Stabilized fire cover and cooker burner including same

A burner and voltage stabilization technology, applied in burners, gas fuel burners, combustion types, etc., can solve problems such as uneven pressure, obstructed combustion conditions, and different flame lengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

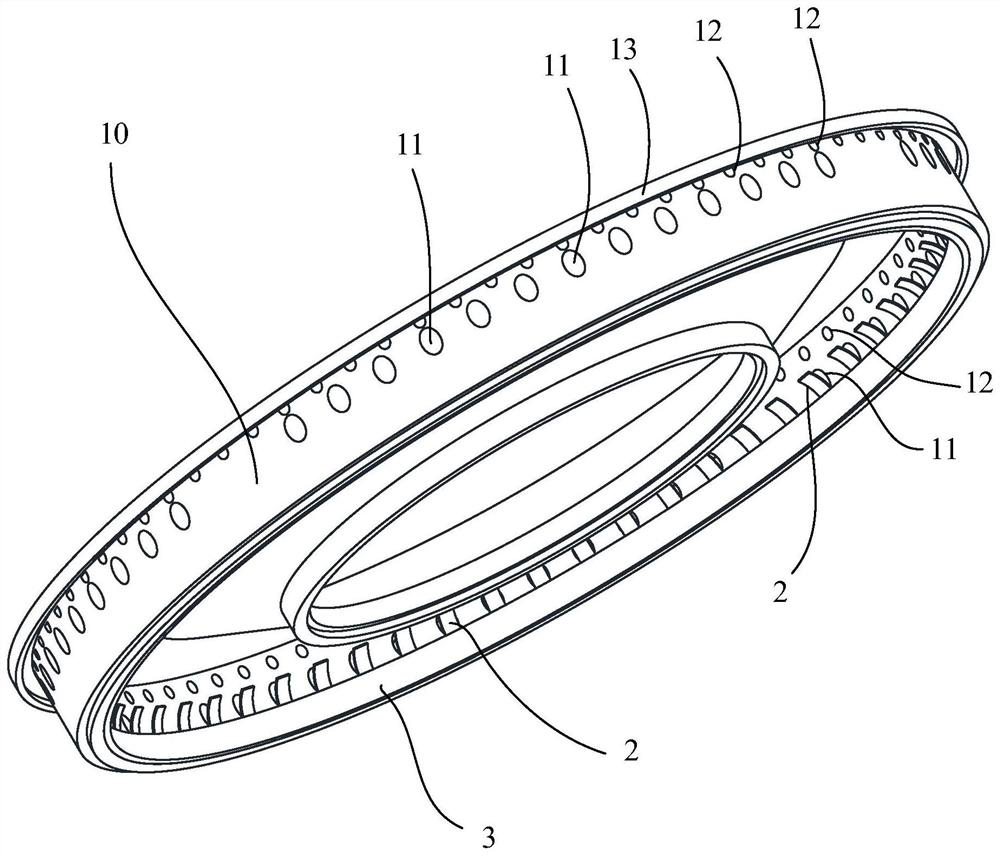

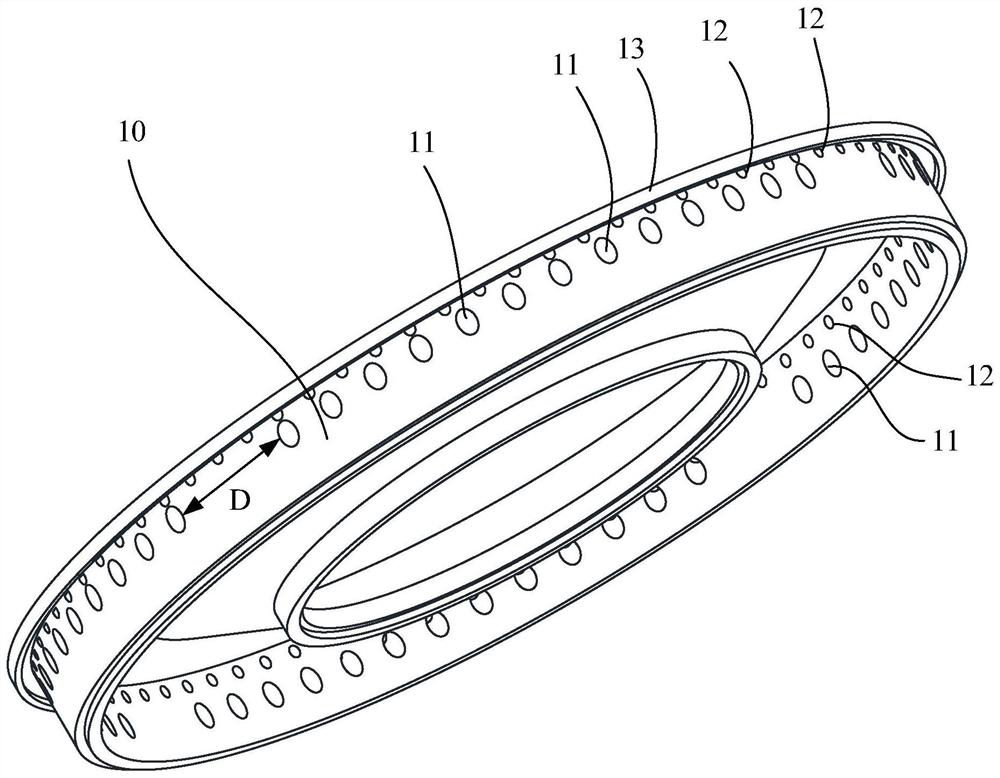

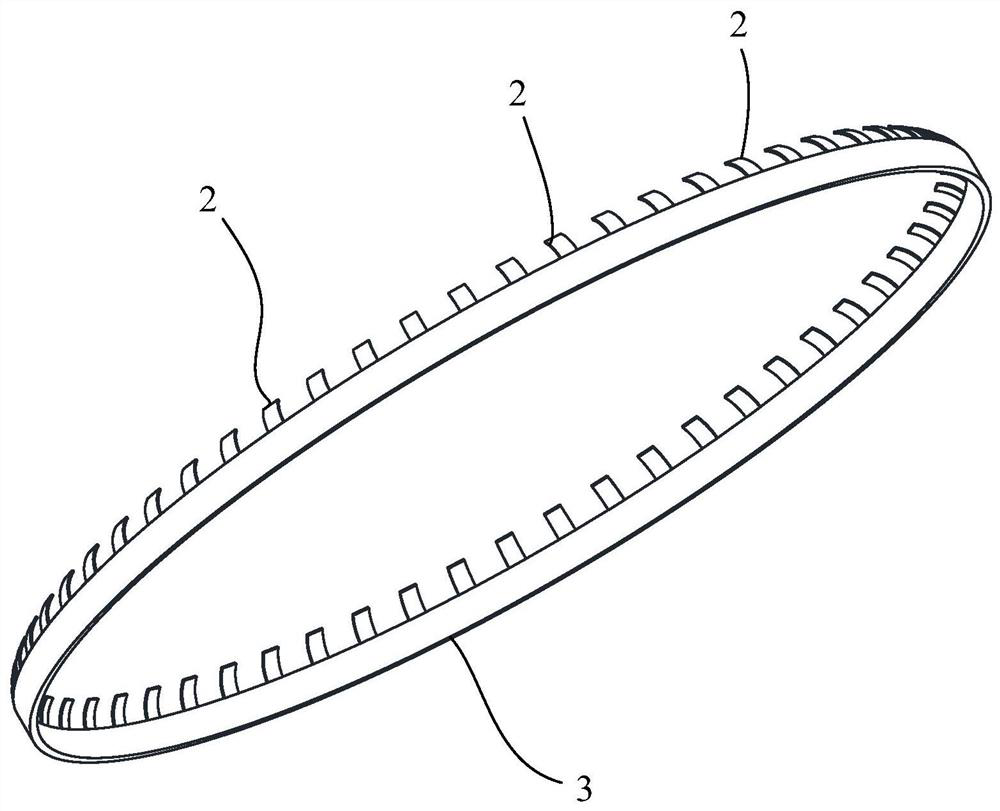

[0026] like Figure 1-Figure 5 As shown, the present embodiment discloses a pressure-stabilizing fire cover, including a fire cover body 10 and a main fire hole 11 arranged on the fire cover body 10, wherein the pressure-stabilizing fire cover also includes a fire cover body 10 arranged inside The voltage stabilizing shrapnel 2. Among them, such as figure 1 and Figure 5 As shown, the pressure stabilizing shrapnel 2 of this embodiment corresponds to the position of the main fire hole 11, and the voltage stabilizing shrapnel 2 blocks the main fire hole 11 in the air intake direction, and the voltage stabilizing shrapnel 2 has elastic force so that the Change the gap with the main fire hole 11.

[0027] In the present invention, by adding a pressure-stabilizing shrapnel 2 inside the main fire hole 11, each main fire hole 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com