Plastic recycling and water washing treatment equipment

A technology for washing treatment and plastic recycling, applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve problems such as large water consumption and water resource waste, and achieve the effect of saving washing water and reliable operation environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

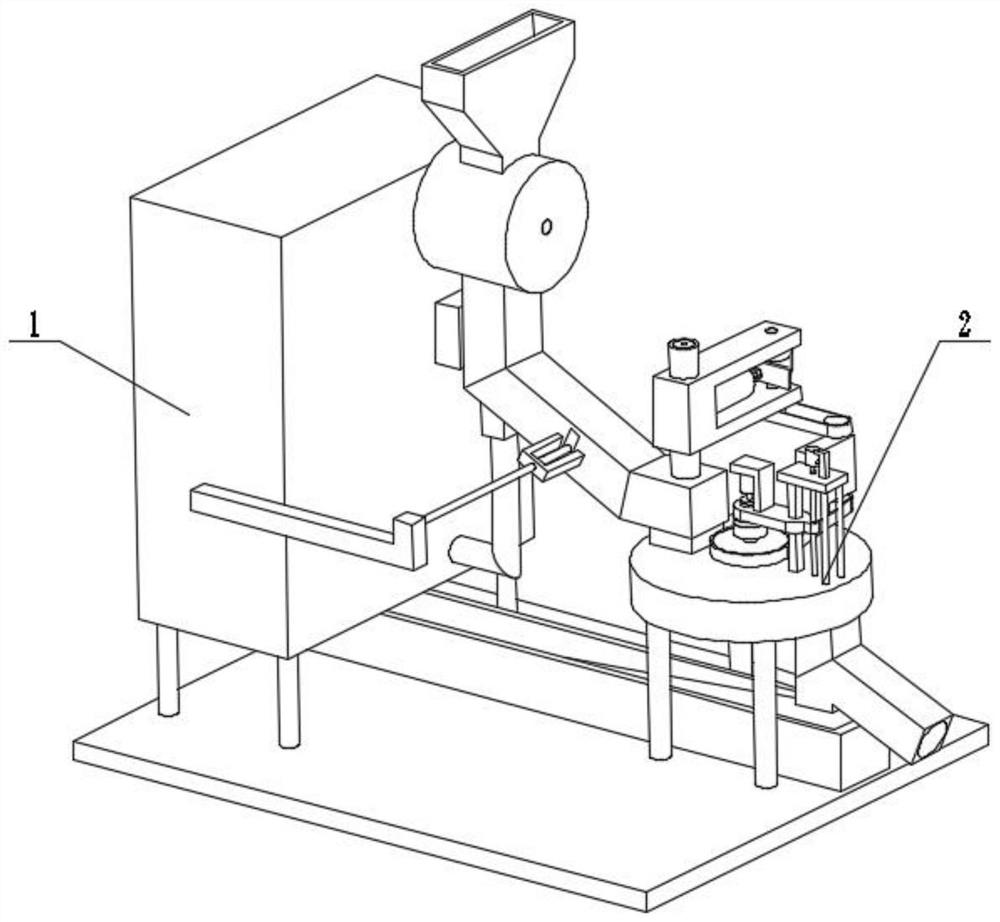

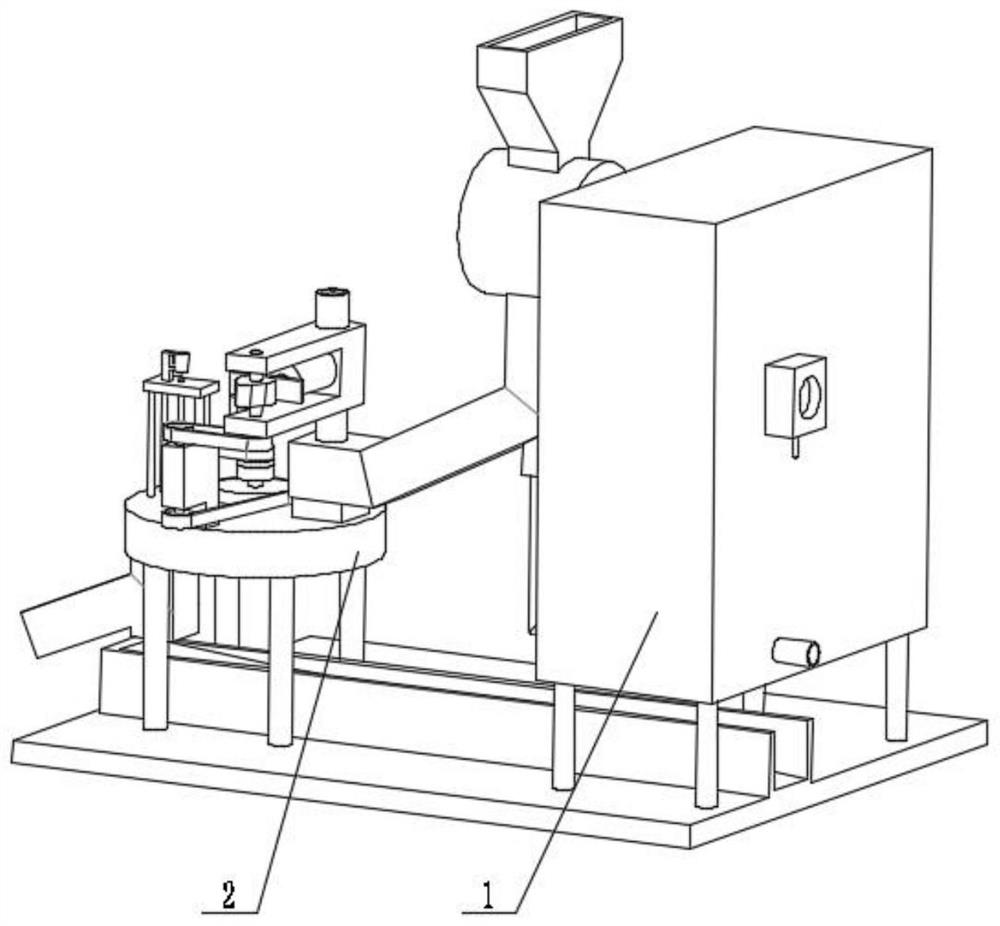

[0029] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 Describe this embodiment, the present invention relates to a kind of plastic recycling equipment, more specifically a kind of plastic recycling water washing treatment equipment, including air flow management anti-blocking mechanism 1, crushing mechanism 2, the equipment can be crushed, and the equipment can activate the crushed The equipment can ensure a more reliable operating environment, and the equipment can save water for washing.

[0030] The air flow control and anti-blocking mechanism 1 is connected with the crushing mechanism 2 .

specific Embodiment approach 2

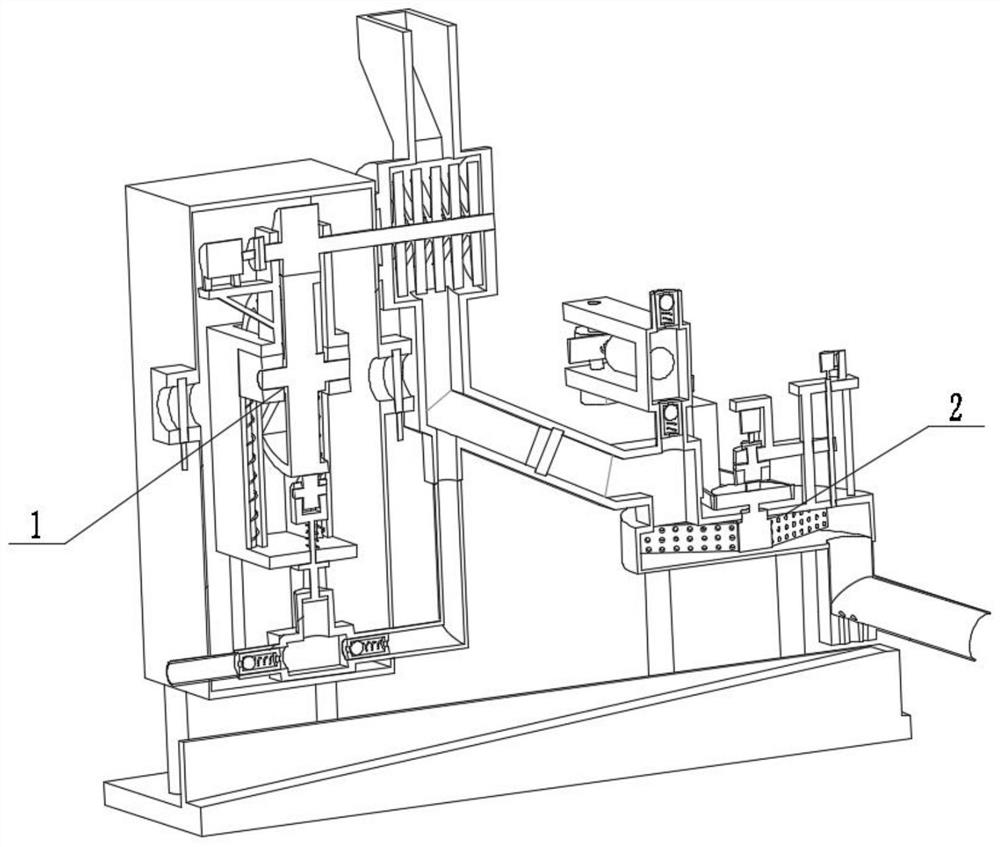

[0032] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 Describe this embodiment, this embodiment will further explain Embodiment 1, the air flow control and anti-blocking mechanism 1 includes a gate with a rod 1-1, a positive pressure pipe nozzle 1-2, a box body 1-3, and a connecting seat 1 -4. Outrigger 1-5, air outlet 