Waste building material recycling machine

A technology of building materials and recycling machines, applied in cleaning methods and utensils, grain processing, chemical instruments and methods, etc., can solve problems such as time-consuming and labor-consuming, low production efficiency, hidden dangers to workers' health and safety, and save manpower , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

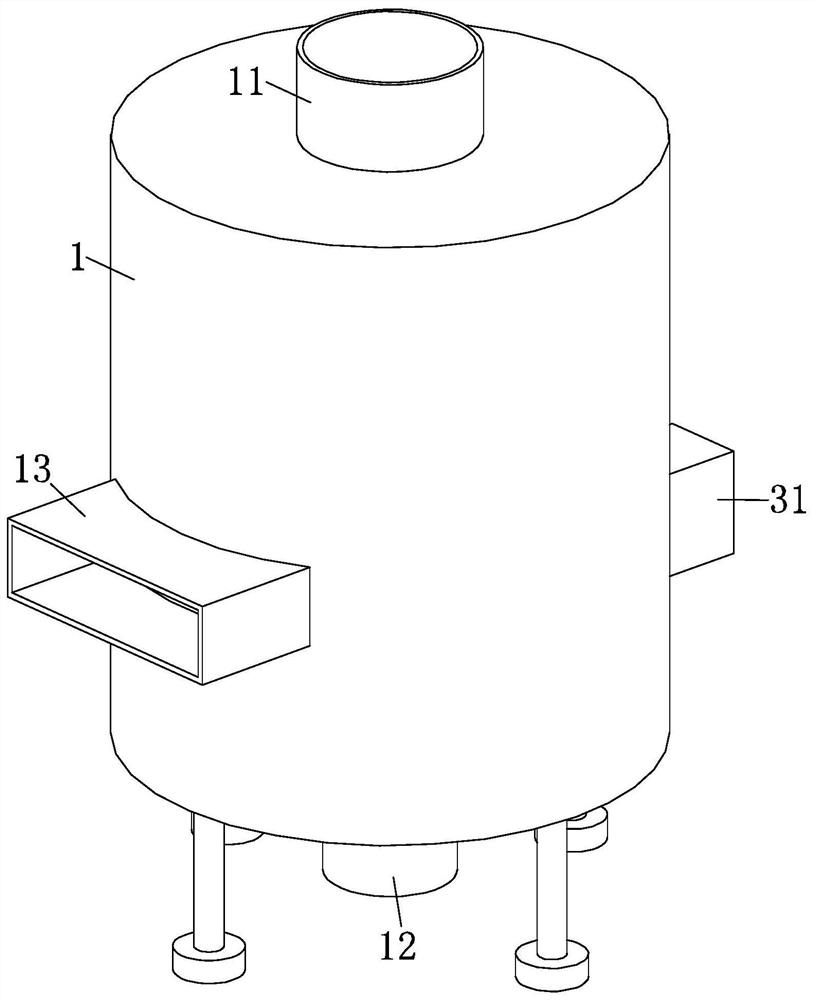

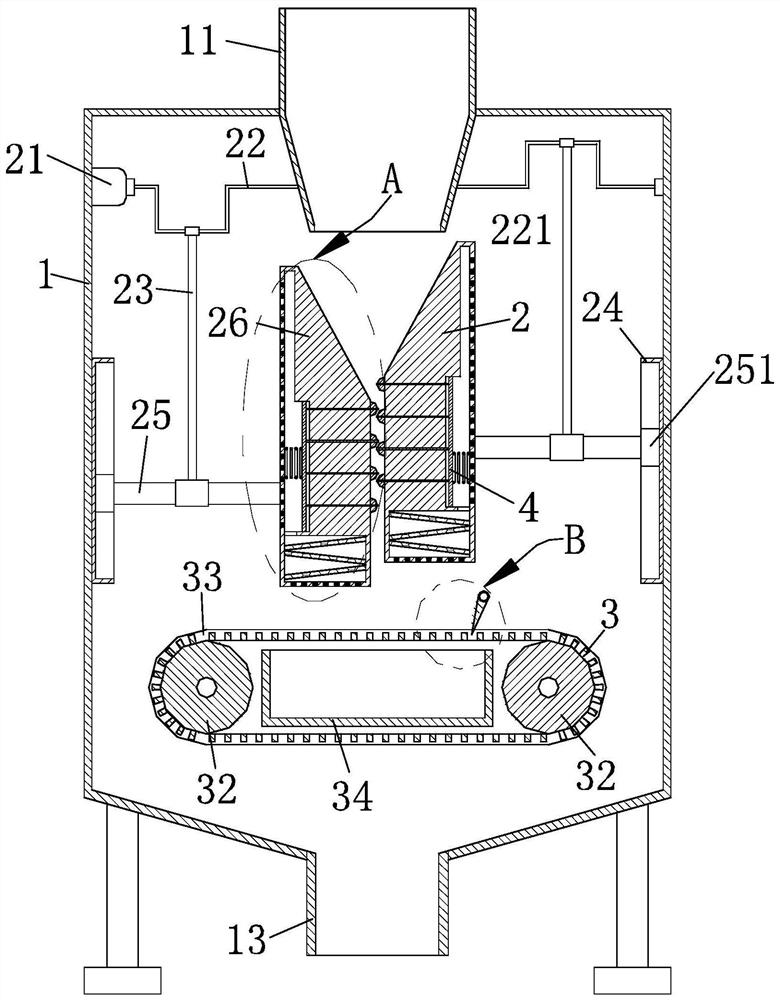

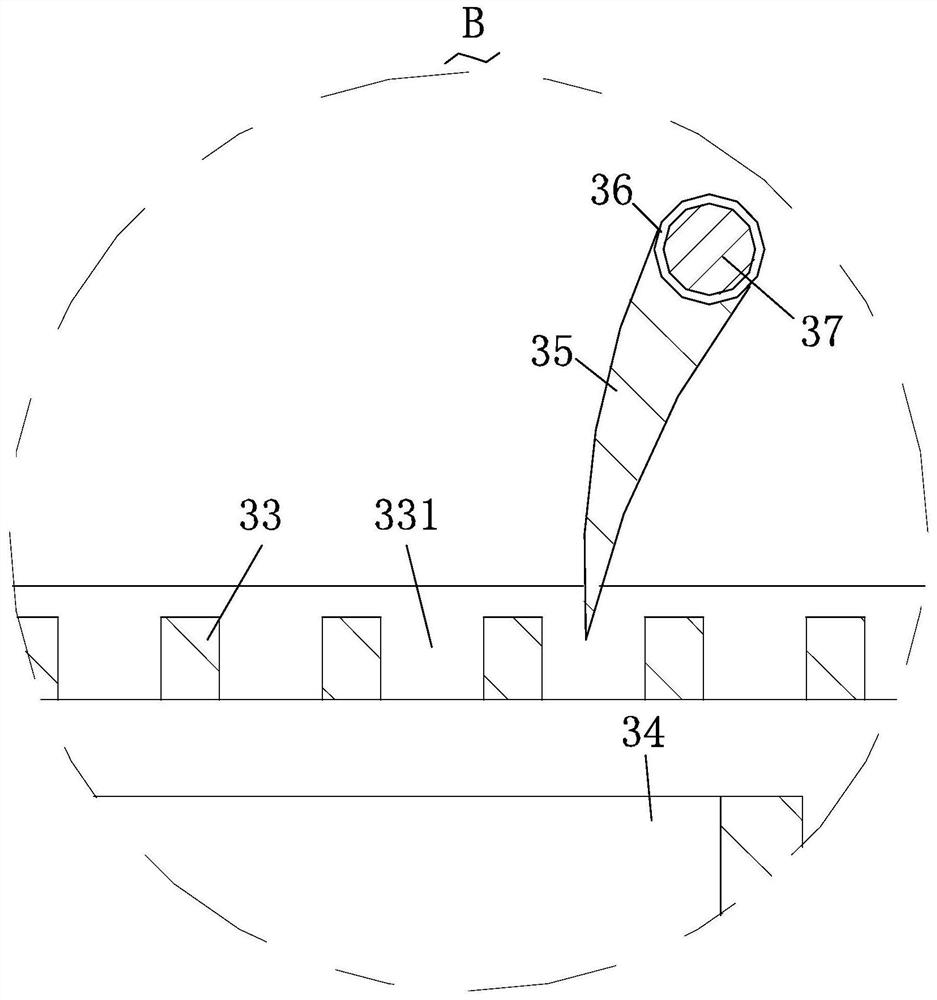

[0023] Such as Figure 1-Figure 6 As shown, a recycling machine for waste building materials according to the present invention includes a housing 1, the top of the housing 1 is provided with a feed port 11, the bottom of the housing 1 is provided with a steel bar discharge port 12, and the housing 1 is provided with a concrete outlet 13, and the housing 1 is provided with a crushing mechanism 2, a screening mechanism 3 and a dust removal mechanism 4. When working, the equipment is powered on, and the reinforced concrete blocks to be processed are added through the feed port 11. The reinforced concrete blocks are crushed by the crushing mechanism 2 and then fall into the screening mechanism 3, and then the concrete fragments are discharged from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com