A composite structure surface in the field of enhanced radiative cooling

A composite structure, radiation refrigeration technology, applied in refrigerators, refrigeration and liquefaction, chemical instruments and methods, etc., can solve the problems of poor spectral radiation characteristics, complex surface design of radiation structures, etc., and achieve the effect of simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

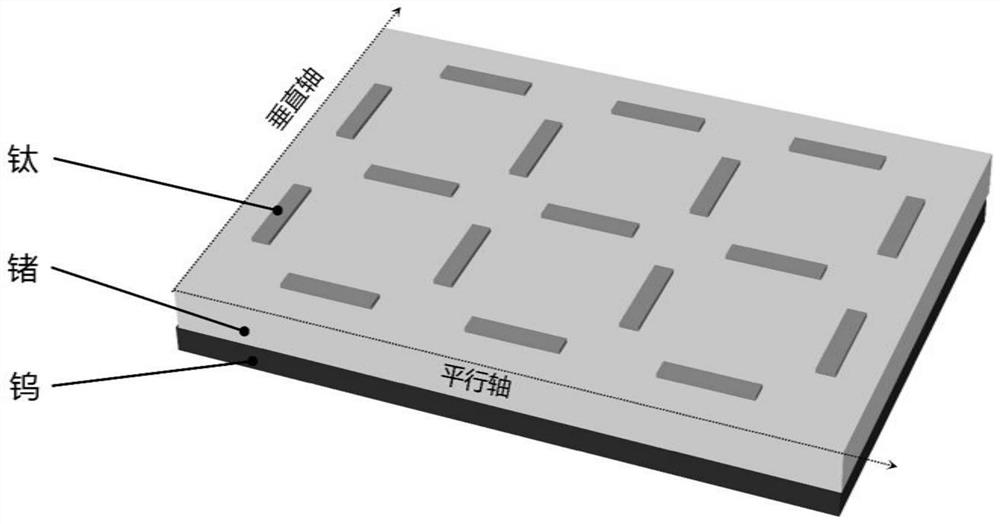

[0016] The present invention is based on the range of 50-100°C. Considering that the thermal radiation is mainly concentrated in the near-middle infrared region, a composite structure surface based on titanium-germanium-tungsten is proposed.

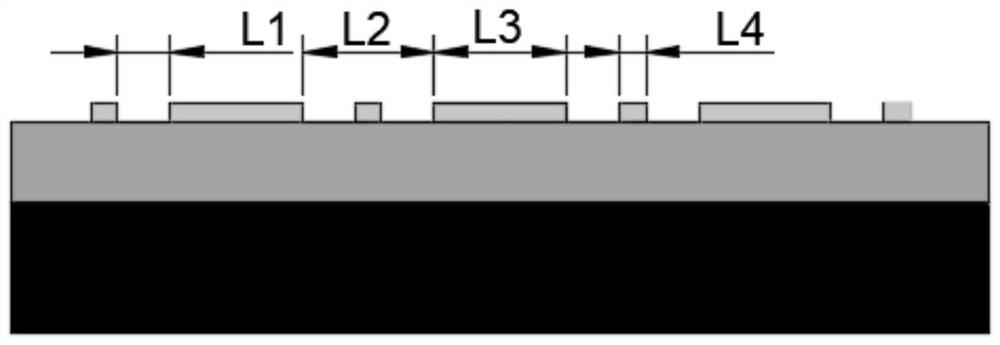

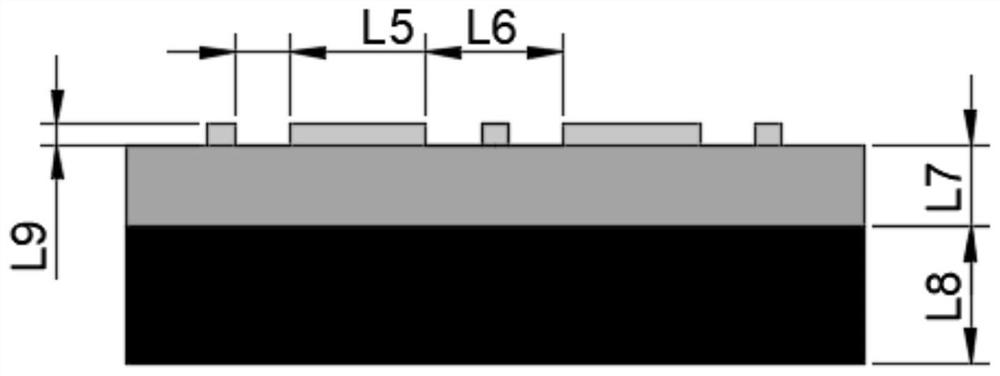

[0017] The thickness L8 of the metal tungsten substrate is 2-2.5 μm, the semiconductor germanium dielectric layer L7 is 0.6-0.8 μm; the length L3 of the titanium metal strip is 1-1.2 μm, the width L4 is 0.2-0.25 μm, and the height L9 is 0.06-0.08μm; vertical and parallel titanium metal strips are staggered; the distance between parallel titanium metal strips in the parallel direction L2 is 1μm, and the distance between vertical titanium metal strips in the parallel direction is L3+2L1 is 1.8-2μm; the vertical titanium metal strips are in the vertical direction The distance L6 is 1 μm, and the distance L3+2L5 in the vertical direction of the parallel titanium strips is 1.8-2 μm.

[0018] In the titanium-germanium-tungsten micro-nano comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com