Flexible strain sensor based on same conductive material and preparation method thereof

A technology of strain sensor and conductive material, applied in the field of sensors, can solve the problems of complex production process of flexible strain sensor, difficult to achieve mass production, etc., to achieve convenient integration in external equipment, high commercial value and industrialization prospects, and reduce noise interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

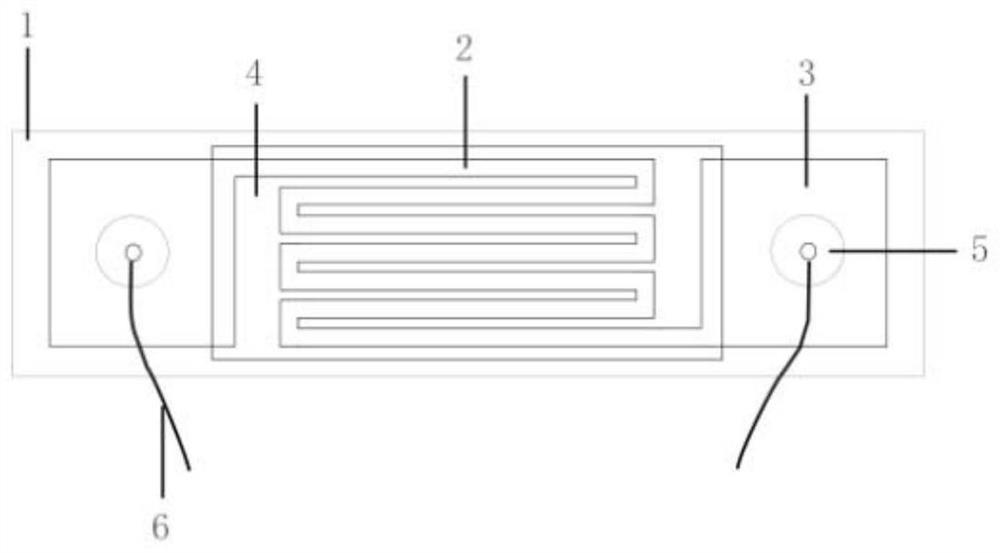

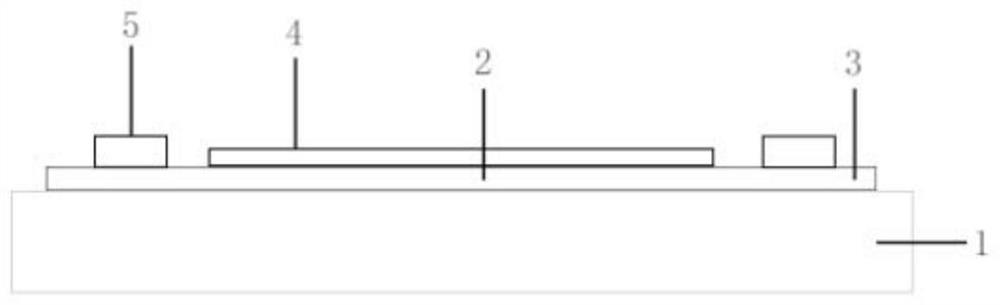

[0028] combine figure 1 and 2 , the flexible strain sensor in this embodiment is a layered structure, including a flexible substrate 1 on the bottom layer, a sensing region 2 and a connecting region 3 on the flexible substrate 1, an encapsulation layer 4 for protecting the sensing region 2, and a Accessories for electrical connection, including metal buttons 5 and wires 6. The sensing area and connection area are the middle layer, and the encapsulation layer is the top layer.

[0029] Both the sensing area and the connecting area are made of the same conductive material, and the sensor based on the same conductive material can be printed in one step through a screen printing process instead of in steps. That is to say, the sensing area and the connection area are made of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com