Bacteriostatic suit fabric and preparation method thereof

A technology for fabrics and suits, applied in textile, biochemical fiber treatment, yarn, etc., can solve the problems of loss of antibacterial effect, antibacterial coating peeling off, weakening of antibacterial effect, etc., and achieve good dispersion and good antibacterial and antibacterial effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example a

[0038] A kind of nanometer silver antibacterial agent, adopts following method to make:

[0039] Weigh silver nitrate, sodium borohydride and mite-removing finishing agent and dissolve them in deionized water respectively, and configure silver nitrate solution with a mass concentration of 7g / L, 0.9g / L sodium borohydride solution and 50g / L mite-removing finishing agent Solution, add 36mL mite removal finishing agent solution to 8mL silver nitrate solution, use deionized water to make up to 50mL, stir magnetically for 30 minutes, add sodium borohydride solution dropwise until the reaction is complete, and finally add deionized water again to make up to 50mL , the prepared nano silver mass concentration is 750mg / L, and the average particle diameter is 20nm.

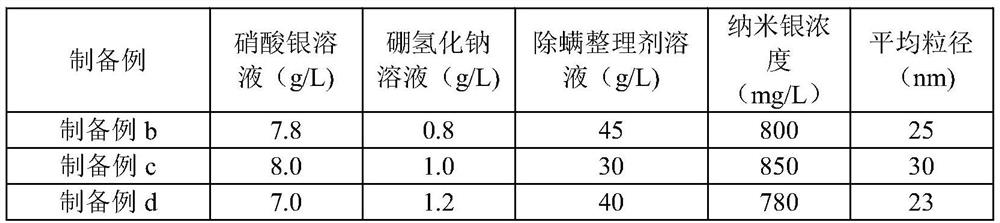

preparation example b-d

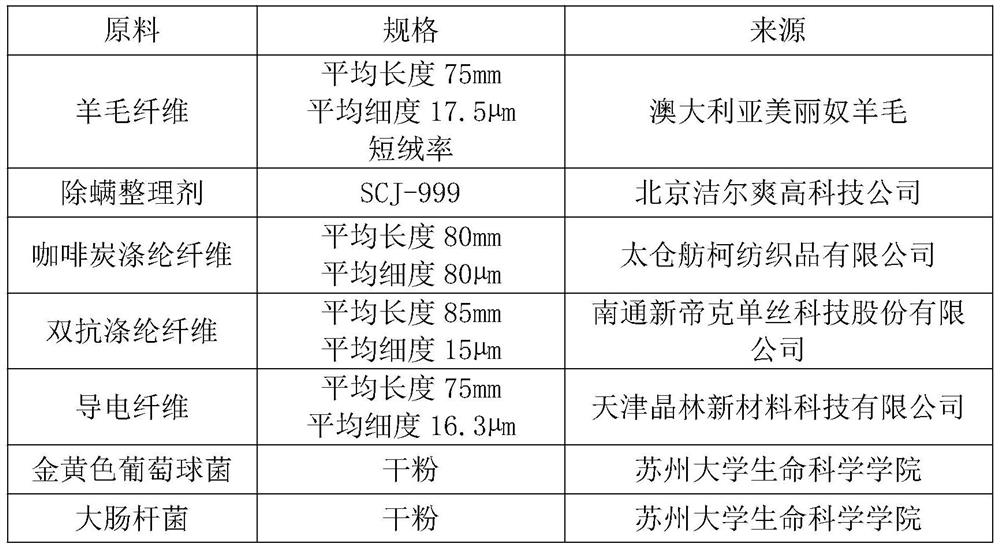

[0041] A nano-silver antibacterial agent, based on preparation example a, the difference mainly lies in the different concentrations of the raw materials used and the different concentrations of the obtained nano-silver solution, see Table 2 for details.

[0042] Table 2 preparation example b-d raw material concentration

[0043]

[0044] Preparation example of antibacterial wool fiber

preparation example 1

[0046] A kind of antibacterial wool fiber, adopts following method to make:

[0047] Get quantitative loose wool fiber and be placed in the deionized water that bath ratio is 1:50, add glacial acetic acid and regulate solution pH value to 5.0, add the nano-silver solution that makes in the preparation example a, the consumption of nano-silver solution is 2% ( owf), soak at 25°C for 10 minutes, then raise the temperature to 75°C at a rate of 1.0°C / min, keep it at this temperature for 20 minutes, then cool down to 25°C naturally, rinse with deionized water and place at 120°C Dry at ℃ to obtain antibacterial wool fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com