Protection method and protection equipment for motor of electric vehicle

A technology for protective equipment and electric vehicles, applied in electric vehicles, motors, electric components, etc., can solve problems affecting the service life of motors and increase the temperature of the housing, and achieve the effects of prolonging service life, improving efficiency, and expanding the range of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

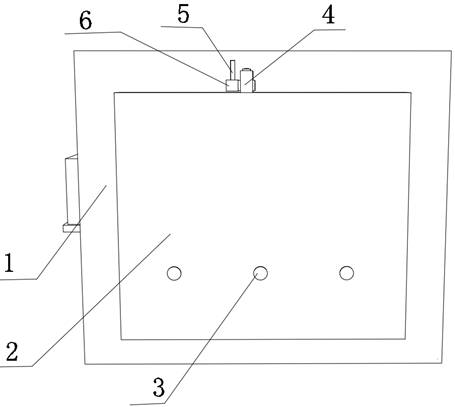

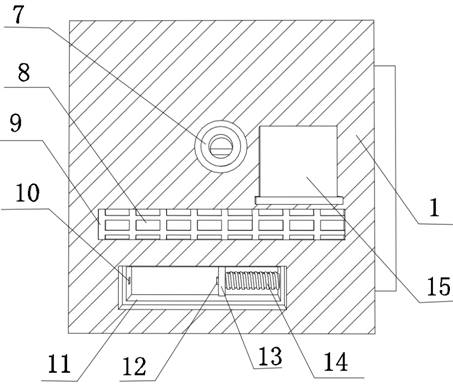

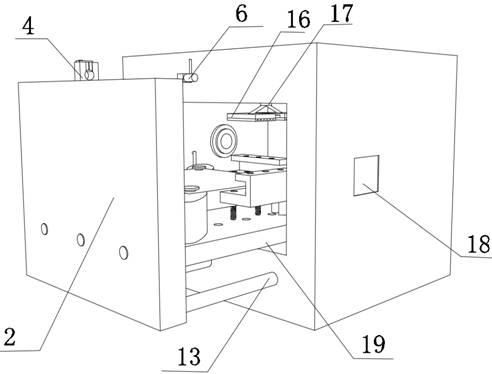

[0041] Protective equipment for electric vehicle motor, such as figure 2 , image 3 with Figure 5 As shown, including the housing 1, the outer wall of the housing 1 is coated with a preservative layer 22; the inner wall of the housing 1 is bonded to the elastic layer 27, and the inner wall of the elastic layer 27 is welded to the inner casing 30; the shell The outer wall of the body 1 opens an inlet 8, and the inner wall of the intake port 8 is fixed by the bolt 9, and the outer wall of the filter 9 is fixed by the screw, and the housing 1 is On the outer wall is connected to a water tank 15 by a fixing plate, the output of the water tank 15 is connected by a conduit, and the inner wall of the inner casing 30 is fixed by bolt, and a sponge block 24 is fixed, and the outer wall of the sponge block 24 passes The bolt is secured with a dry plate 25; the other side wall of the housing 1 secures the heat dissipation opening 18 by bolts; the inner wall of the inner casing 30 is fixed wit...

Embodiment 2

[0047] Prevention method of protective equipment for electric vehicle motor, such as figure 1 As shown, including the following steps:

[0048] S1: Pull the box door 2, adjust the three slider 13 in the three limit box 11, the motor is placed in the adjustment mounting structure on the reinforcing plate 20;

[0049] S2: Adjust the top surface of the control of the elastic pressure plate 16, the shock absorbing airbag 29 is fitted with the motor side faces its limit;

[0050] S3: Motors for shock absorption and noise reduction protection by shock absorbing assembly 39, cushion 37, and elastic layer 27 or the like;

[0051] S4: The filtered gas stream is introduced by the fan 28, so that the sponge block 24, cooling and dehumidifying the inner casing 30 after the spray head 23 is cooled, and the space of the inner casing 30 is lowered;

[0052] S5: At the same time, the heat pipe 41 generates heat conduction generated by the motor job through the heat pipe 41.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com