1-6, crushing wheel 1-7, crushing shaft 1-8, inlet 1-9, air inlet pipe 1-10, cam 1-11, coupling 1- 12. Motor 1-13, fixed frame 1-14, belt shaft wheel 1-15, filter plate 1-16, movable bearing seat 1-17, chute 1-18, limit column 1-19, spring 1-20 , blade 1-21, belt pulley seat 1-22, return spring 1-23, inlet 1-24, intake check valve 1-25, transfer gas box 1-26, inner piston 1-27, outlet check valve Valve 1-28, seat post with limiter 1-29, positive pressure tube 1-30, filter plate I1-31, hinged arm 1-32, connecting se...

specific Embodiment approach 3

[0034] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14Describe this embodiment, this embodiment will further explain Embodiment 1. The crushing mechanism 2 includes a base 2-1, a water tank 2-2, a leg I2-3, a washing tank 2-4, and a delivery pipeline 2- 5. Hole seat 2-6, gate matching slideway 2-7, water outlet seat 2-8, crushing box 2-9, crushing entry bucket 2-10, water inlet check valve 2-11, water inlet pipe 2-12 , water body transfer box 2-13, piston tube 2-14, piston rod 2-15, spring I2-16, matching seat 2-17, belt shaft cam 2-18, pulley I2-19, belt 2-20, belt shaft Belt pulley I2-21, servo motor 2-22, secondary platform 2-23, lead screw 2-24, belt pulley III2-25, movable platform 2-26, limit column I2-27, secondary support leg 2-28, Washing motor 2-29, coupling I2-30, driving disc with protrusion 2-31, driven disc with shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com