Method for manufacturing a pressure-resistant liquid storage tank

A manufacturing method and technology for liquid storage tanks, which are used in packaging, large containers, transportation and packaging, etc., can solve the problems of tank deformation and instability, poor pressure bearing capacity, and easy deformation, and achieve uniform stress and less consumables. , The effect of not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

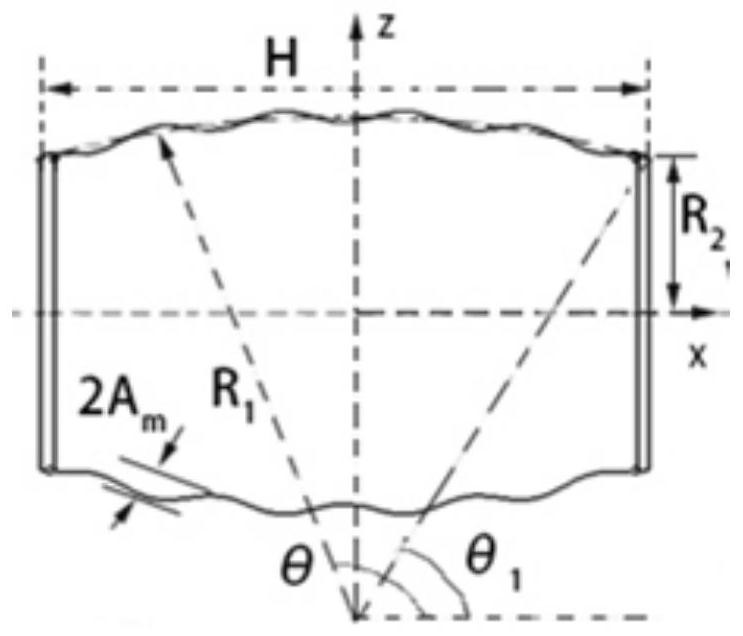

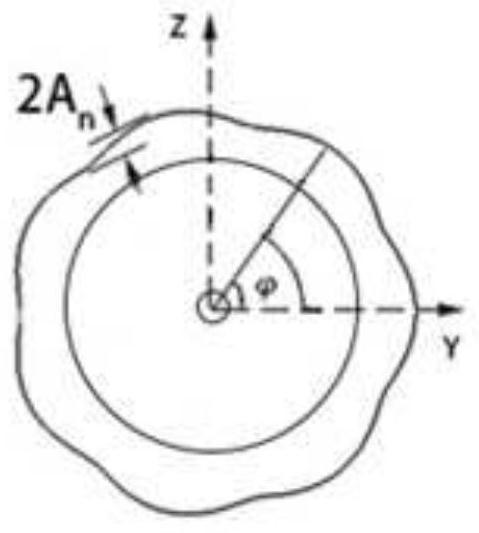

[0049] Such as Figure 1-3 As shown, a pressure-resistant liquid storage tank includes a water storage tank body and a head arranged at both ends of the water storage tank. The head at one end of the water storage tank is provided with a liquid inlet hole, and the tank wall of the water storage tank body is uniform in latitude and circumference. Satisfy the sine wave curve equation, record the height of the tank wall as H, and the radius of the radial circle as R 1 , the radius of the circumferential end face circle is R 2 , the amplitude of the sinusoid is A m and A n , the radial rotation angle is θ, and the circumferential rotation angle The numbers of radial and circumferential corrugations are a and b respectively, and the initial rotation angle is θ 1 , the equation of the radial sine wave curve of the tank wall is:

[0050] X(θ)=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com