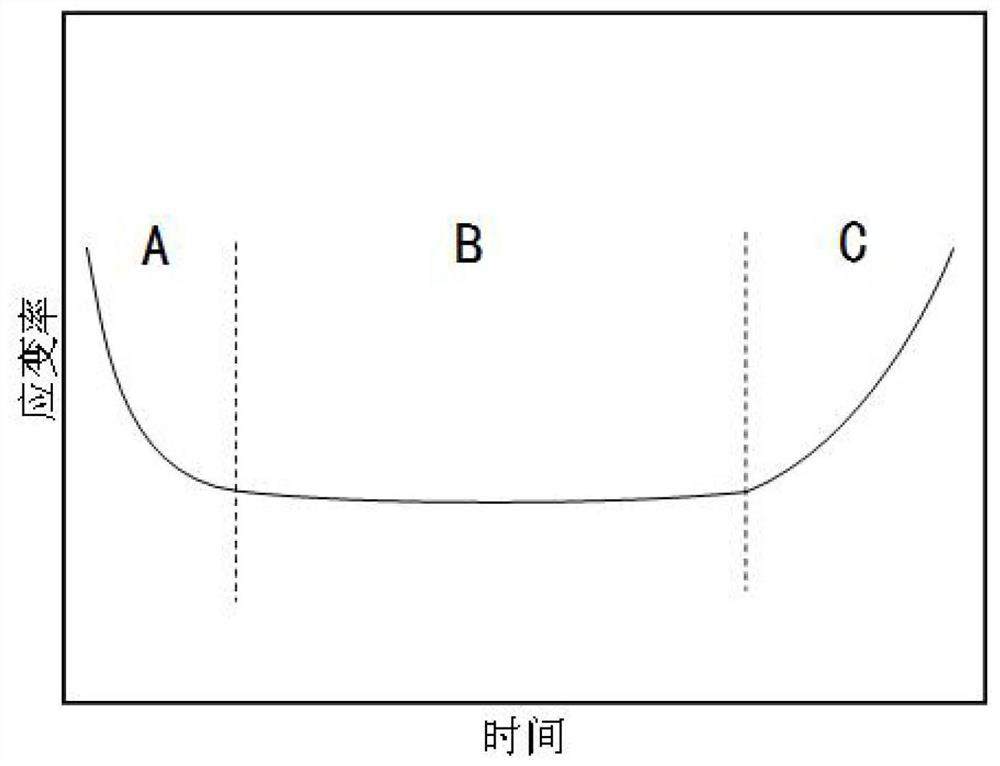

[0069] The present invention is a method for constructing a full-stage creep model of a polymer bonded composite material, considering the effects of temperature and maintaining stress, as shown in Figures 1 to 7, and the specific implementation steps are as follows:

[0070] In step 1, the creep data of samples of polymer bonded composite materials at different test temperatures are obtained as test data.

[0071] The test data can directly use historical test data, or can be obtained through actual tests. The test data obtained through the actual test is as follows: according to the actual engineering needs, research needs, and the number of samples in stock, select the test temperature, maintain the stress range, determine the test conditions within the temperature and maintain stress range, and set each test condition The number of samples of the polymer bonded composite material is kept in a temperature box for compression creep test to obtain the stress, strain and corre...

specific Embodiment 2

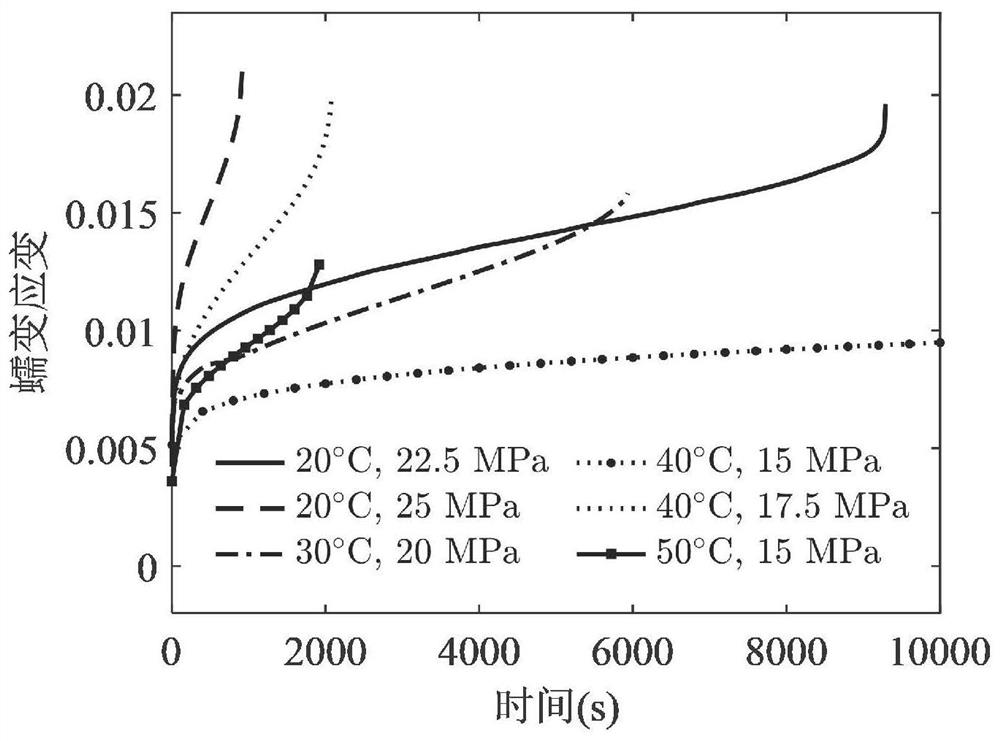

[0152] Using the creep data, the generality of the model constructed by the whole-stage creep model construction method of the polymer bonded composite material proposed by the present invention can be further verified. The specific test temperature and holding stress are shown in Table 3.

[0153] Corresponding creep data such as Figure 8 shown.

[0154] table 3

[0155]

[0156]

[0157] Using the data in the literature, based on the creep model of specific example 1, on the basis of not adjusting the model structure, only using new data to recalibrate the model parameters, using the operation method from step 2.1 to step 2.5, the creep can be obtained Variable model parameters, as shown in formula (49).

[0158]

[0159] Figure 9 (a)-9 (b) shows the comparison between the prediction results of the proposed model and the reference data, where the scattered points are third-party data, and the curve is the result of modeling using third-party data. The model describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com