Method for processing and producing down jacket with aromatic odor

A technology of aromatic smell and production method, which is applied in the field of garment processing, can solve the problems of overly strong aromatic smell and poor fragrance persistence of down jackets, and achieve the effects of avoiding too strong fragrance, uniform emission rate, and prolonging the emission time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

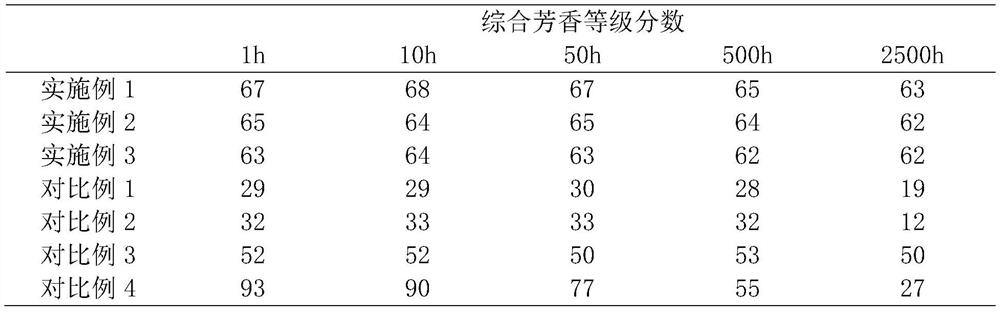

Examples

Embodiment 1

[0024] A method for processing and producing a down jacket with an aromatic smell, the steps comprising:

[0025] Step 1: Select goose down and use a laser to perform laser etching on the surface of the down with a laser pulse flux of 5J / cm 2 , the processing frequency is 5KHz, the down is constantly turned during the processing process, so that the surface of the down is uniformly etched, and the surface of the down is distributed with micron-sized holes;

[0026] Step 2: Select lavender essential oil, and carry out high magnetization treatment on the essential oil. The magnetic field strength of high magnetization treatment is 8000GS, and the treatment time is 80min, so that the essential oil particles are micronized;

[0027] Step 3: Soak the eider down obtained in step 1 in the essential oil obtained in step 2 at a soaking temperature of 40°C for 10 hours. During the soaking process, pressurize the soaking system so that the pressure of the soaking system is 0.8 MPa. Sepa...

Embodiment 2

[0031] A method for processing and producing a down jacket with an aromatic smell, the steps comprising:

[0032] Step 1: Select duck down and use a laser to perform laser etching on the surface of the down, and the laser pulse flux is 10J / cm 2 , the processing frequency is 3KHz, the down is constantly turned during the processing process, so that the surface of the down is uniformly etched, and the surface of the down is distributed with micron-sized holes;

[0033] Step 2: select tea tree oil, and carry out high magnetization treatment on the essential oil. The magnetic field strength of high magnetization treatment is 13000GS, and the treatment time is 50min, so that the essential oil particles are micronized;

[0034] Step 3: Soak the eiderdown obtained in step 1 in the essential oil obtained in step 2 at a soaking temperature of 50°C for 5 hours. During the soaking process, pressurize the soaking system so that the pressure of the soaking system is 0.8 MPa. Separate the ...

Embodiment 3

[0038] A method for processing and producing a down jacket with an aromatic smell, the steps comprising:

[0039] Step 1: Select goose and duck mixed down, use a laser to perform laser etching on the surface of the down, and the laser pulse flux is 15J / cm 2 , the processing frequency is 0.5KHz, and the down is constantly turned during the processing process, so that the surface of the down is uniformly etched, and the surface of the down is distributed with micron-sized holes;

[0040] Step 2: Select rose essential oil, and carry out high-magnetization treatment on the essential oil. The magnetic field strength of high-magnetization treatment is 20000GS, and the treatment time is 20 minutes, so that the essential oil particles are micronized;

[0041] Step 3: Soak the eiderdown obtained in step 1 in the essential oil obtained in step 2 at a temperature of 60°C and for 1 hour. During the soaking process, the soaking system is pressurized so that the pressure of the soaking syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com